Optical three-dimensional moulding method and device

A three-dimensional modeling and optical technology, applied in the direction of additive manufacturing, manufacturing tools, 3D object support structure, etc., can solve the problems of slow modeling speed, discontinuous curing state, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

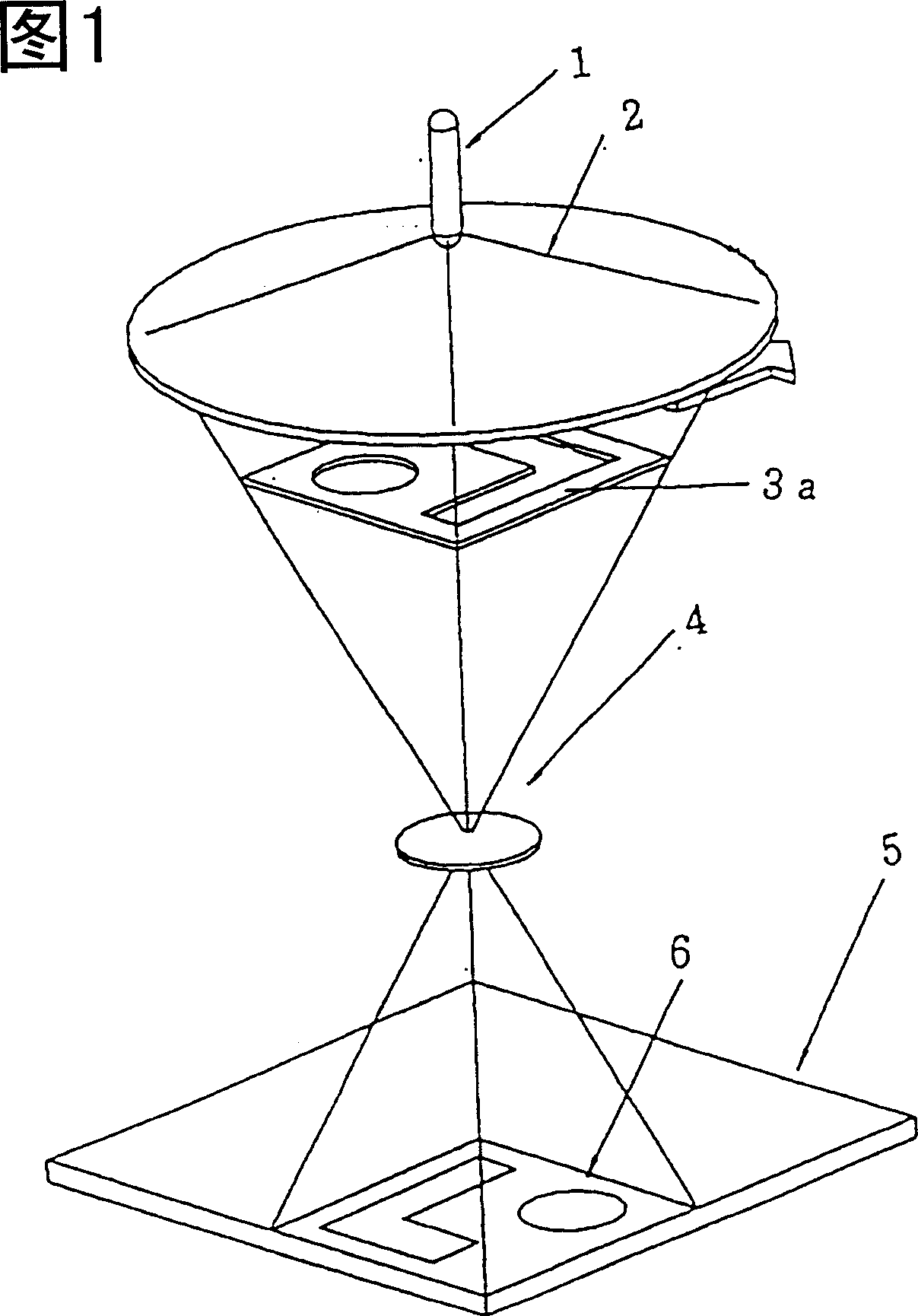

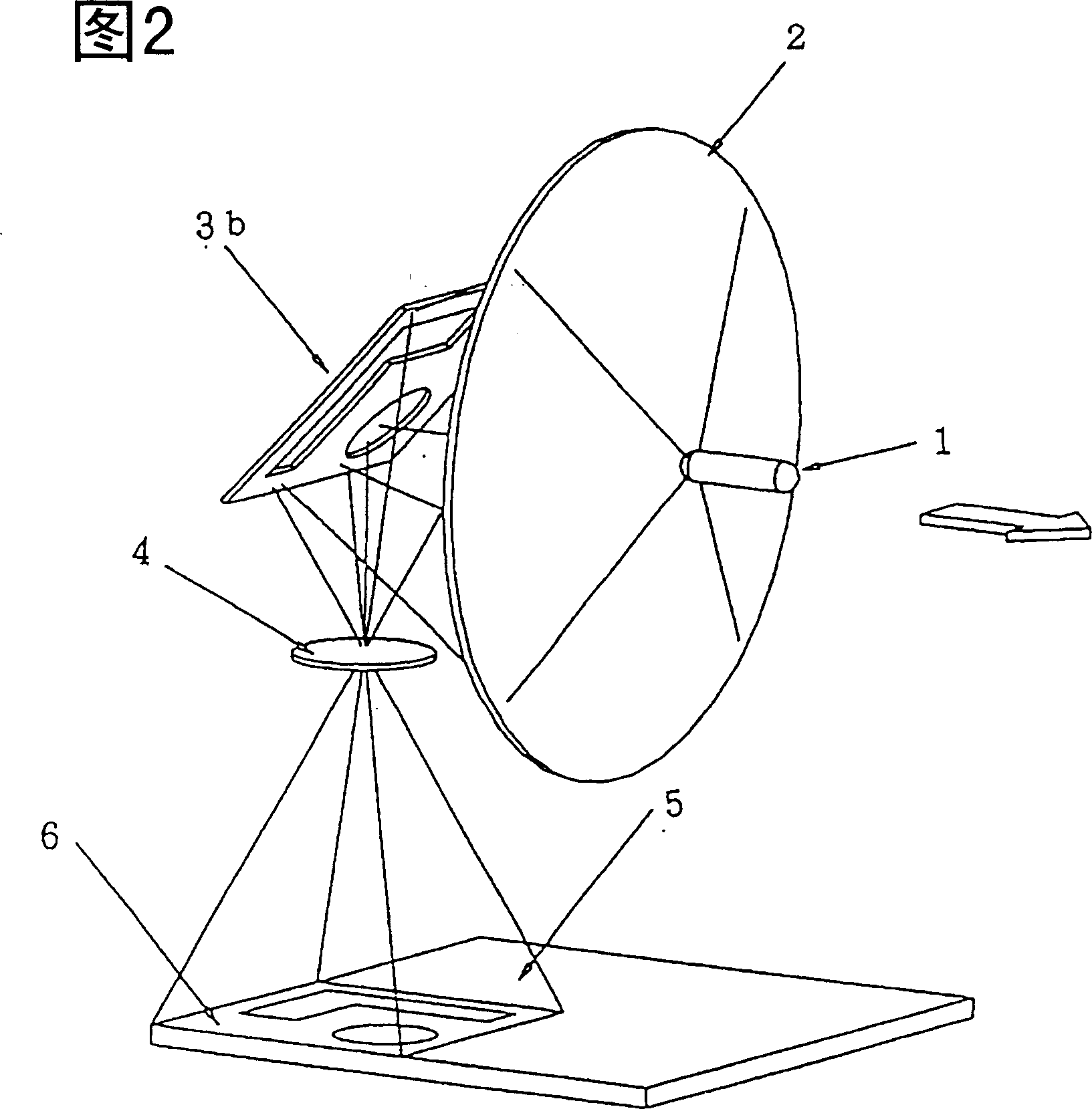

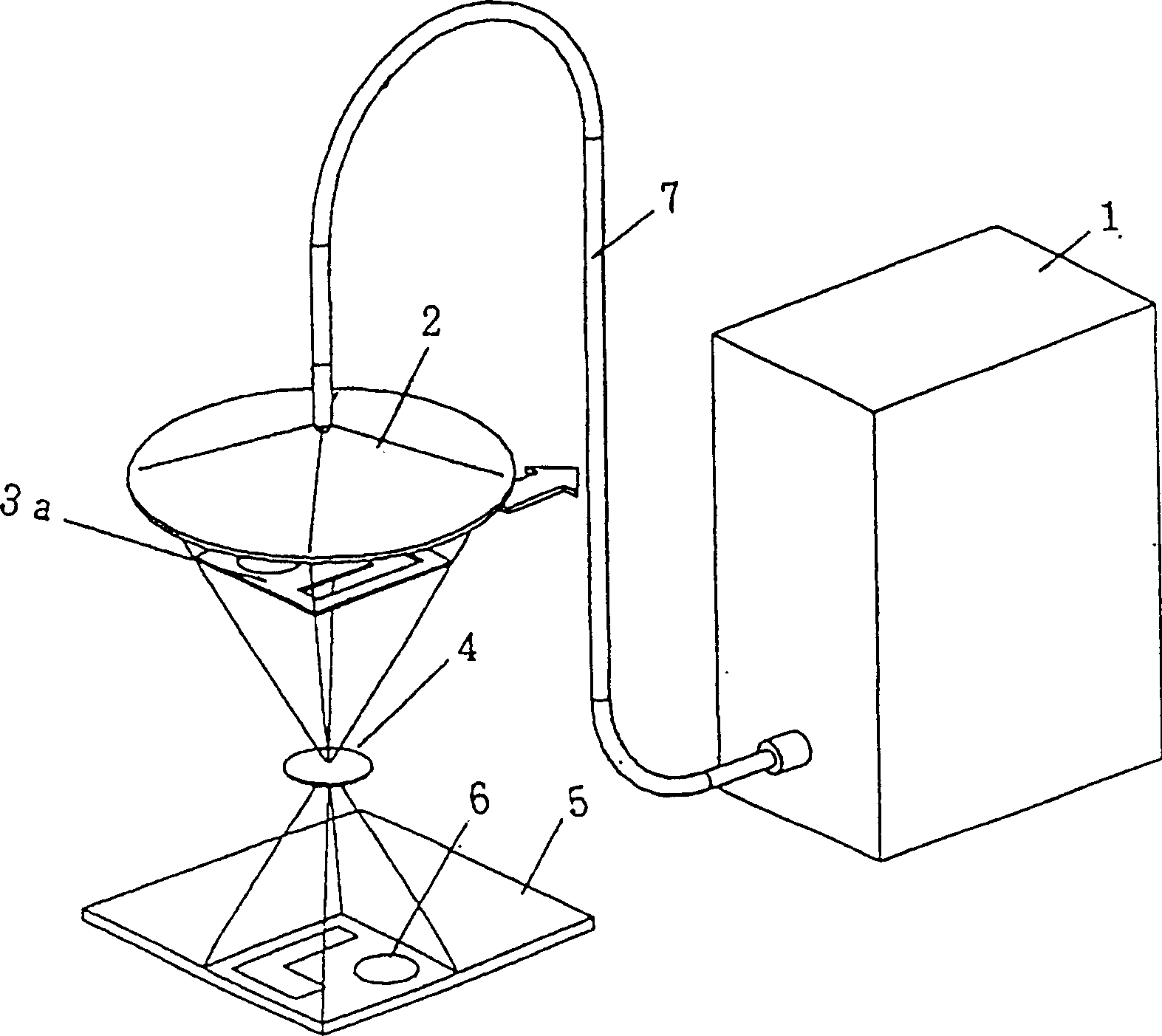

[0103]The light modeling device shown in FIG. 4 was used, where the light source 1 was a 150w metal halide lamp, and the planar drawing mask 3 was a TFT method VGA (800×640 pixels) liquid crystal made by EPSON, and a photocurable resin composition Adopting "Adekalasgua HSX-V2" manufactured by Asahi Denka Kogyo Co., Ltd. (curing sensitivity 5mJ), the projection size on the modeling surface 5 (the surface of the photocurable resin composition) = 35mm (the advancing direction of the device) × 47mm (Direction at right angles to the advancing direction) (square), light energy intensity on the modeling surface 5 1mw / cw 2 Under the conditions, according to the method shown in Figure 4, the light source 1, the condenser lens 2, the planar drawing mask 3, and the projection lens 4 are formed as a whole, and move parallel to the modeling surface 5 at a speed of about 7mm / sec. The direction is continuously moved. At this time, according to the cross-sectional shape pattern of the mask image ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com