Method for preparing ultra filtration membrane in hollow fiber made from PVC with high flux

A polyvinyl chloride and ultrafiltration membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as little research, achieve excellent performance, wide industrial application prospects, high-purity water permeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

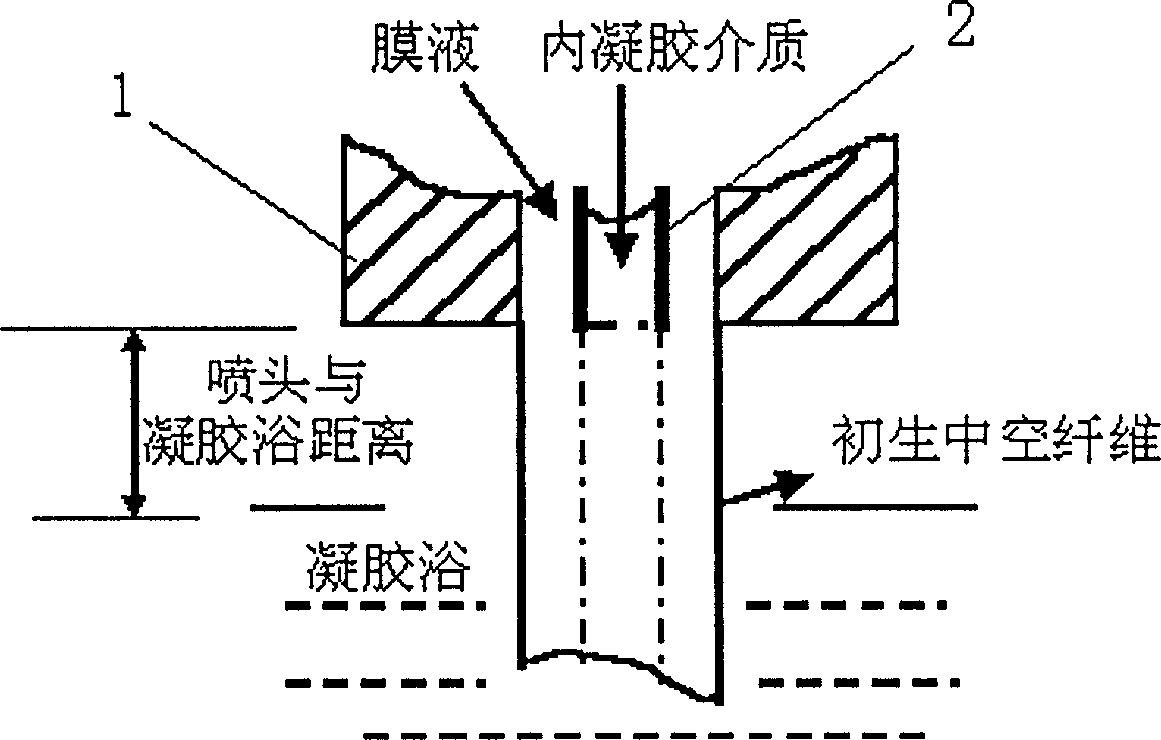

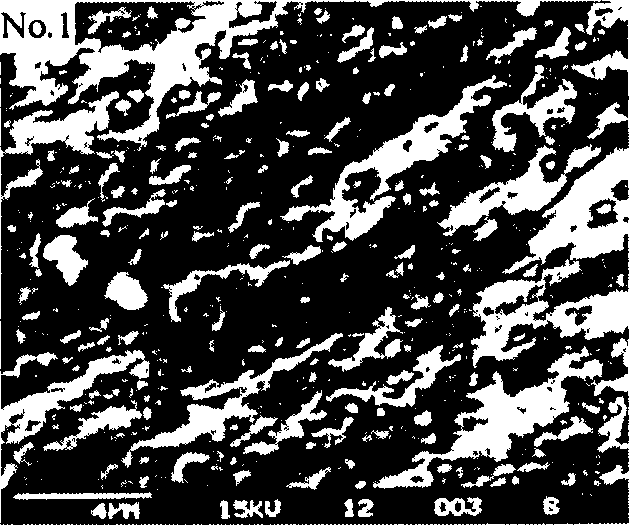

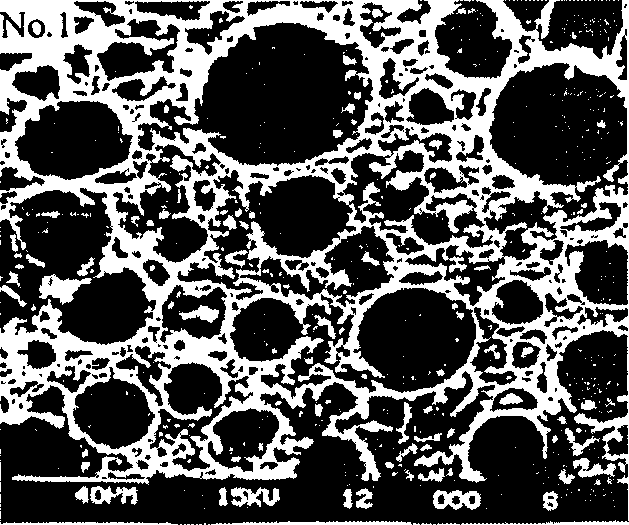

[0027] Weigh raw materials according to the following weight percentages, PVC (1300): 14%; DMAC: 81% and PVP: 5% are mixed with film-making solution, and its process is: first add 5% PVP in 81% DMAC and stir to dissolve, wait After the PVP is completely dissolved, add 14% PVC and stir to dissolve. Leave it for 72 hours at a temperature of 25°C. The prepared film-making solution was poured into the material tank and left to stand for 24 hours for degassing. The size of the nozzle is 0.5 mm in diameter of the inner tube 2, and 0.8 mm in the inner diameter of the outer tube 1. The film-forming liquid is sprayed from the annular gap of the nozzle, and the temperature is controlled at 25°C. M / min coiling speed for winding bundles into filaments. The inner gel medium is injected into the center of the nascent hollow fiber with a metering pump to form a hollow. The inner gel medium is 95% DMAC aqueous solution, and the outer gel bath is pure water. 25°C. The spun hollow fiber mem...

Embodiment 2

[0029] According to the preparation process and conditions described in Example 1, PVC (1300): 14%; DMAC: 81% and PVP: 5% were prepared as a film-forming solution. Preparation process as described in Example 1. Except for changing the inner gel solution into pure water, other process conditions were the same as in Example 1 to produce a hollow fiber membrane, which was treated and assembled into an ultrafilter with the same protection.

Embodiment 3

[0031] According to the preparation process and conditions described in Example 1, but the film-making liquid adopts the following weight percentages, PVC (1300): 12%; DMAC: 81% and PVP: 5%, others are the same as Example 1, repeat the process of Example 1 to obtain a hollow fiber membranes and assembled into ultrafilters.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com