Precisively positioning mechanism without interferes in multiposition process system

A processing system and precise positioning technology, applied in metal processing, mechanical equipment, belts/chains/gears, etc., can solve problems such as cost increase, and achieve the effect of reducing volume, good economy and low precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

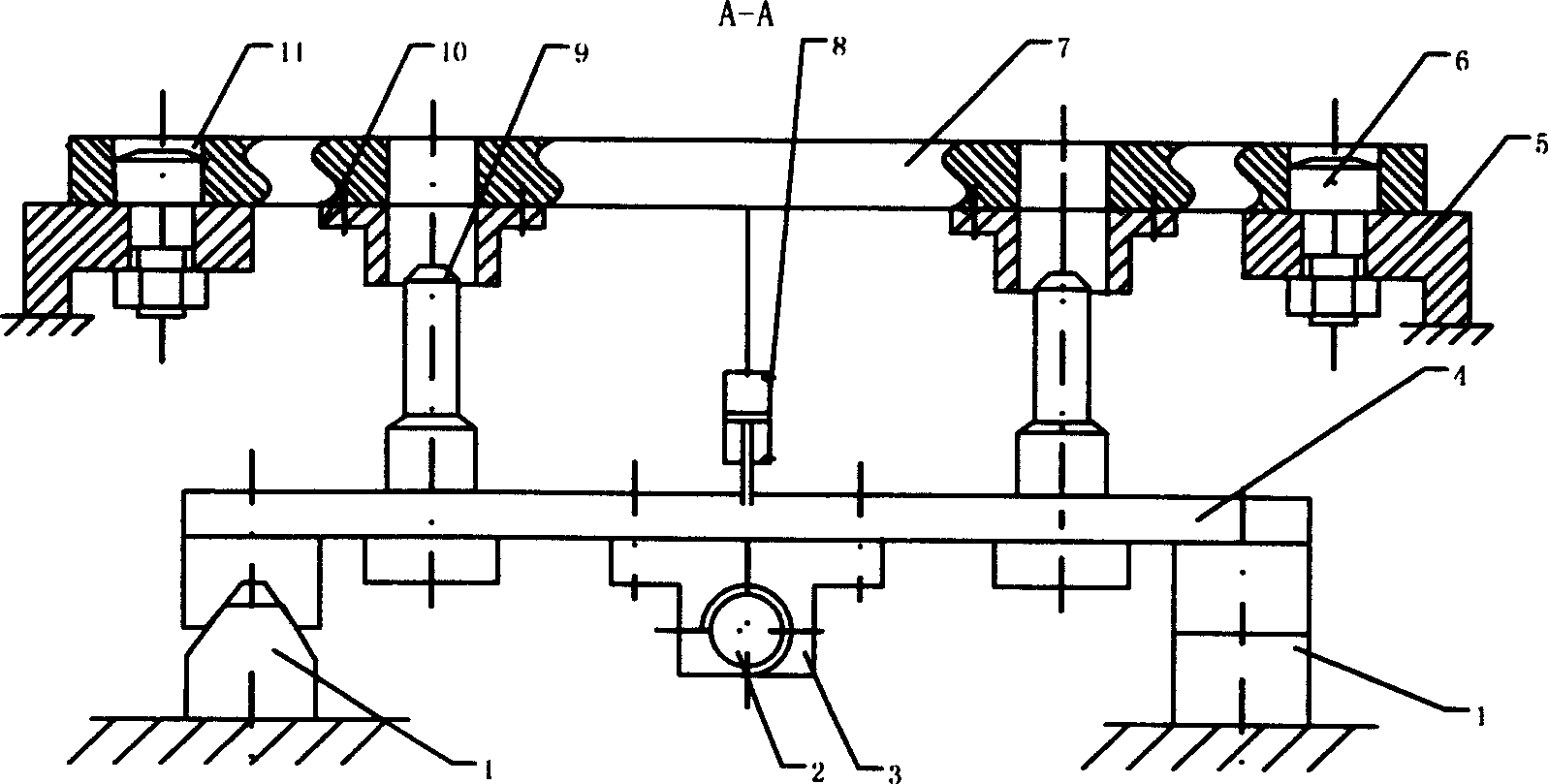

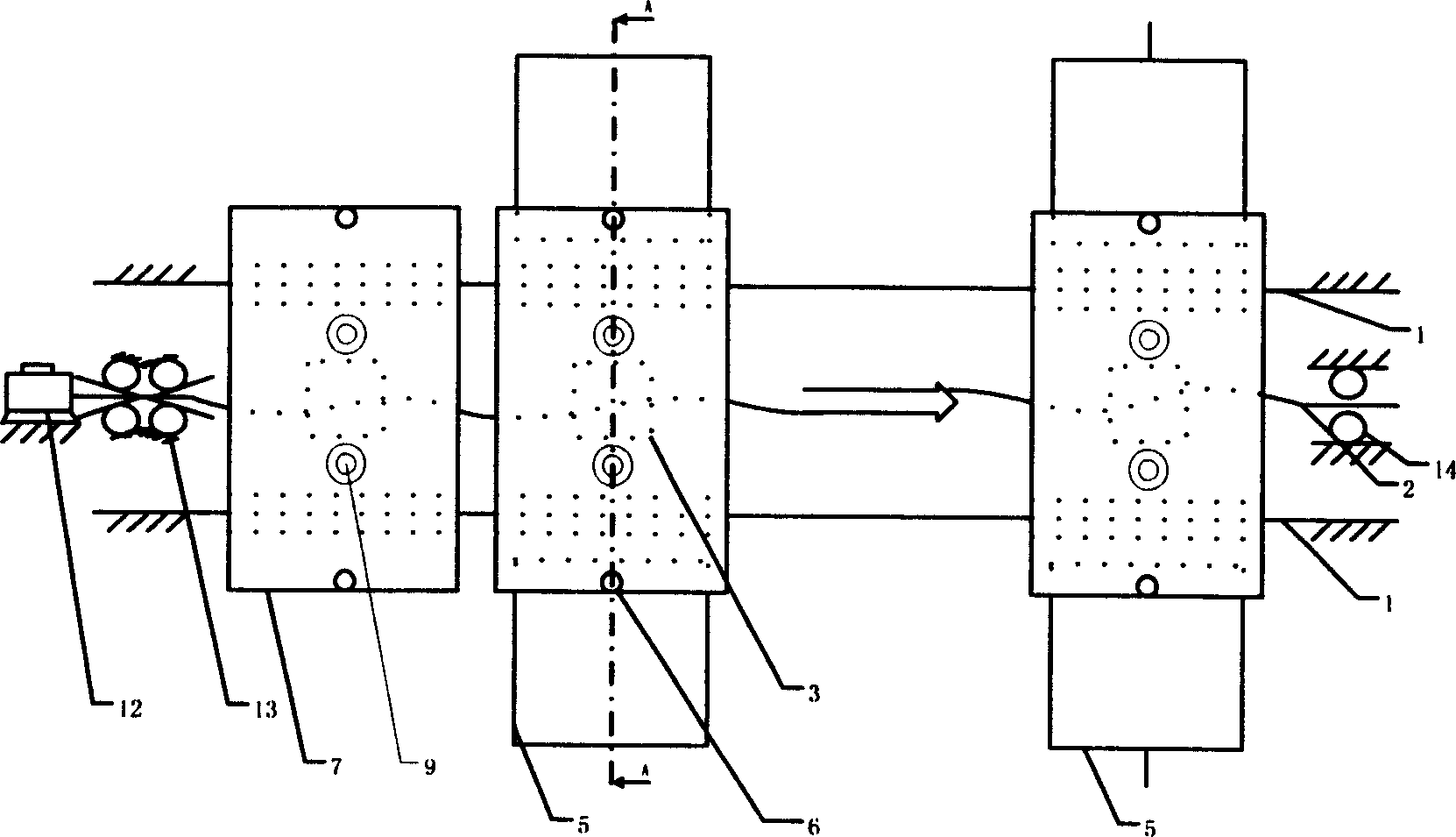

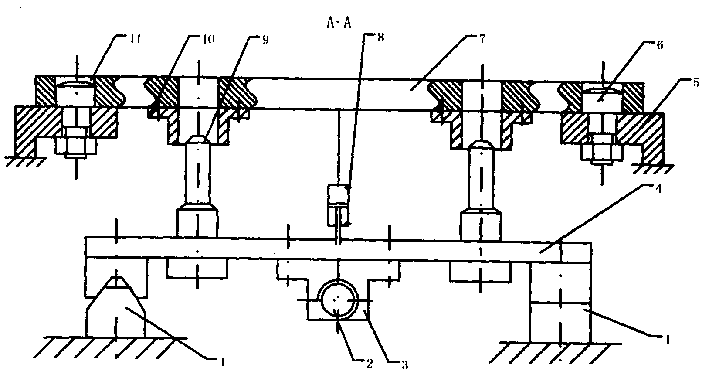

[0017] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0018] The structure of the present invention is as figure 1 , 2 shown. The two ends of accompanying platform 4 are placed on guide rail 1, and accompanying platform 4 can move on guide rail 1. The nut 3 is located in the middle of the bottom surface of the accompanying platform 4, and is fixedly connected with the accompanying platform 4. The screw mandrel 2 is placed in the middle of the two guide rails 1 and is parallel to the guide rails 1 . Both ends of the screw mandrel 2 are respectively positioned by a double-row radial thrust bearing 13 and a deep groove ball bearing 14 , and driven to rotate by a motor 12 . The screw mandrel 2 and the nut 3 form a helical motion pair, and when the screw mandrel 2 rotates, the nut 3 is driven so that the accompanying table 4 moves on the guide rail 1 . The special positioning cylindrical pin 9 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com