Separation membrane, and method for producing same

一种制造方法、分离膜的技术,应用在半透膜分离、化学仪器和方法、膜等方向,能够解决未暗示等问题,达到化学和物理强度优异、高病毒除去性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

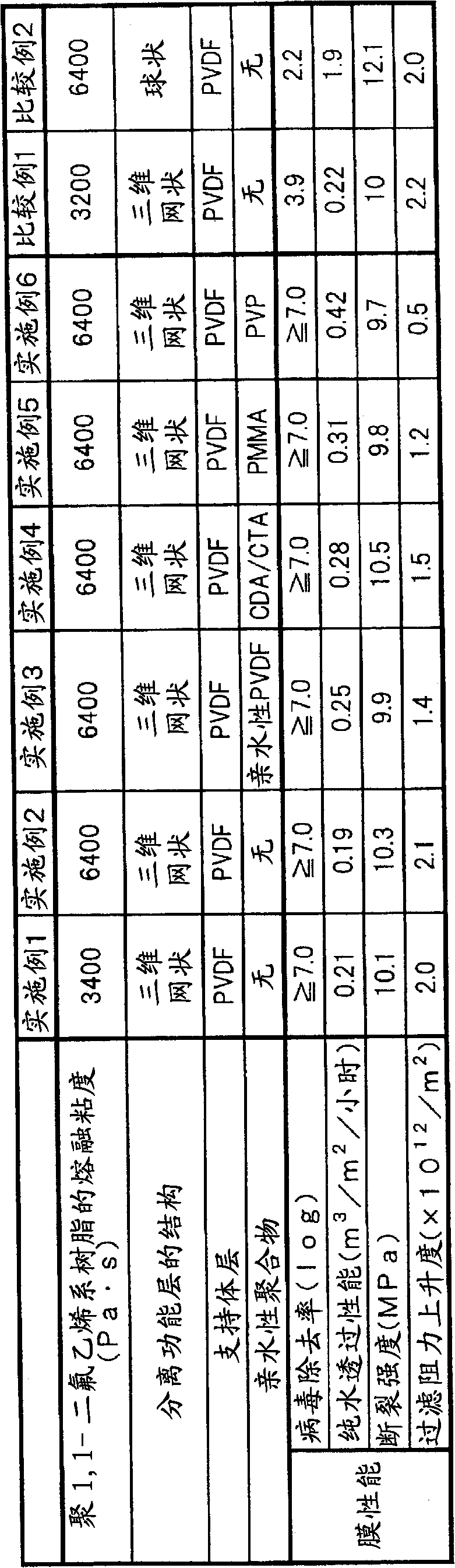

Embodiment 1

[0125]38% by weight of vinylidene fluoride homopolymer having a weight average molecular weight of 417,000 and 62% by weight of γ-butyrolactone were dissolved at 160°C. This polymer solution is discharged from the outer tube of double tube type die head, simultaneously γ-butyrolactone 85% by weight aqueous solution is discharged from the inner side tube of double tube type die head, makes them in by containing 85% by weight gamma-butyrolactone It is solidified in a bath composed of an aqueous ester solution at a temperature of 10°C. The resulting film was stretched to 1.5 times in water at 90°C. The obtained membrane was a hollow fiber membrane having a spherical structure, and this membrane was used as a support.

[0126] Next, polyvinylidene fluoride homopolymer (manufactured by Alkema Corporation, Kynar (registered trademark) HSV900) with a melt viscosity of 6400 Pa·s was mixed with 9.6% by weight of polyvinyl difluoride with a melt viscosity of 3200 Pa·s. Vinyl fluoride ...

Embodiment 2

[0128] Polyvinylidene fluoride homopolymer (manufactured by Alkema Corporation, Kynar (registered trademark) HSV900) with a melt viscosity of 6400 Pa·s was dissolved in N-methyl-2-pyrrolidone at 12% by weight to obtain separation Membrane stock solution for functional layer. This membrane-making stock solution was uniformly coated on the surface of the hollow fiber membrane obtained in Example 1, and then solidified in water at 23°C, thereby producing a separator with a three-dimensional network structure formed on a support layer with a spherical structure. A hollow filament separation membrane with a functional layer. Table 1 shows the membrane structure and membrane performance of the obtained separation membrane.

Embodiment 3

[0130] Polyvinylidene fluoride homopolymer (manufactured by Alkema Corporation, Kynar (registered trademark) HSV900) with a melt viscosity of 6400 Pa·s was mixed with maleic anhydride-modified polyvinylidene fluoride in an amount of 9.6% by weight. "Alkema Corporation, Kynar (registered trademark) ADX-111" was dissolved in N-methyl-2-pyrrolidone at 2.4% by weight to obtain a membrane-forming stock solution for separating functional layers. This membrane-making stock solution was uniformly coated on the surface of the hollow fiber membrane obtained in Example 1, and then solidified in water at 23°C to produce a separation function in which a three-dimensional network structure was formed on a support layer with a spherical structure. Layered hollow filament separation membrane. Table 1 shows the membrane structure and membrane performance of the obtained separation membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com