A 3D printing method for large area and large thickness nylon material structure

A 3D printing and material structure technology, applied in the field of 3D printing, can solve the problems of poor quality stability, uneven heating, gaps, air bubbles and other problems of nylon products, so as to improve the efficiency of molding operations and processing accuracy, and improve the compactness and structural uniformity , Improve the effect of reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

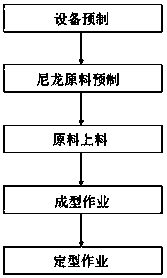

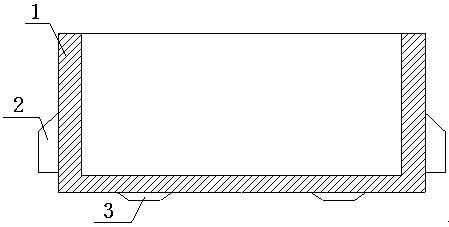

[0022] Such as figure 1 As shown, a large-area and large-thickness nylon material structure 3D printing method includes the following steps:

[0023] The first step is equipment prefabrication. Firstly, the forming tray is installed on the 3D printing equipment supporting platform, and the midpoint of the imaging tray corresponds to the origin position of the 3D printing equipment workbench, and then at least two heating devices are evenly distributed on the outer surface of the forming tray. Then adjust the heating device of the 3D printing equipment to the level, and adjust the printing nozzle of the 3D printing equipment to be directly above the origin of the workbench of the 3D printing equipment, and the distance between the upper surface of the forming tray and the upper surface of the forming tray is 1.5 mm as the distance between the printing nozzle and the printing working surface Job gap, and then positioned for standby;

[0024] The second step is the prefabricatio...

Embodiment 2

[0033] Such as figure 1 As shown, a large-area and large-thickness nylon material structure 3D printing method includes the following steps:

[0034] The first step is equipment prefabrication. Firstly, the forming tray is installed on the 3D printing equipment supporting platform, and the midpoint of the imaging tray corresponds to the origin position of the 3D printing equipment workbench, and then at least two heating devices are evenly distributed on the outer surface of the forming tray. Then adjust the heating device of the 3D printing equipment to the level, and adjust the printing nozzle of the 3D printing equipment to be directly above the origin of the workbench of the 3D printing equipment, and the distance between the upper surface of the forming tray and the upper surface of the forming tray is 1mm as the distance between the printing nozzle and the printing working surface Job gap, and then positioned for standby;

[0035] The second step is the prefabrication o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com