Bamboo board producing process

A manufacturing method and board technology, which can be used in the joining of wooden veneers, manufacturing tools, wood processing appliances, etc., and can solve problems such as unusability, instability, and uneven bamboo pieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

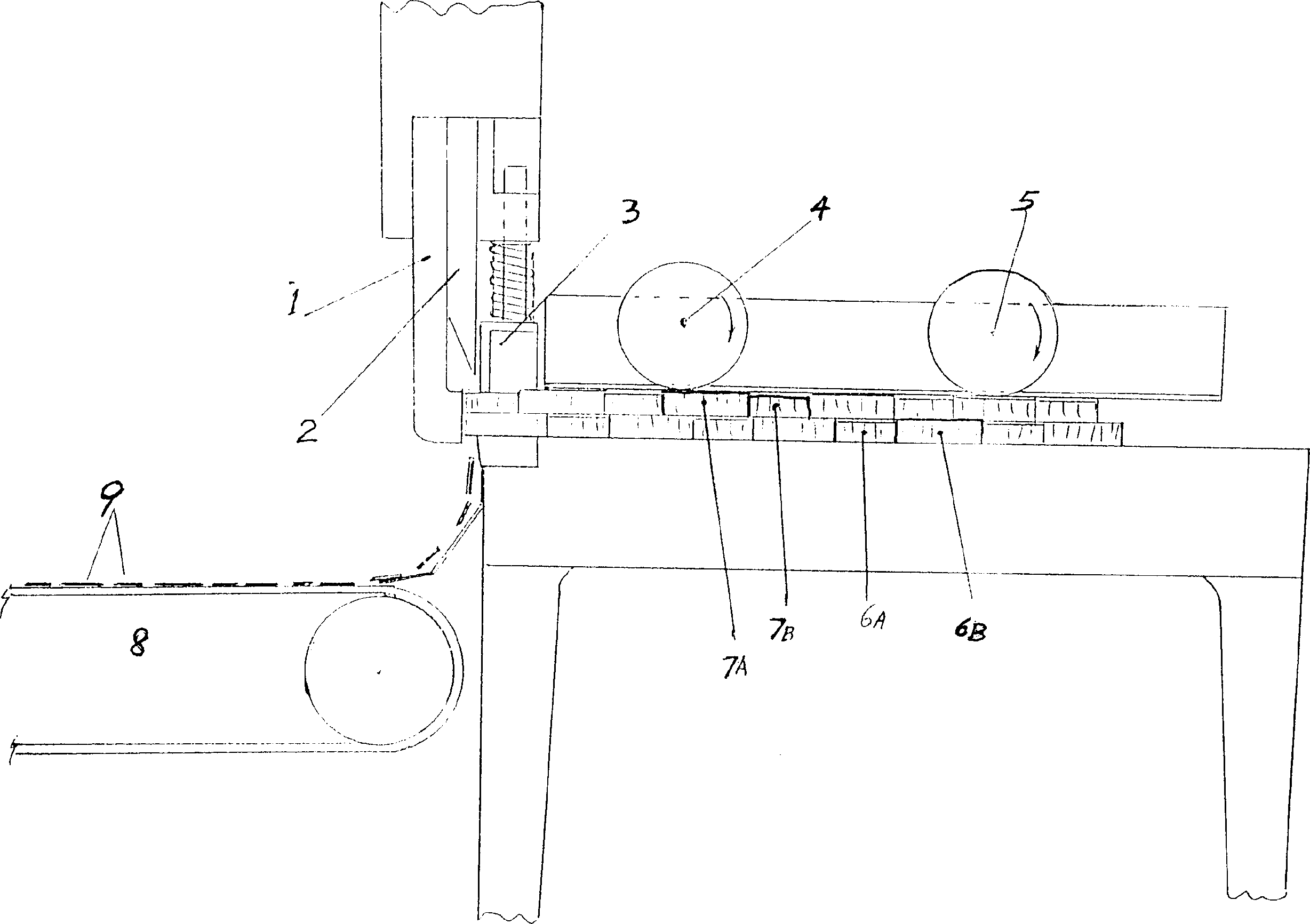

[0010] A method for manufacturing bamboo boards, comprising:

[0011] (1) bamboo is cut into sections;

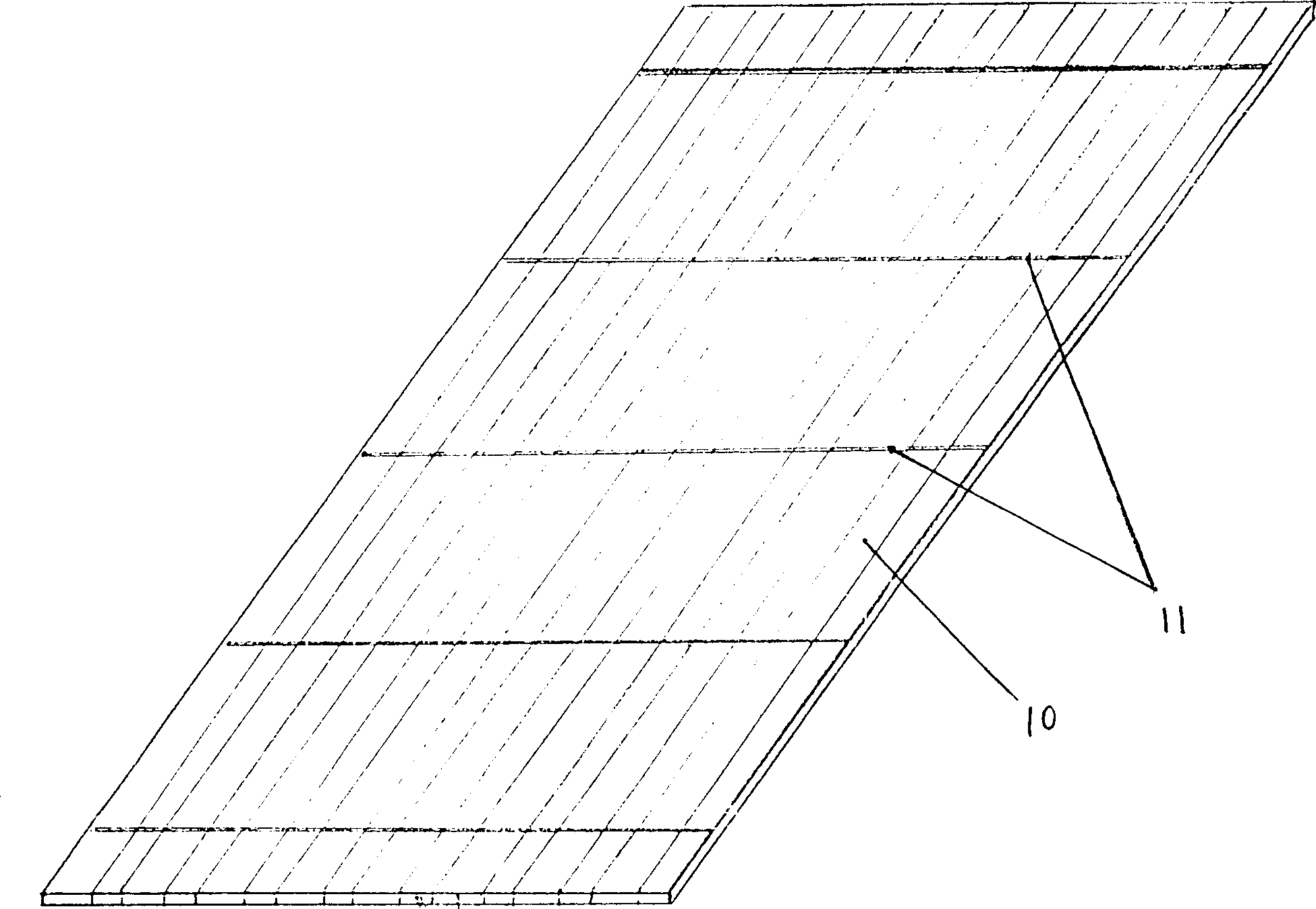

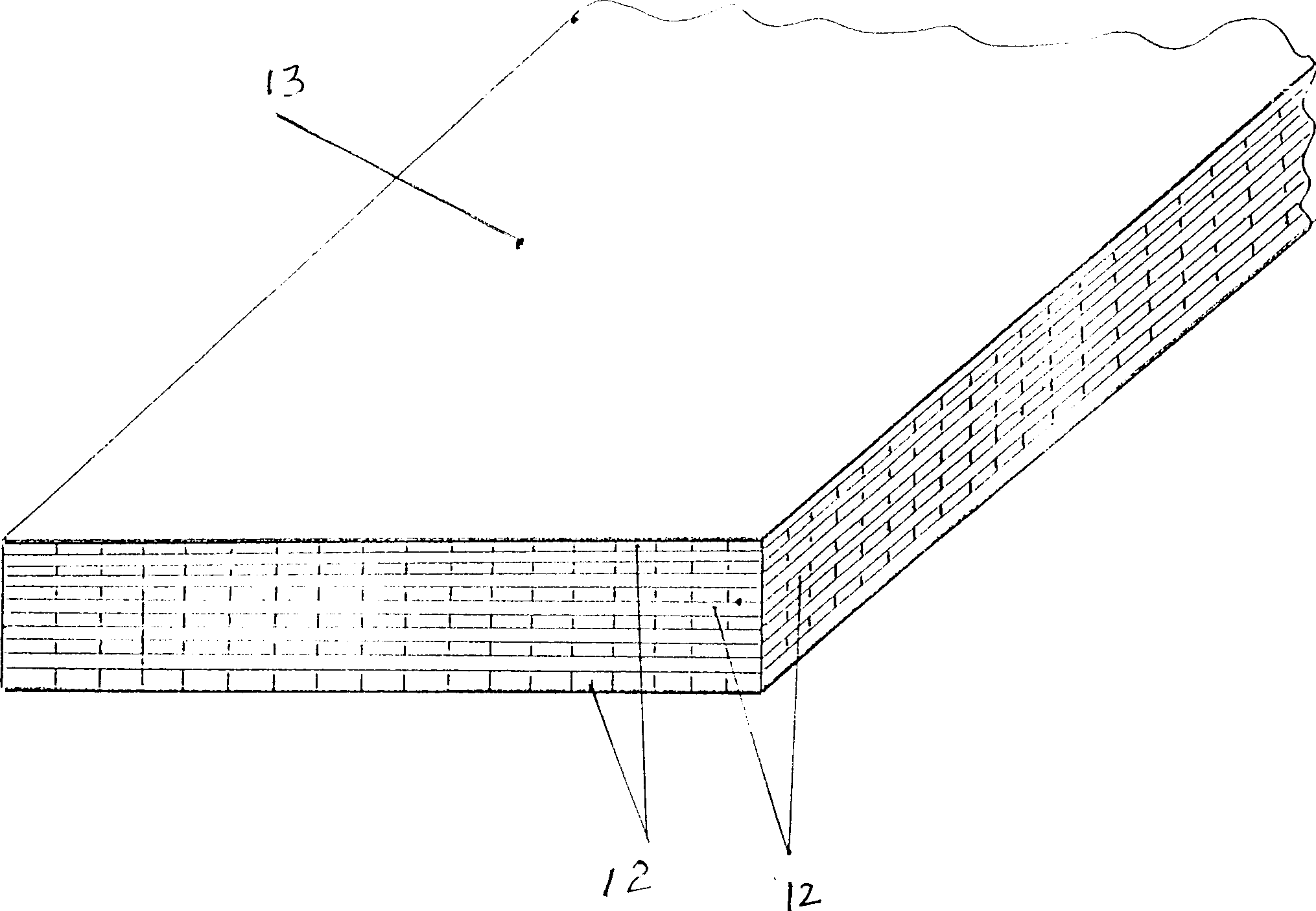

[0012] (2) Take the center of the bamboo tube as the center of the circle to form bamboo strips by radially cutting them; through removing cyanine and yellowing planing, the shearing feature is to cut through the cross-section of its thickness according to the length direction of the bamboo strips, and its width of the formed bamboo strips is equal to that of the bamboo strips. The thickness of the cut bamboo strips has different widths at the left and right ends, and its structure includes the fiber characteristics from the inside to the outside; the bamboo strips can also be pre-planed into shapes of equal width and thickness before slicing. roughly the same degree.

[0013] (3) The shearing method of the above (2) is characterized in that two layers of materials are stacked, and the bamboo strips are respectively composed of up, down, left, right, wide, thick, narrow, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap