Reluctance sensor

A magneto-resistive sensor and magneto-resistive technology, which is applied in the fields of magnetic field-controlled resistors, instruments, nano-magnetism, etc., can solve the problem that the characteristic curve performance deviates from linearity, and achieves the reduction of hysteresis, noise reduction, Effects of Large Linear Regions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

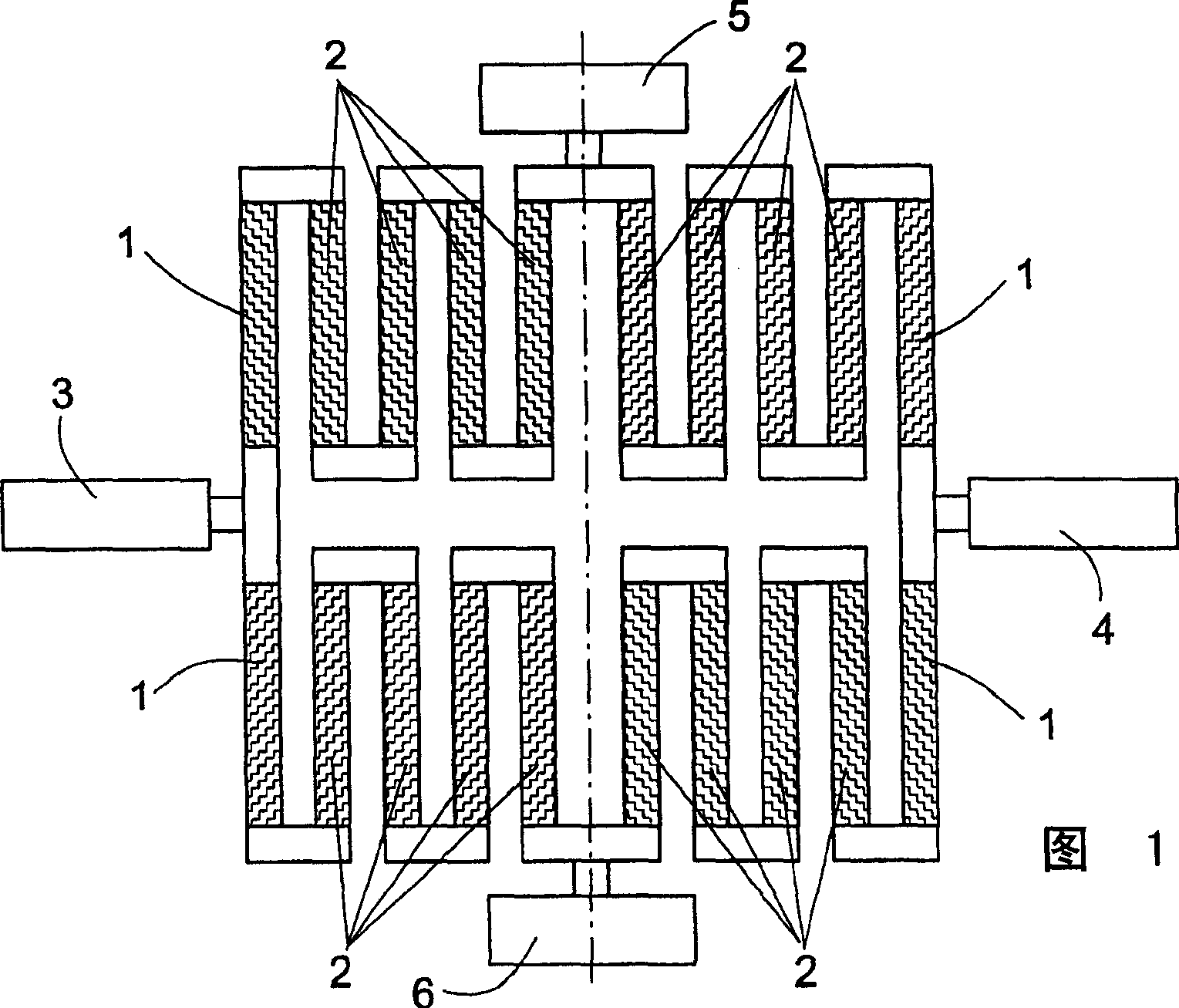

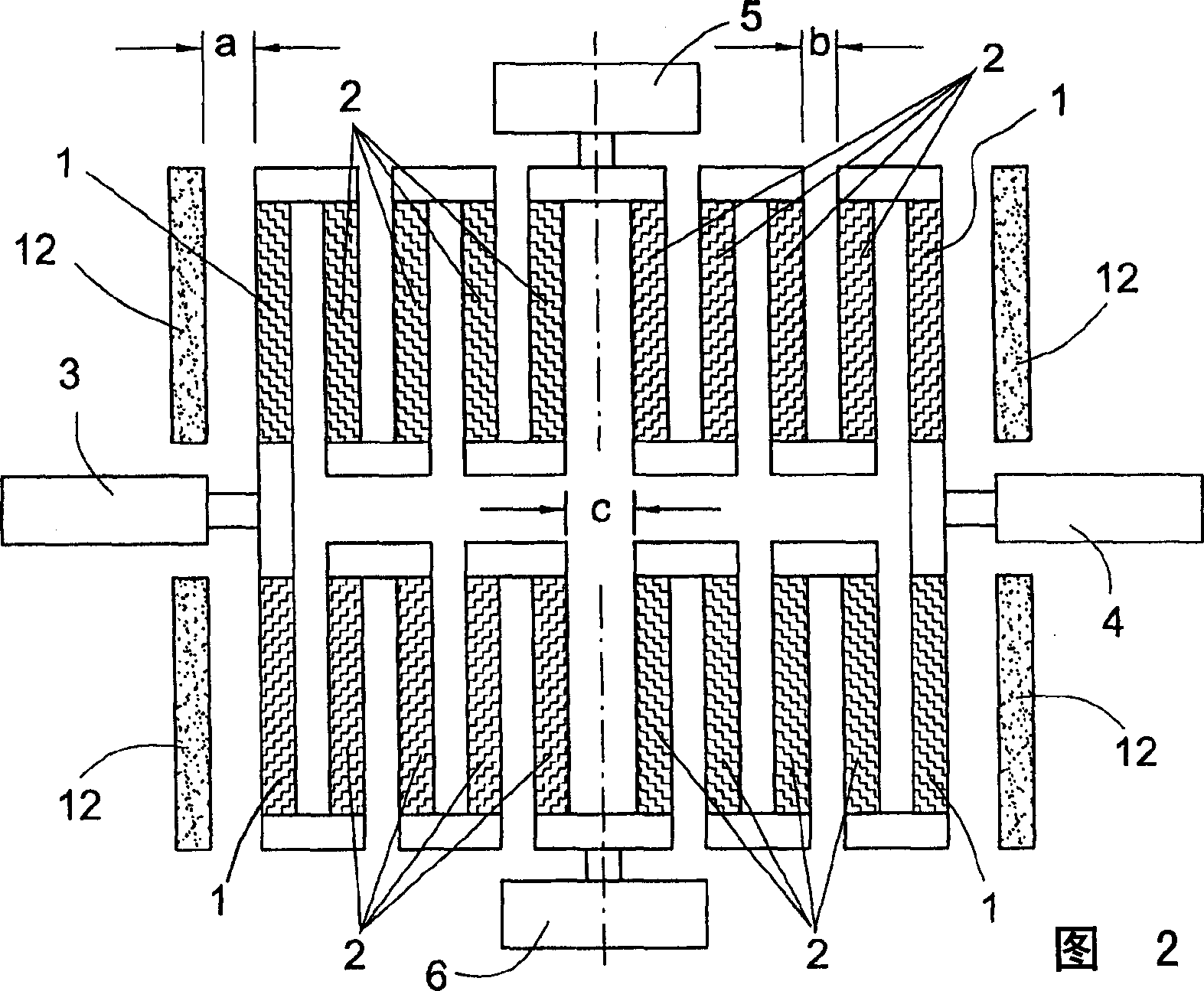

[0038] FIG. 1 shows the schematic structure of a known type of magnetoresistive sensor viewed in the plane of its conductor structure. The sensor comprises an arrangement of a plurality of strip-shaped conductors 1, 2 formed of magnetoresistive material and extending substantially parallel to each other in two rows, the boundary conductors of which are provided with reference numeral 1 forming the border of the conductor arrangement and are therefore described as peripheral strips, Whereas the other conductors provided with reference numeral 2 are bounded on all sides by at least a further conductor 1 or 2 which is considered to extend "inside" the conductor arrangement and is therefore referred to below as an inner conductor. The four adjacent conductors of the inner conductor 2 in each case and the peripheral strip 1 adjacent to it in each row of conductors are electrically connected to each other in the illustrated embodiment and represent the branches of a circuit formed as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com