Central screw type soil pressure balance miniature push bench

A technology of earth pressure balance and pipe jacking machine, which is applied in the direction of mechanical equipment, pipeline laying and maintenance, pipes/pipe joints/fittings, etc. It can solve the problems of pipeline influence and the inability to correctly control the pipeline direction, etc., and achieve a short construction period , Easy to manufacture and promote application, and the effect of light construction equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

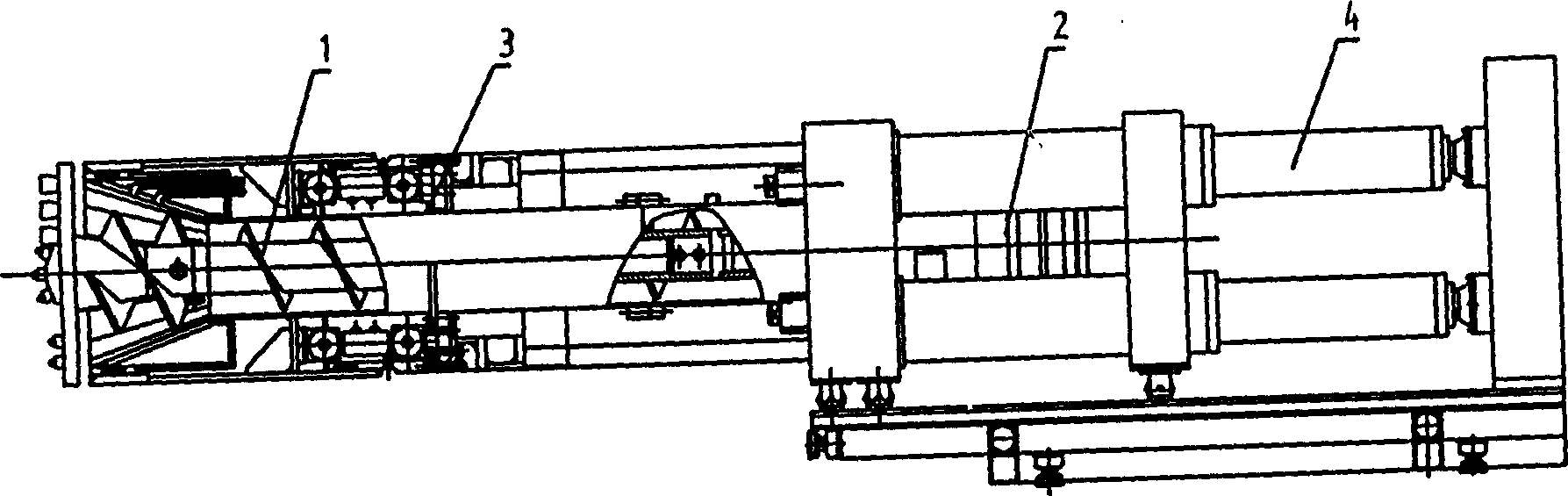

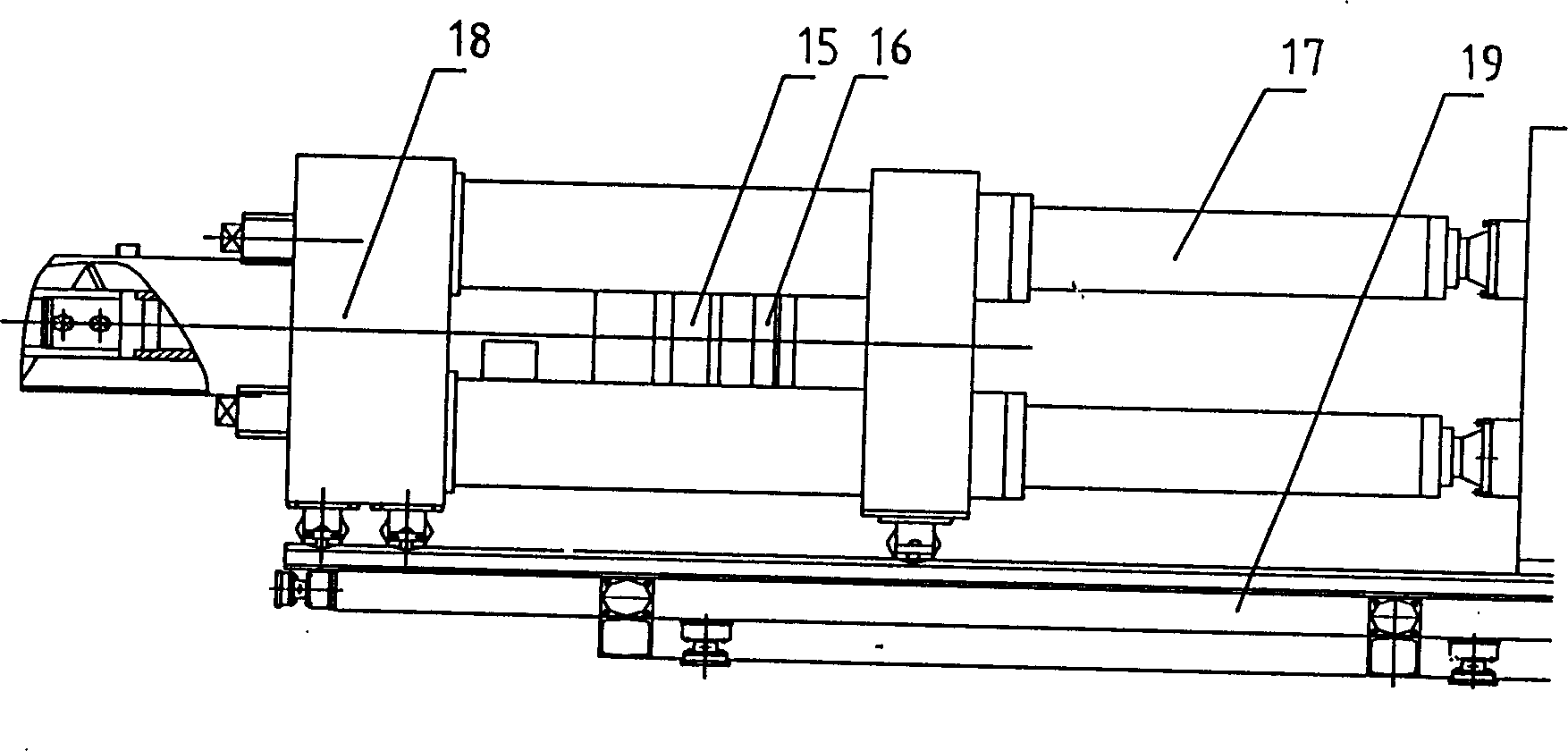

[0019] like figure 1 As shown, the present invention mainly includes: a pipe jacking machine host 1, a cutter head drive system 2, an axis monitoring system 3, and a main jacking device 4. The pipe jacking machine host 1 is located at the forefront as a main cutting device, and it is conveyed The shaft is connected with the drive shaft of the cutterhead drive system 2 with a pin. The cutterhead drive system 2 is installed in the working well, in the middle of the main jacking device 4. The main jacking device 4 is located on the track of the base at the back side of the working well. The axis monitoring system 3 installed in the pipe jacking machine host 1.

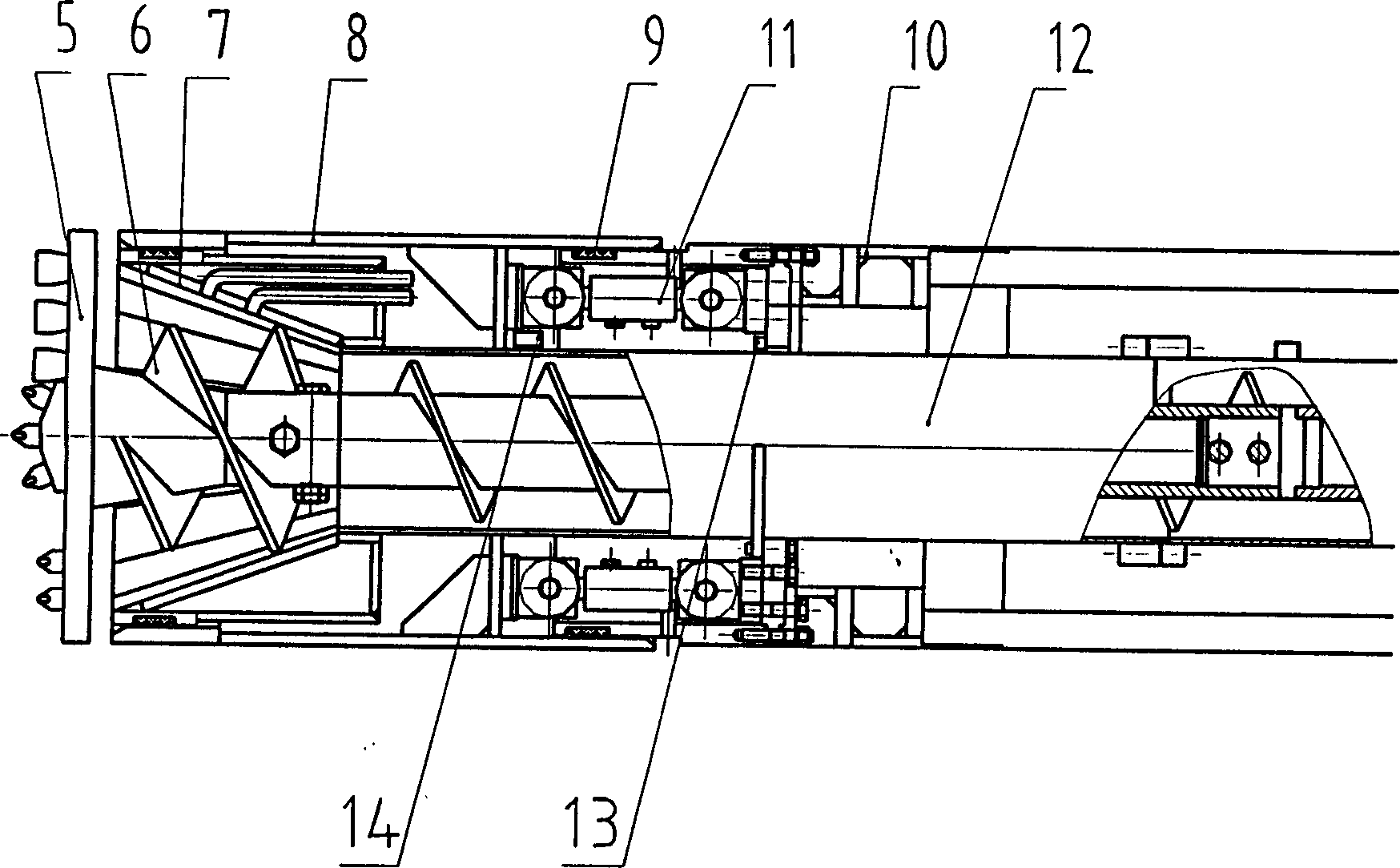

[0020] like figure 2 As shown: the main engine 1 of the pipe jacking machine includes: a large cutterhead 5, a central stirring body 6, a central cone 7, a front body 8, a sealing device 9, a rear casing 10, an ultra-high pressure correction cylinder 11, and a central screw conveyor 12, Its connection method is: the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com