Method and device for measuring discharge cavity and gas gap breakdown threshold based on it

A gas gap and measuring device technology, applied in the direction of testing dielectric strength, etc., can solve the problems of electron number measurement errors, experimental inequalities, and influence on electronic development, etc., to achieve easy gap distance, accurate electron number, and wide working range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

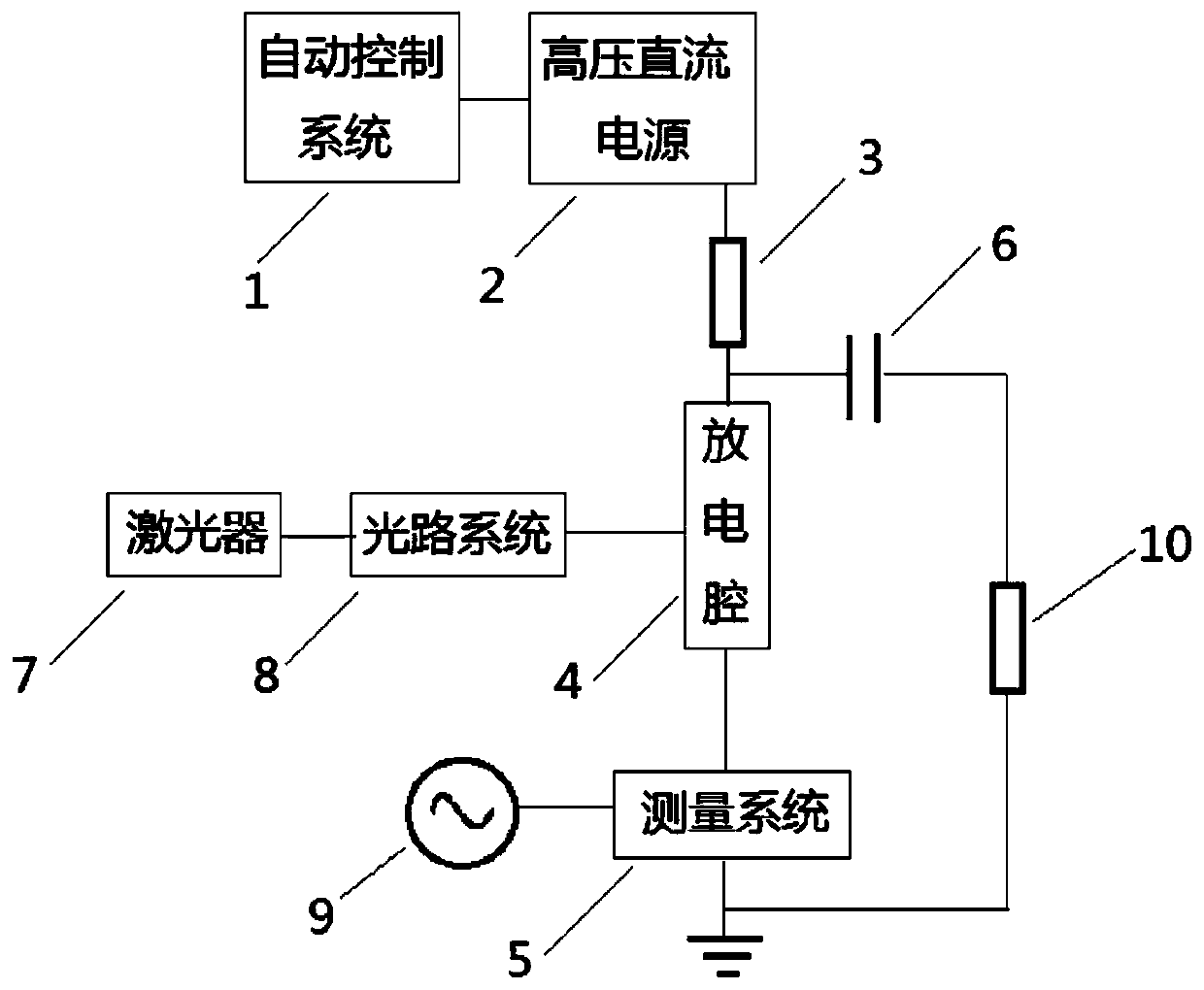

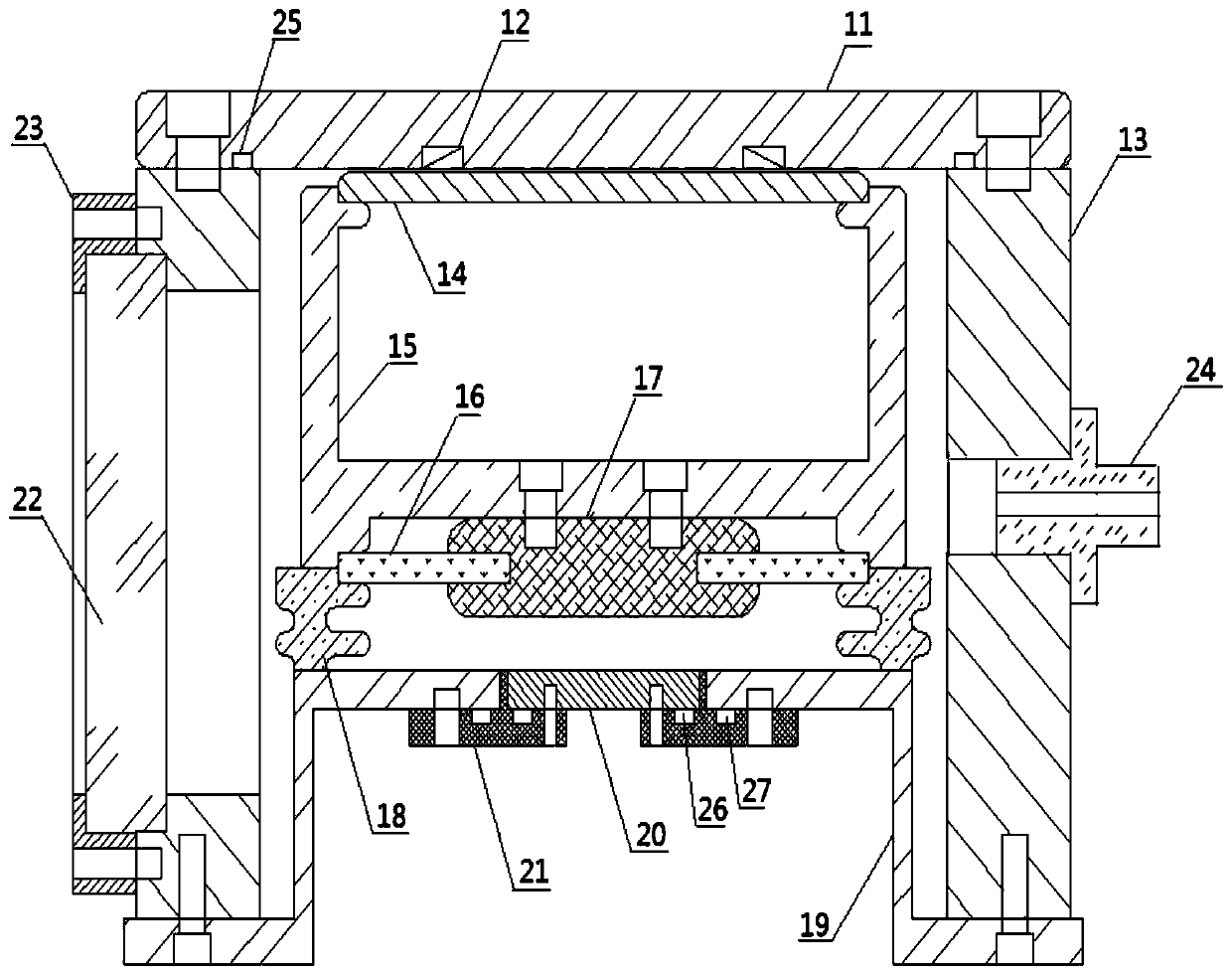

[0042] like figure 1 As shown, the device of the present invention includes a high-voltage DC power supply 2 and its automatic control system 1 , protection resistor 3 , discharge chamber 4 , measurement system 5 , charging capacitor 6 , laser 7 , optical system 8 , oscilloscope 9 and loop resistor 10 .

[0043] The automatic control system 1 includes an industrial computer and a PLC controller, the output end of which is connected to the input end of the high-voltage DC power supply 2 through a communication cable, and is used to control the switching of the DC power supply and adjust the output voltage amplitude. The high-voltage DC power supply 2 is used to generate a high DC voltage. In a preferr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com