Single worm over run clutch and its stepless speed variator

An overrunning clutch and continuously variable transmission technology, applied in one-way clutches, clutches, gear transmissions, etc., can solve problems such as high machining accuracy requirements, numerous parts of double worm overrunning clutches, and restricting market competition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

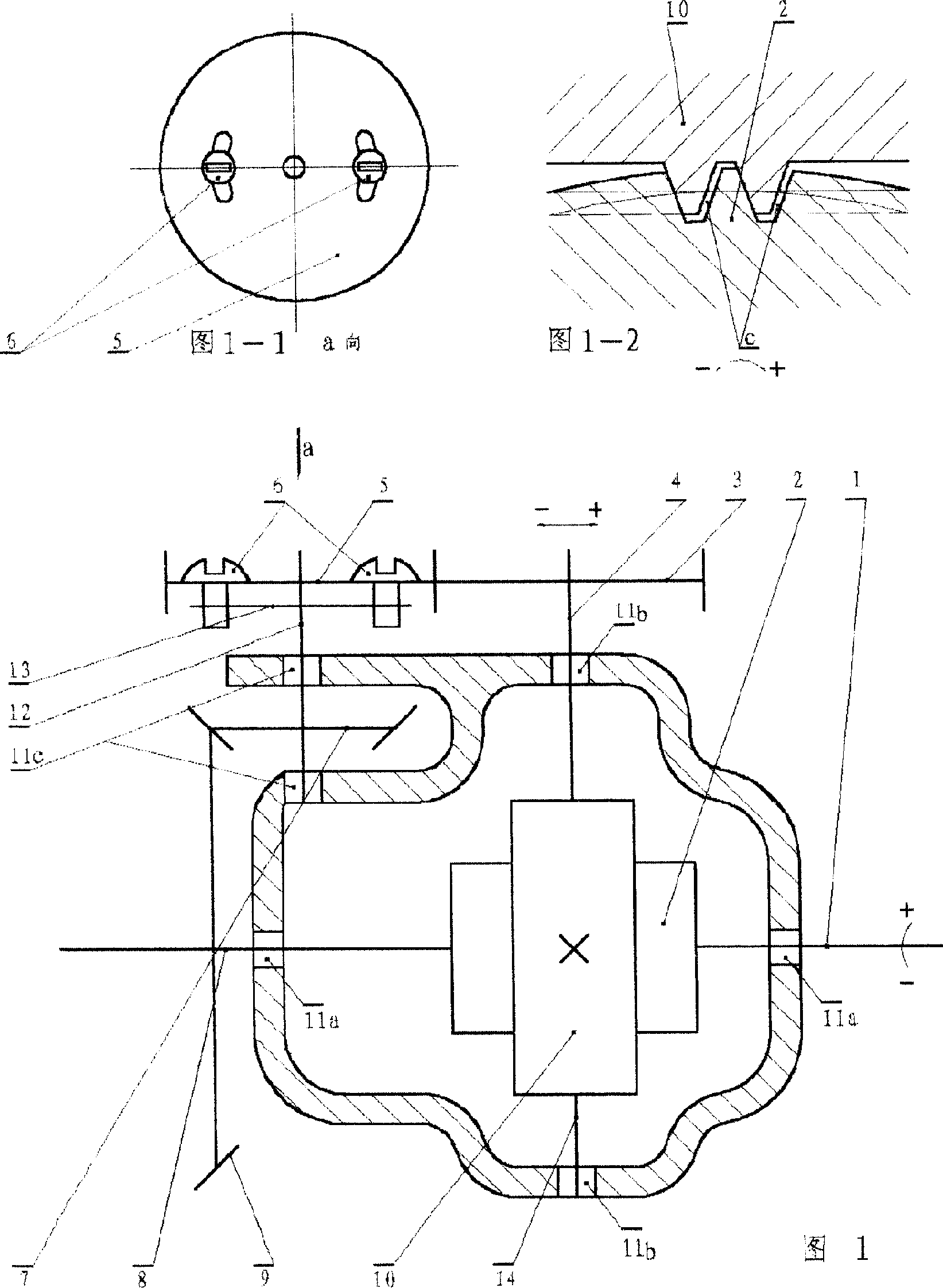

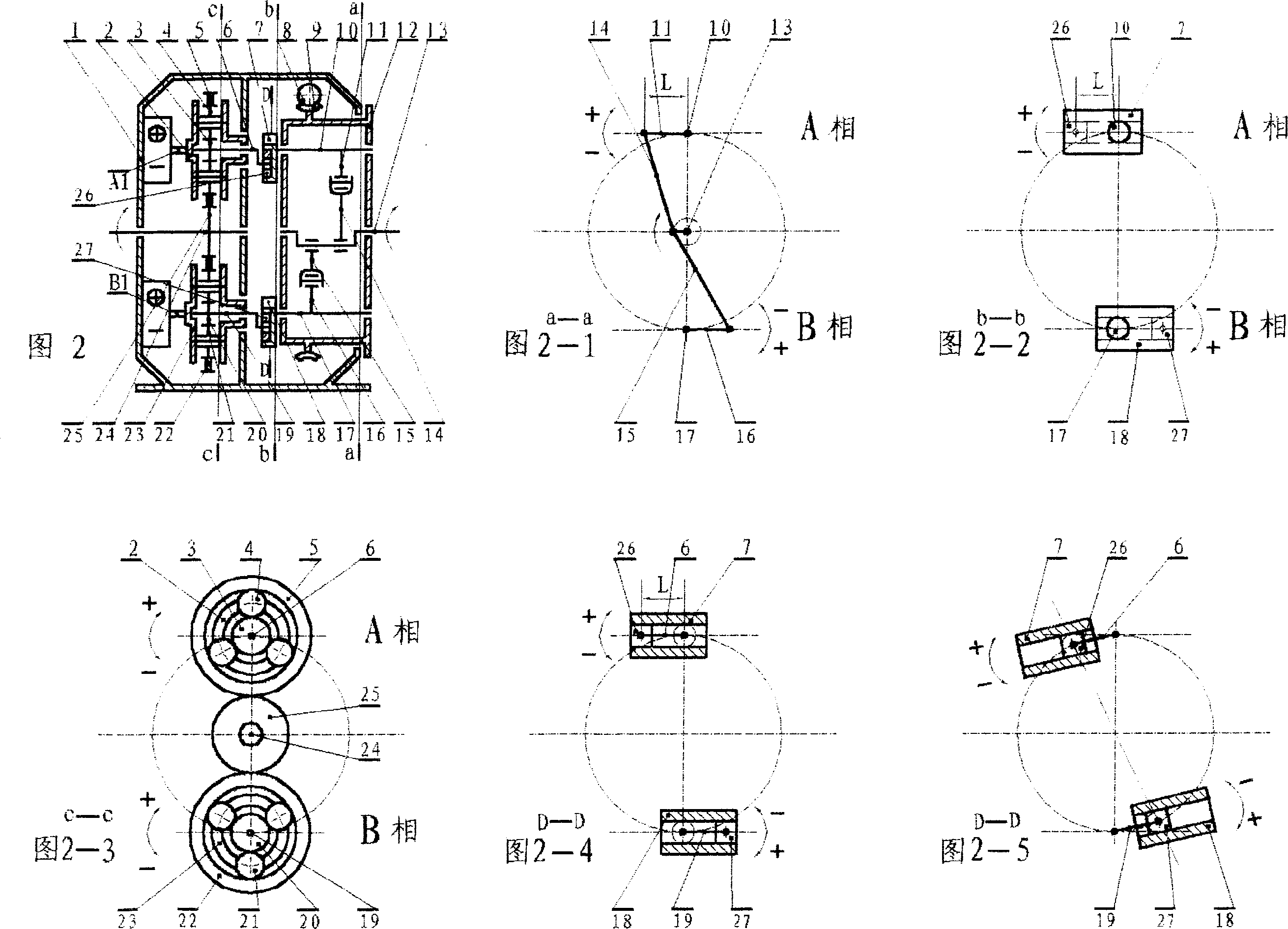

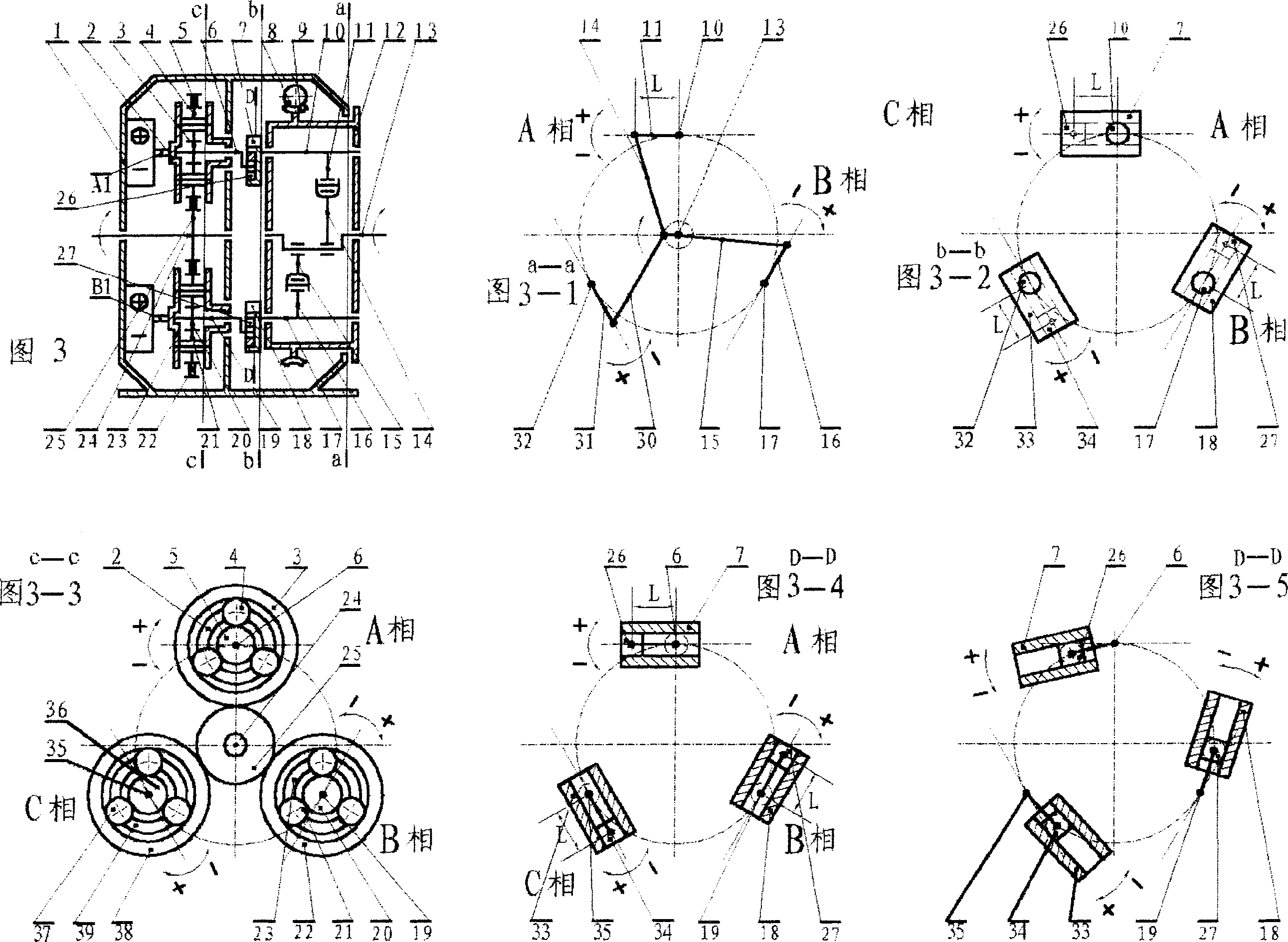

[0025] 1. Description of single worm overrunning clutch

[0026] 1. Structure description

[0027] As shown in FIG. 1 : the worm gear 2 is assembled in the volute shaft hole 11 a through the worm gear shafts 1 and 8 . The worm gear shaft 8 is fixedly connected with the bevel gear 9 and meshed with the bevel gear 7 with a key. The shaft 12 of the bevel gear 7, the disk 13 is an integral component (according to the needs of the process, it can also be made into discrete components and assembled into a fixed assembly) and is assembled in the volute shaft hole 11c. The gear 5 is concentrically assembled on the disc 13 through the screw 6 and meshed with the gear 3 . The plane of the gear 5 is milled into a waist groove at the fastening hole of the screw 6, which is used for fine-tuning the left or right offset of the meshing of the worm screw and the tooth surface of the worm gear during assembly. The worm 10 is fitted with shafts 4, 14 in the volute shaft hole 11b. The gear 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com