Device for sintering shaped body

A technology of forming body and driving device, which is applied in glass forming, furnace type, lighting and heating equipment, etc., can solve problems such as non-allowance, and achieve the effect of eliminating damage and uneven heating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

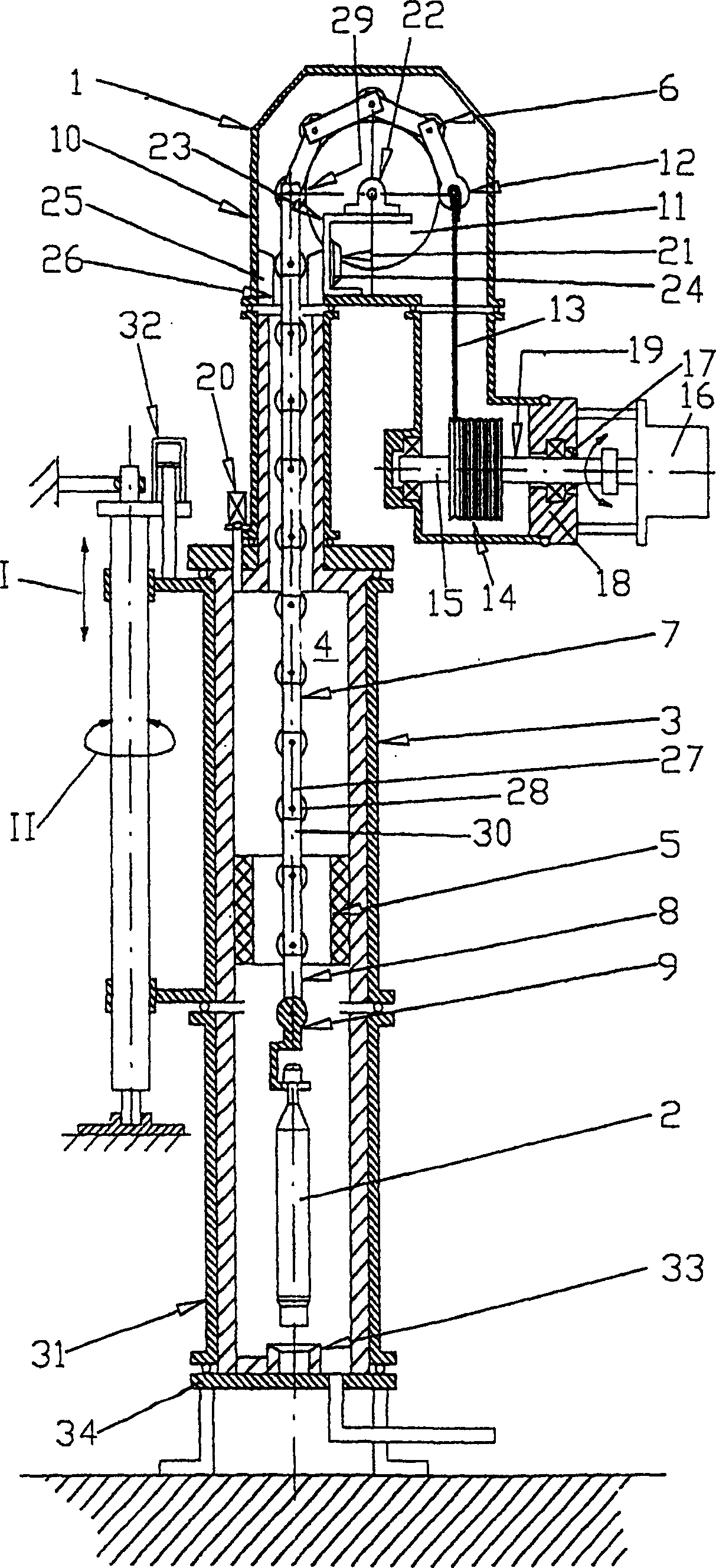

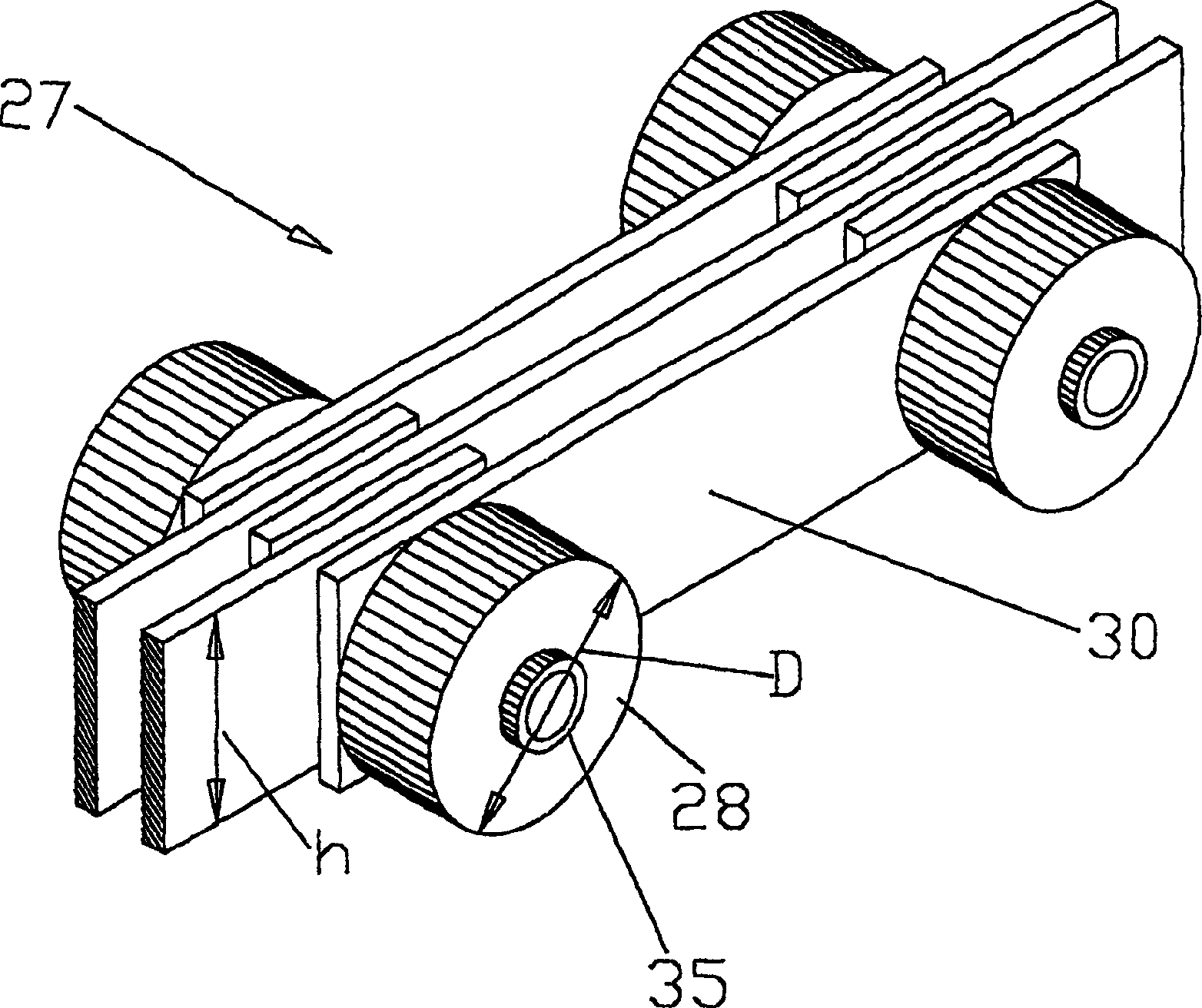

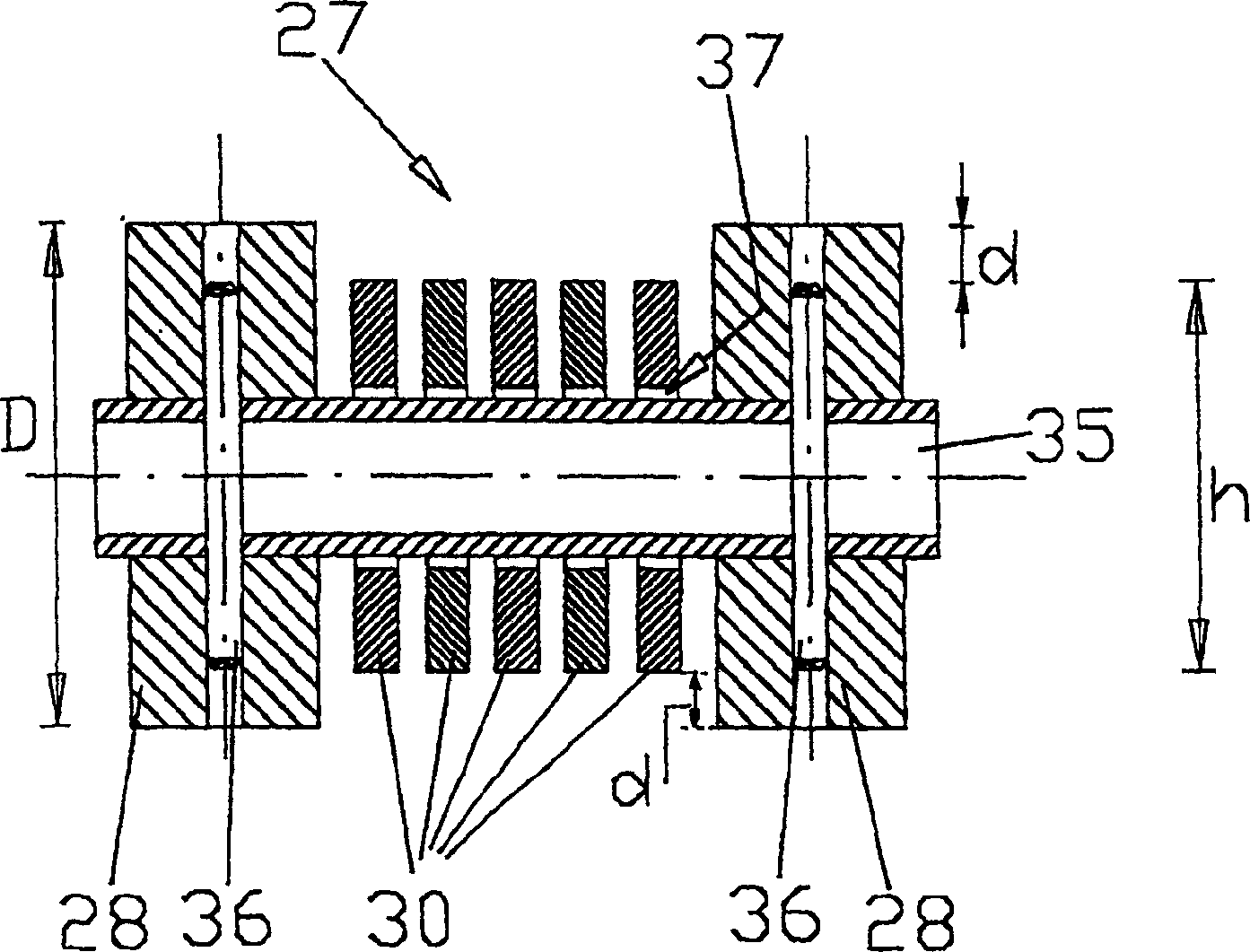

[0036] figure 1 A sintering device 1 according to the invention for sintering porous shaped bodies 2 is shown in cross section. As a basic component, the device 1 comprises a gas-tight chamber 3 , in an interior 4 of the gas-tight chamber 3 , the shaped bodies 2 can be conveyed vertically in succession to a heating zone 5 . This is achieved by means of a lifting mechanism 6 with a chain 7 , the lower end 8 of which has a support 9 for the shaped body 2 . In the region of the upper kettle 10 of the airtight chamber 3 , the course of the chain 7 is reversed by deflection wheels 11 , and the free end 12 of the chain 7 opposite the molded body 2 is equipped with a traction rope 13 . The traction rope 13 can easily be wound up on the take-up mechanism 14 in the form of a reel, thus allowing the required lifting movement of the shaped body 2 . The reel 14 is connected to the drive shaft 15 through a flange, and the drive shaft is directly connected to the drive device 116 arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com