Fluid machinery with high pressure and lower pressure sectors

A technology of fluid machinery and fluid medium, applied in mechanical equipment, liquid fuel engines, components of pumping devices for elastic fluids, etc., can solve the distortion and deformation of the outer shell, uneven heating of the outer shell, and scraping of the outer shell by blades, etc. problems, to achieve the effect of small mass, saving materials and time, improving starting characteristics and running characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

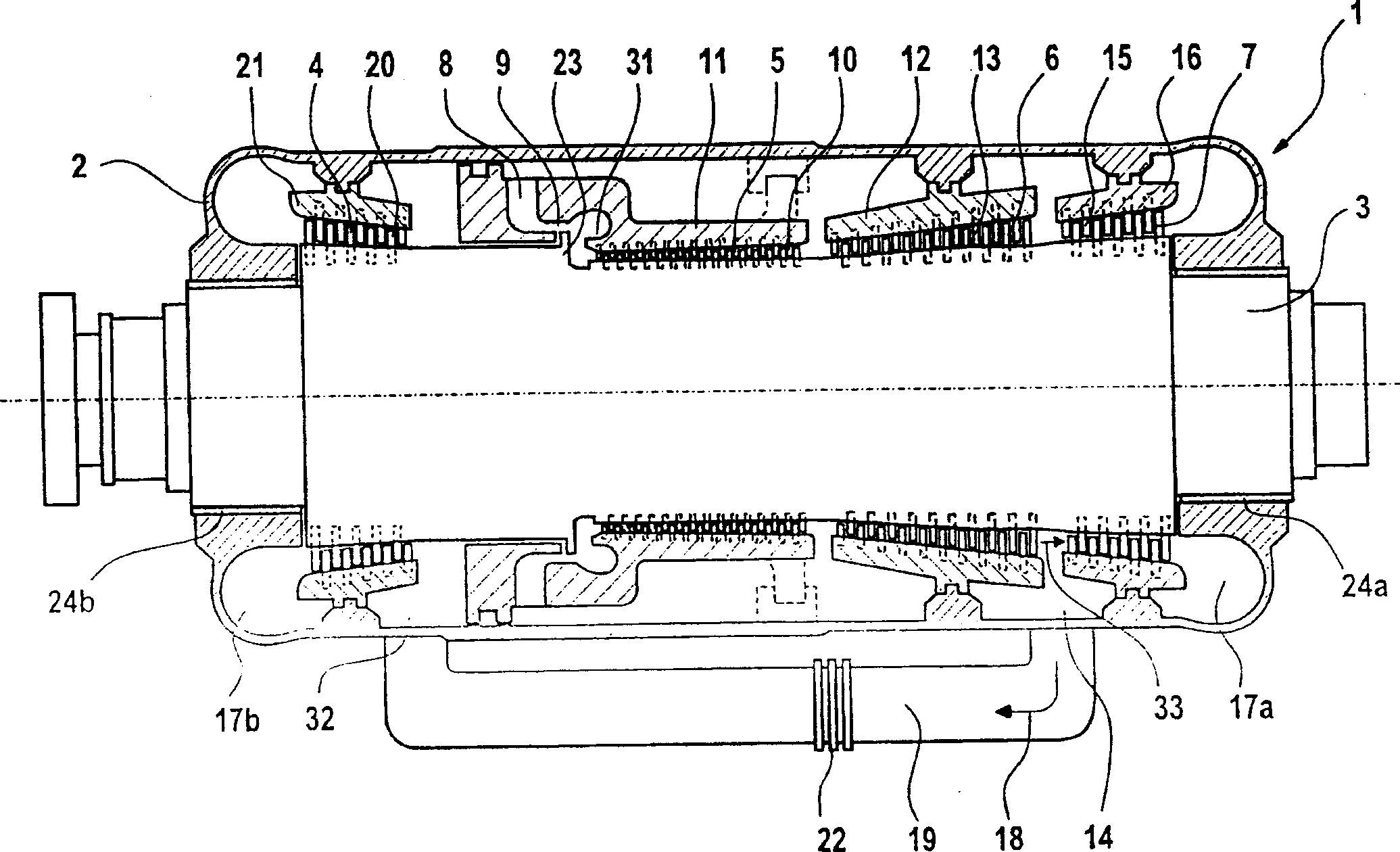

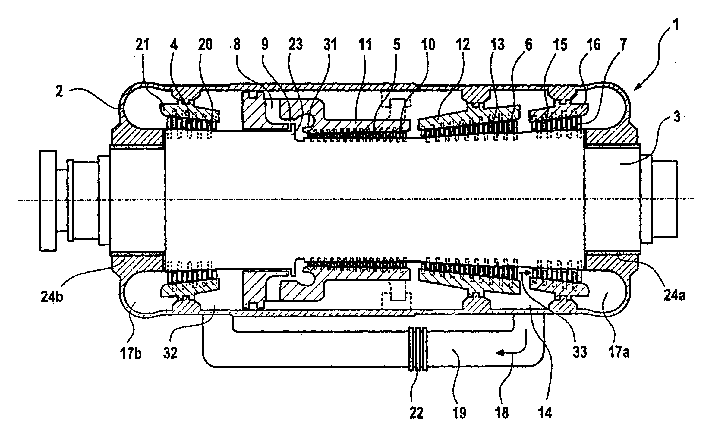

[0023] figure 1 It is a simplified longitudinal sectional view of a fluid machine 1 . The fluid machine has an outer casing 2 , several inner casings 11 , 12 , 16 , 21 and a rotor 3 . Four blade regions 4 , 5 , 6 , 7 are provided on the rotor 3 . These four blade areas are divided in the present embodiment into two inner blade areas 5 , 6 and two outer blade areas 4 , 7 . The two outer blade regions 4 , 7 are arranged opposite each other and point away from the inner blade region 5 , 6 respectively. An inlet opening 8 is contained in the outer casing upstream of the first inner vane region 5 . A control stage 9 is arranged starting from the inlet opening 8 towards the first inner vane region 5 . After the adjustment stage 9 there is also an expansion section 31 towards the first inner blade region 5 . In the illustrated embodiment, guide vanes 10 are arranged on the inner housing 11 in the first inner vane region 5 . Following the first inner blade region 5 is a further ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com