Diffraction spectrum measurement of grating plane mirror and its applications

A measurement system and diffraction spectrum technology, applied in the use of diffractive elements to generate spectrum, absorption/scintillation/reflection spectrum, spectrum investigation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

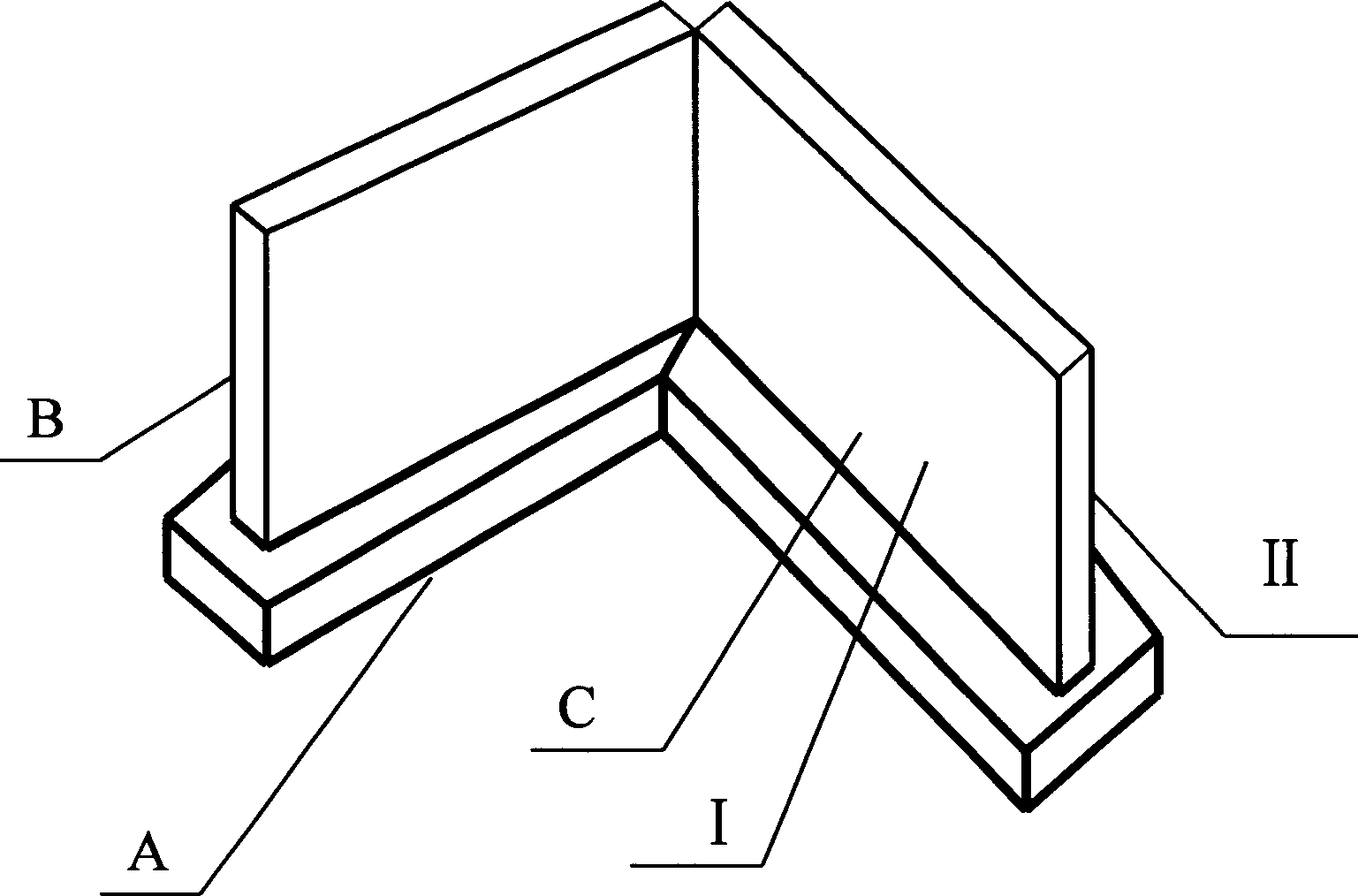

[0009] Embodiment 1: Two movable and foldable bases form a 60° horizontal support in a movable manner, the thickness of the groove is 2mm, the thickness of the double-sided reflective plane mirror B and the back coated reflective grating C are both 2mm and The thickness is the same; the two sides of the double-sided reflective plane mirror B are coated with semi-reflective film, and the back is coated with reflective grating C. It is composed of two surfaces, the grating stripe surface I and the semi-reflective surface II. There are 100 / mm transmission grating stripes, semi-reflective surface II is coated with semi-reflective light analysis film, and the light analysis film is vacuum-coated with magnesium fluoride. The ratio of the transmitted light intensity to the reflected light intensity of the semi-reflective surface II is 50:50.

[0010] The specific operation steps used are: (1) The two bases of the movable foldable horizontal bracket A are movable to form 60°, placed o...

Embodiment approach 2

[0011] Embodiment 2: Two movable and foldable bases form a 90° horizontal support A in a movable manner, the thickness of the groove is 2mm, the thickness of the double-sided reflective plane mirror B and the back coated reflective grating C are both 2mm and the thickness of the groove The thickness is the same; the two sides of the double-sided reflective plane mirror B are coated with semi-reflective film, and the back is coated with reflective grating C. It is composed of two surfaces, the grating stripe surface I and the semi-reflective surface II. There are 300 lines / mm of transmission grating stripes, the semi-reflective surface II is coated with a semi-reflective light analysis film, and the light analysis film is vacuum-plated magnesium fluoride surface, the ratio of the transmitted light intensity to the reflected light intensity of the semi-reflective surface II The specific operation steps used for 40:60 are the same as those in Embodiment 1.

Embodiment approach 3

[0012] Embodiment 3: Two movable and foldable bases form a 100° horizontal support A in a movable manner, the thickness of the groove is 2mm, the thickness of the double-sided reflective plane mirror B and the back coated reflective grating C are both 2mm and the groove The thickness of the double-sided reflective plane mirror B is coated with a semi-reflective film on both sides, and the back is coated with a reflective grating C. It is composed of two surfaces, the grating stripe surface I and the semi-reflective surface II. The grating stripe surface I adopts the holographic interference method. It is engraved with 500 / mm transmission grating stripes, semi-reflective surface II is coated with semi-reflective light analysis film, and the light analysis film is coated with silicon dioxide by hydrolysis method, the transmitted light intensity and reflected light intensity of semi-reflective surface II The ratio is 60:40, and the specific operation steps used are the same as tho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com