Method for mfg. hot rolled steel plate possessing superfine crystal grains and hot rolled steel plate produced

A technology of a hot-rolled steel sheet and a production method, which is applied in the field of hot-rolled steel sheet to achieve the effects of easy control, simple chemical composition and high elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

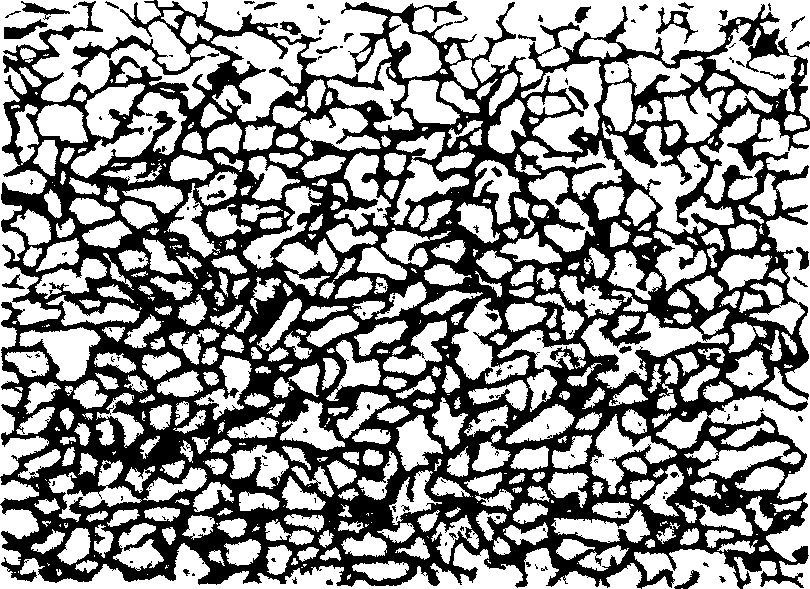

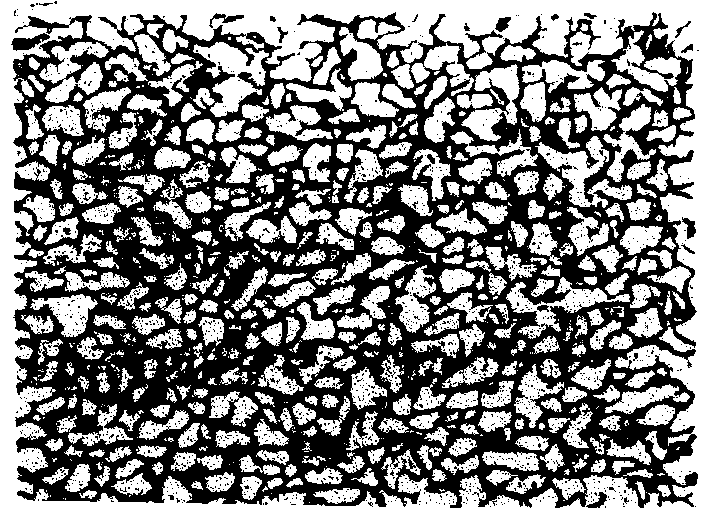

[0013] Embodiment: the production method of the hot-rolled steel plate with ultra-fine crystal grain is that carbon steel, especially the carbon steel with low carbon and low manganese content, is poured into 200 * (800~1200) * 5500mm continuous casting method with conventional continuous casting method Casting slabs, the continuous casting slabs are heated to 1200-1230°C in the heating furnace, and the heated continuous casting slabs are sent to Roll on the 1450mm hot rolling mill. Rough rolling adopts eight-pass rolling, and the rolling temperature is 950-1100°C. After the rough rolling, the intermediate slab enters the finish rolling mill for finish rolling, and the temperature at the entrance of the finish rolling mill is controlled to be 870-900°C. Finish rolling adopts six rolling passes, the reduction of the first pass of finish rolling is 13-16mm, the reduction of the second pass of finish rolling is 8-10mm, and the reduction of the third pass is 5-7mm , through the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com