Suspension type self vibration damping difference flow sensor

A flow sensor, suspended technology, applied in the field of flow sensors, can solve the problems of limited ability to resist pipeline vibration, large noise mixed in the output signal, weak anti-interference ability of flow sensors, etc., to achieve a large range, strong anti-interference, The effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

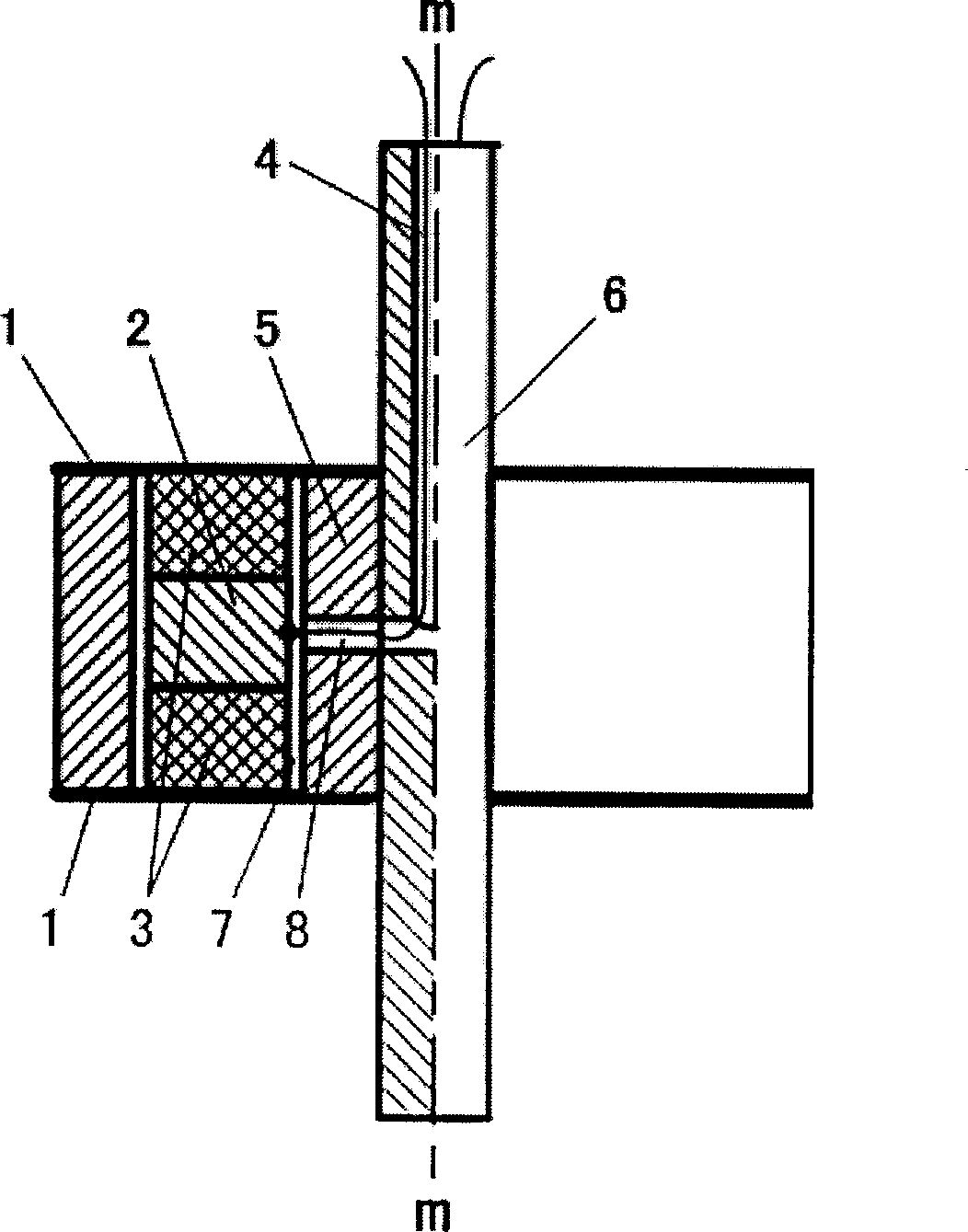

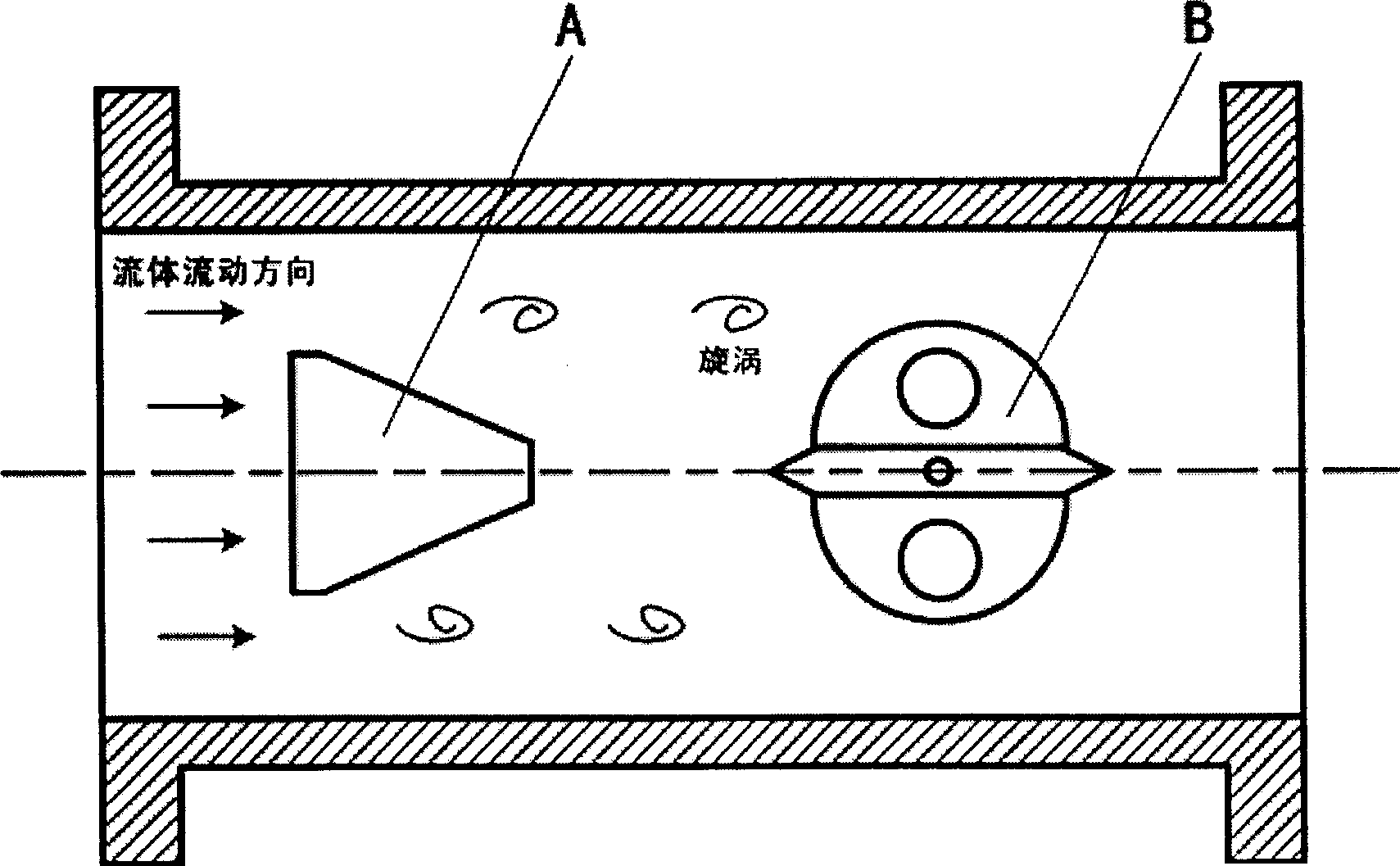

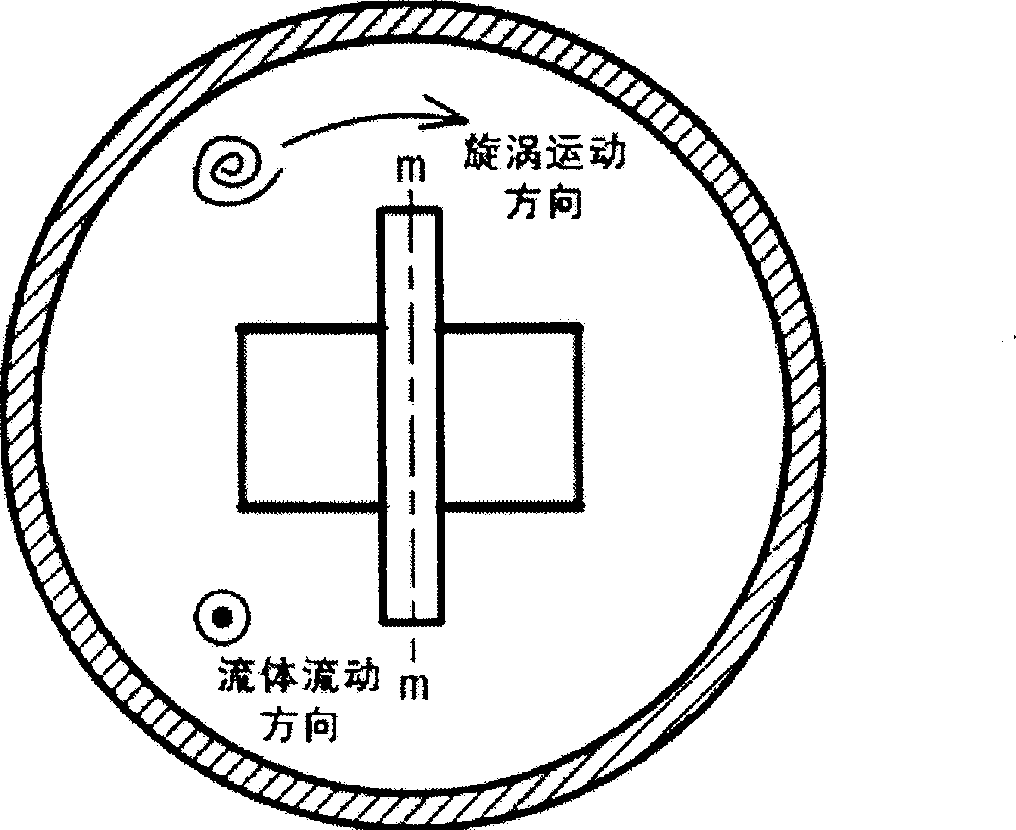

[0009] refer to figure 1 , the suspended self-damping flow sensor includes detection units symmetrically fixed on both sides of the plate 6, each detection unit includes a housing 5, in order to obtain a more stable signal, a semi-cylindrical housing is generally used, and the housing 5 has a shape parallel to the axis of the plate m-m parallel through hole 7, the through hole 7 is connected with the axial outlet hole 4 of the plate by a channel 8, the two ends of the through hole 7 are respectively sealed by elastic diaphragms 1, and there are two piezoelectric ceramic sheets 3 in the through hole , the size, mass and sensitivity coefficient of the two piezoelectric ceramic sheets are the same, one end of the two piezoelectric ceramic sheets is welded to the elastic diaphragm 1 respectively, and the other end is welded to the metal block 2 arranged between the piezoelectric ceramic sheets . In this way, the metal block 2 and the two piezoelectric ceramic sheets 3 form a rigi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com