Corrugated paper support board

A corrugated paper and pallet technology is applied in the field of corrugated pallets, which can solve the problems of the impact of diseases and insect pests and high cost, and achieve the effects of being easy to put into production, simple in structure and low in production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

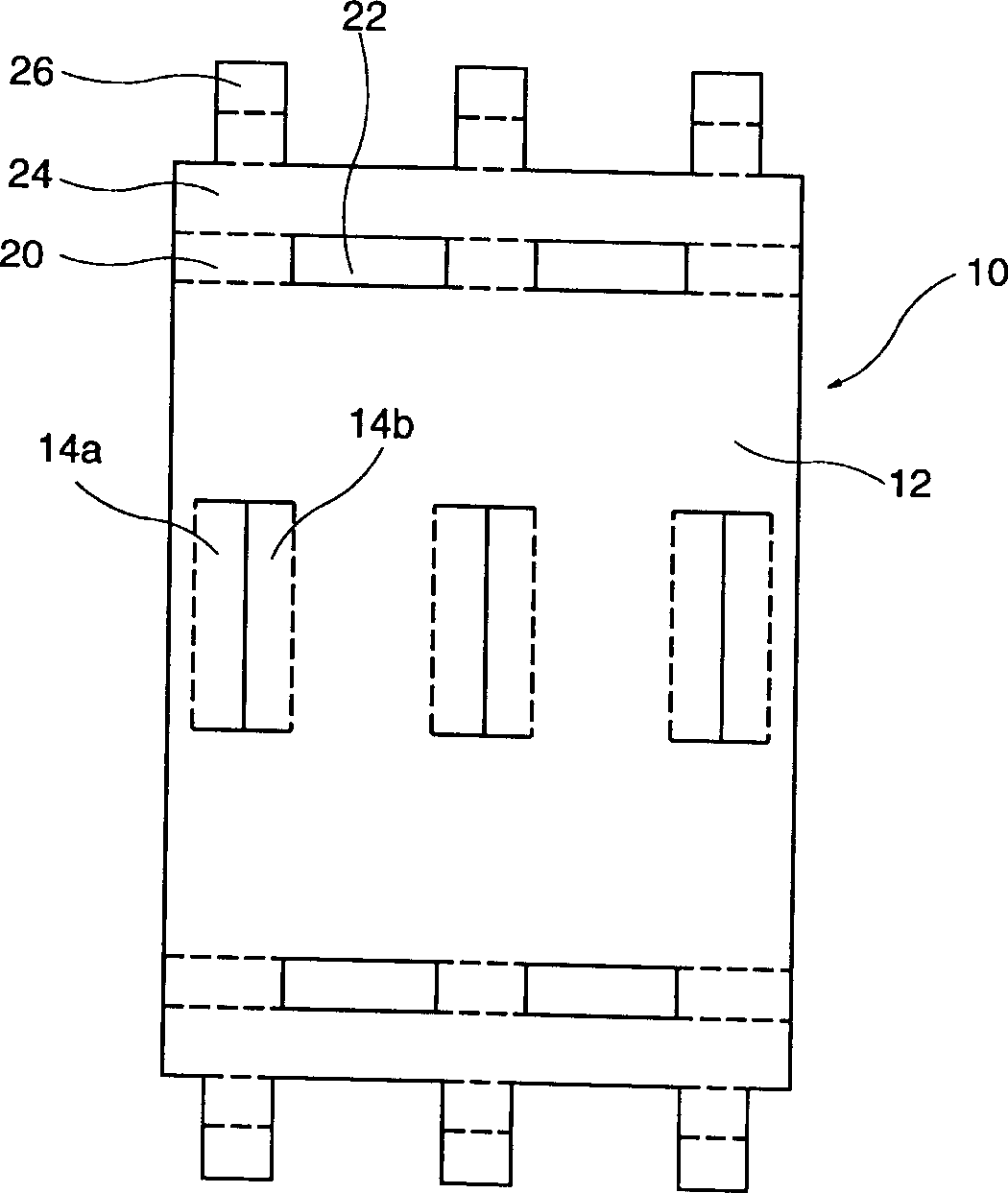

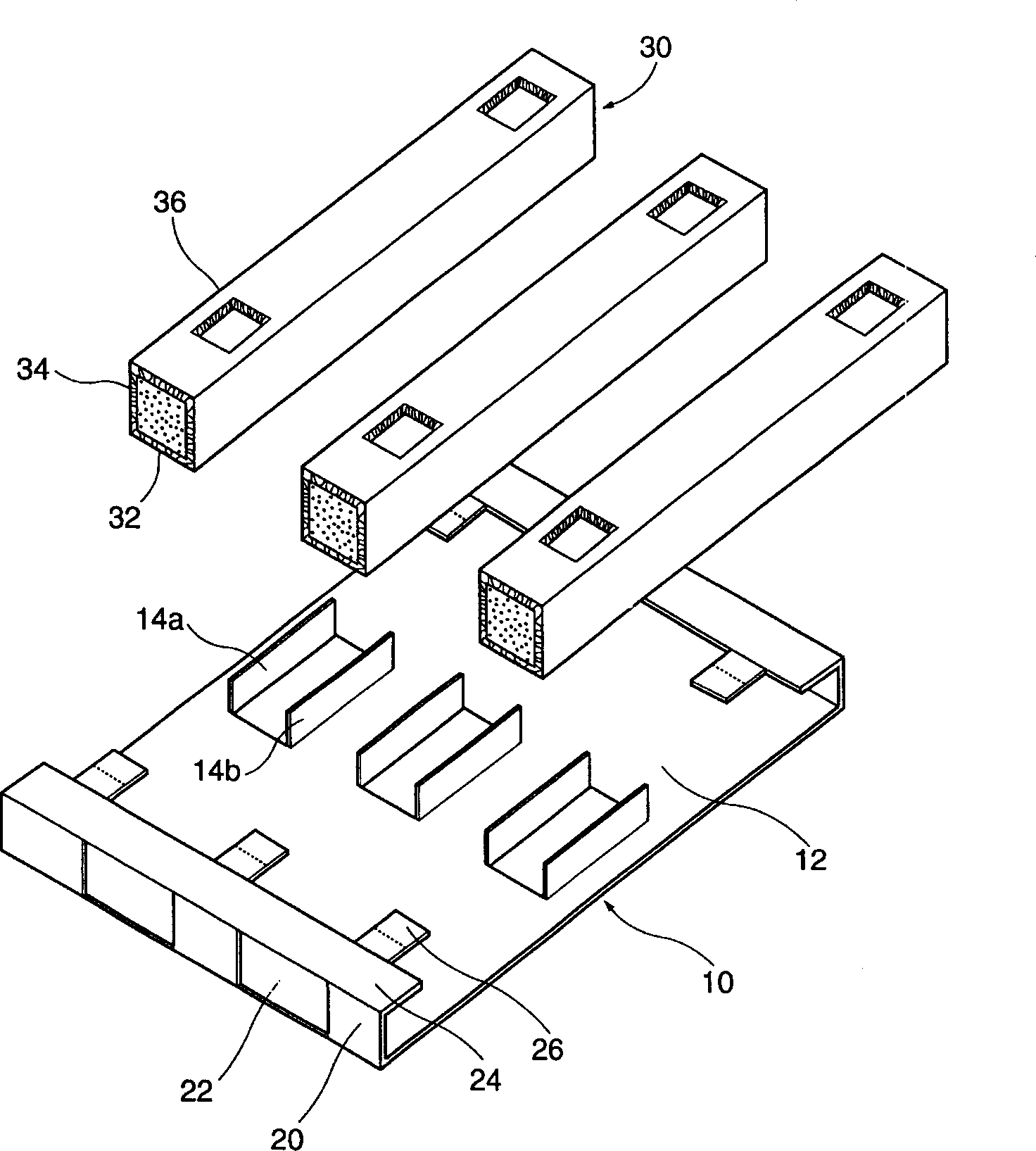

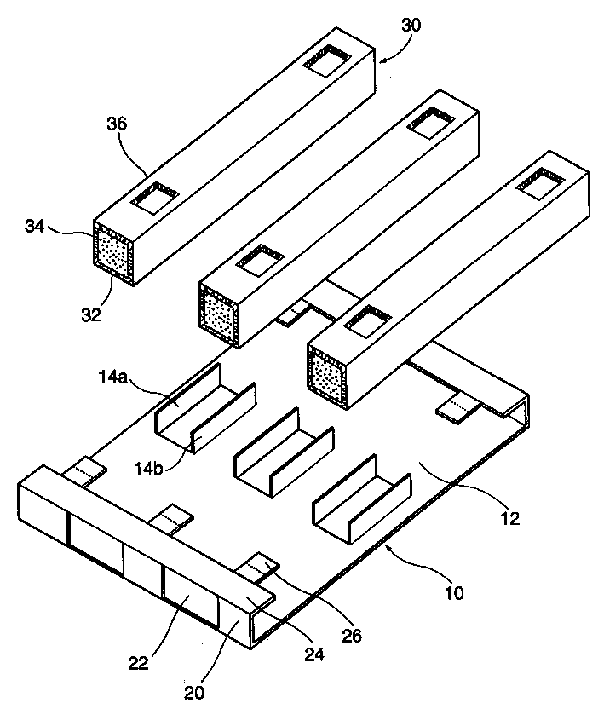

[0012] figure 1 It is a schematic plan view of the unfolded state of the lower plate on the bottom surface of the pallet of the present invention. figure 2 It is an exploded schematic view of the pallet of the present invention. refer to figure 1 , figure 2 As shown, the lower board 10 of the pallet of the present invention is made of corrugated cardboard.

[0013] The lower plate 10 has a base 12 provided with a bottom surface, and front and rear side wall portions 20 formed on the front and rear surfaces of the base. The above-mentioned base 12 is made into a bottom surface which can be used to place the intermediate supporting auxiliary material 30 as described later. The front and rear side walls 20 are formed on the base 12 in a shape extending forward and backward, and the upper part is bent and formed upright. In the middle part of above-mentioned front and rear side wall part 20, be provided with several through holes 22, so that use when the pallet that product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com