Film forming device and method, producing device and method for liquid-crystal device

A technology of liquid crystal devices and thin films, which is applied in the direction of spraying devices, liquid spraying devices, and devices for coating liquid on the surface, etc., which can solve problems such as waste, uneven film thickness, and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, the present invention will be explained in detail.

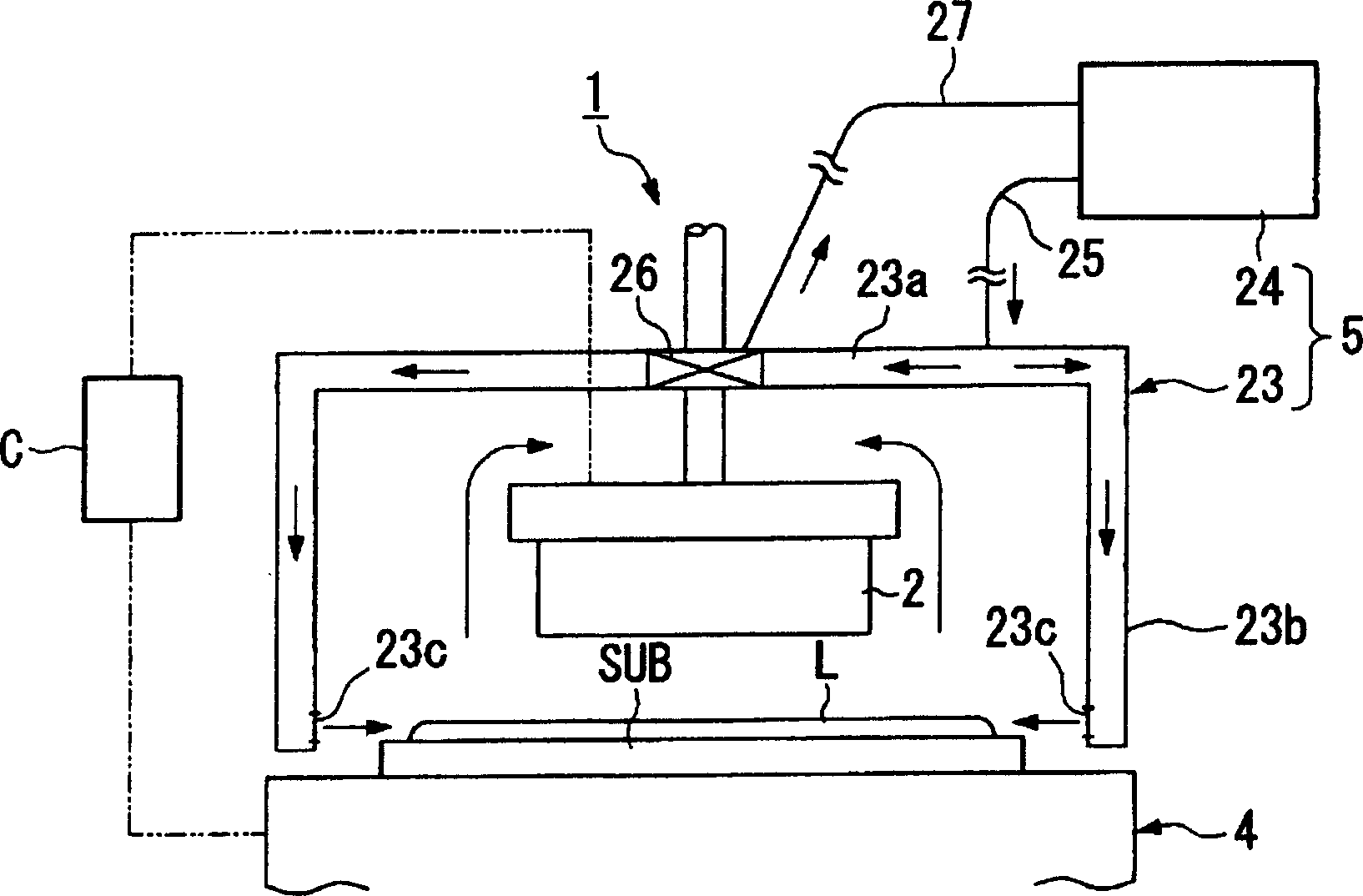

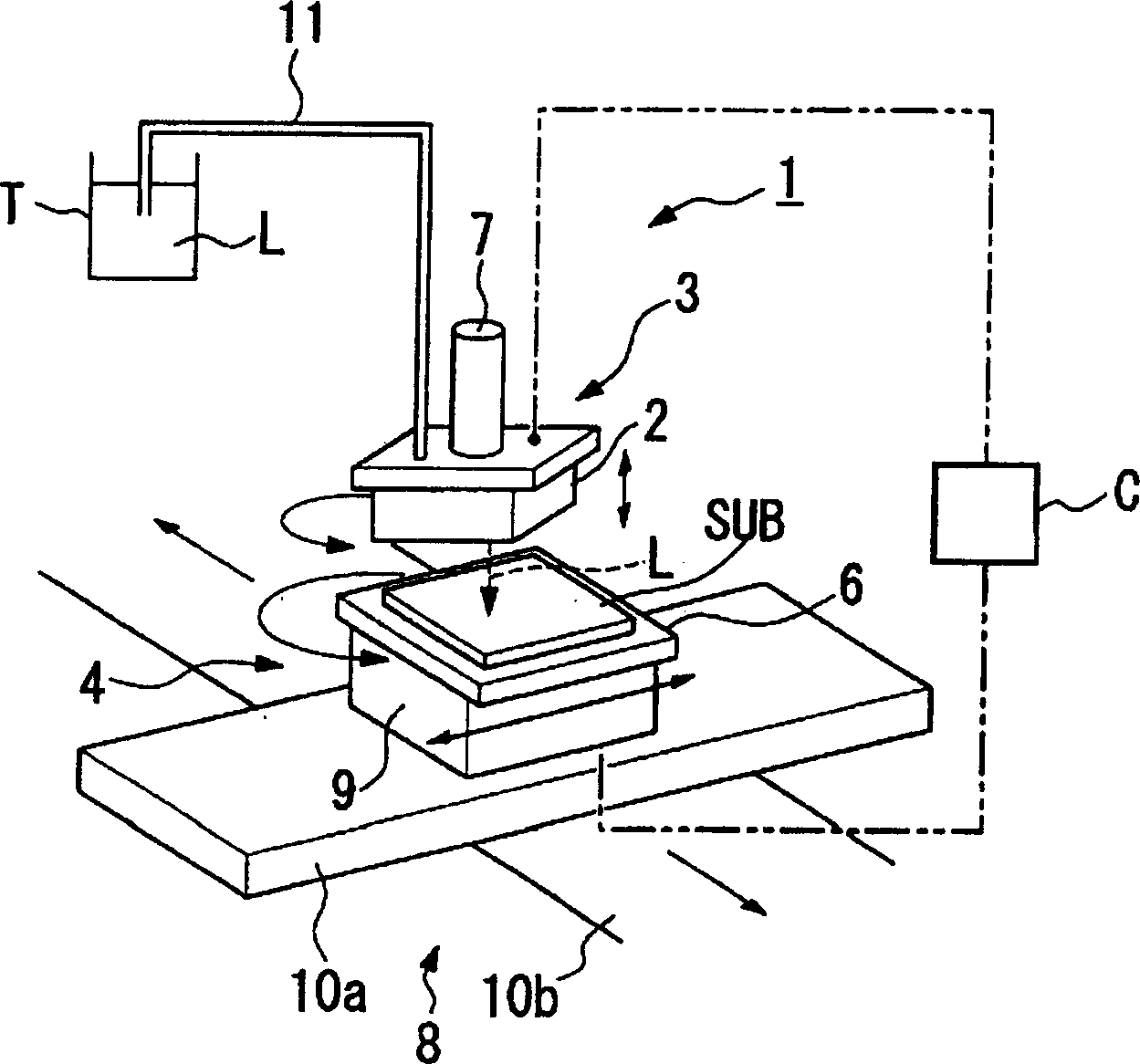

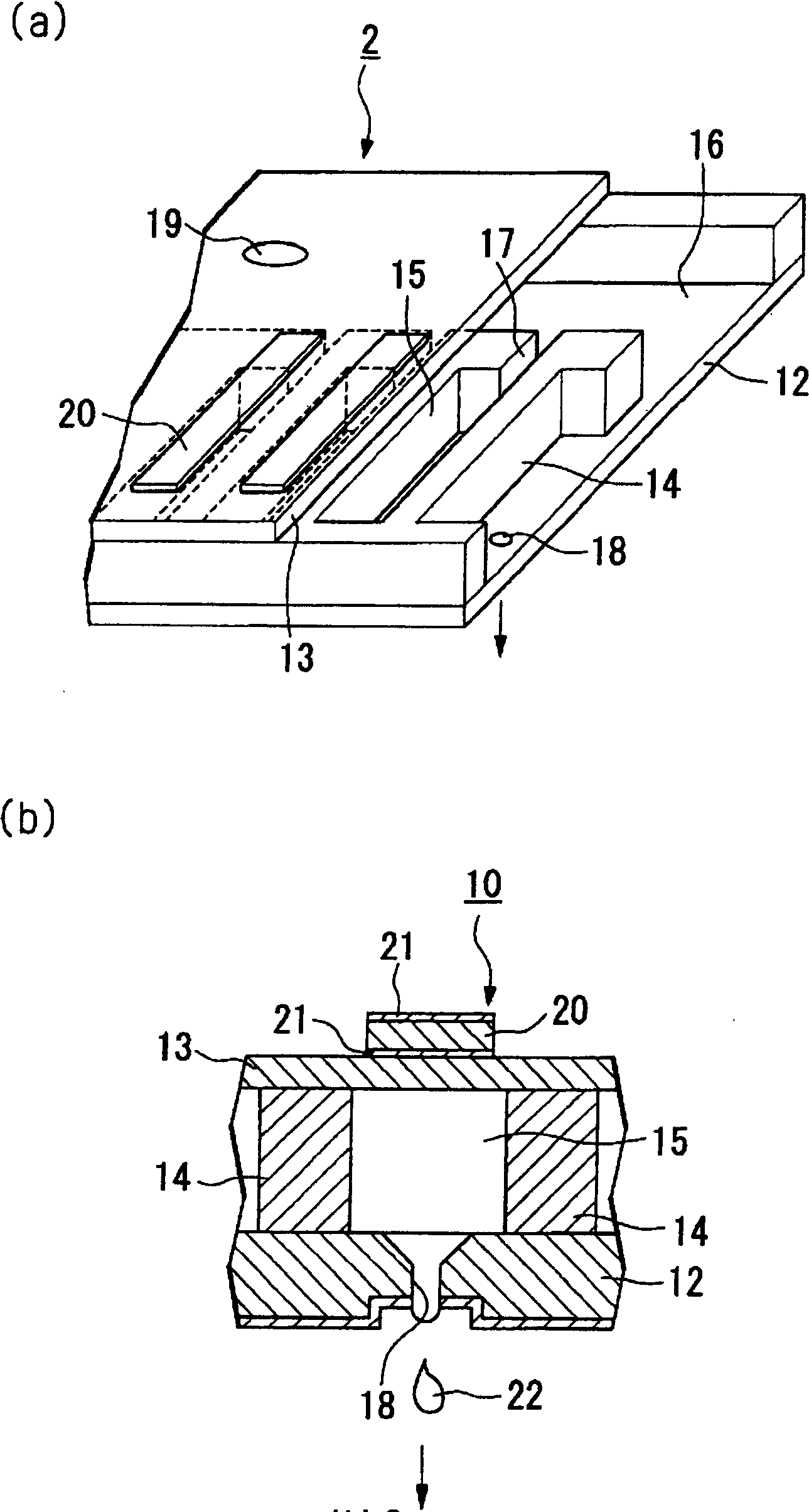

[0042] figure 1 Is a diagram showing an embodiment of the thin film forming apparatus of the present invention, figure 1 Symbol 1 in is a thin film forming device. The thin film forming device 1 is used in a liquid crystal device (Liquid Crystal Display: liquid crystal display device) to form a thin film on its substrate, and in this example, it is used particularly on a substrate SUB on which a color filter is also formed. In order to form a protective film (planarization film), the coating liquid L is applied.

[0043] The thin film forming apparatus 1 includes: an ejection mechanism 3 having a droplet ejection head 2 that ejects a coating liquid L onto a substrate SUB; and a moving mechanism capable of relatively moving the positions of the droplet ejection head 2 and the substrate SUB 4; The control unit C that controls the ejection mechanism 3 and the moving structure 4; It also has a solvent vapor su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com