Apparatus and system for containment of oil spills

A kind of equipment and groove technology, which is used in transportation and packaging, special-purpose ships, cleaning of open water surfaces, etc., can solve problems such as stability and rise, and achieve the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

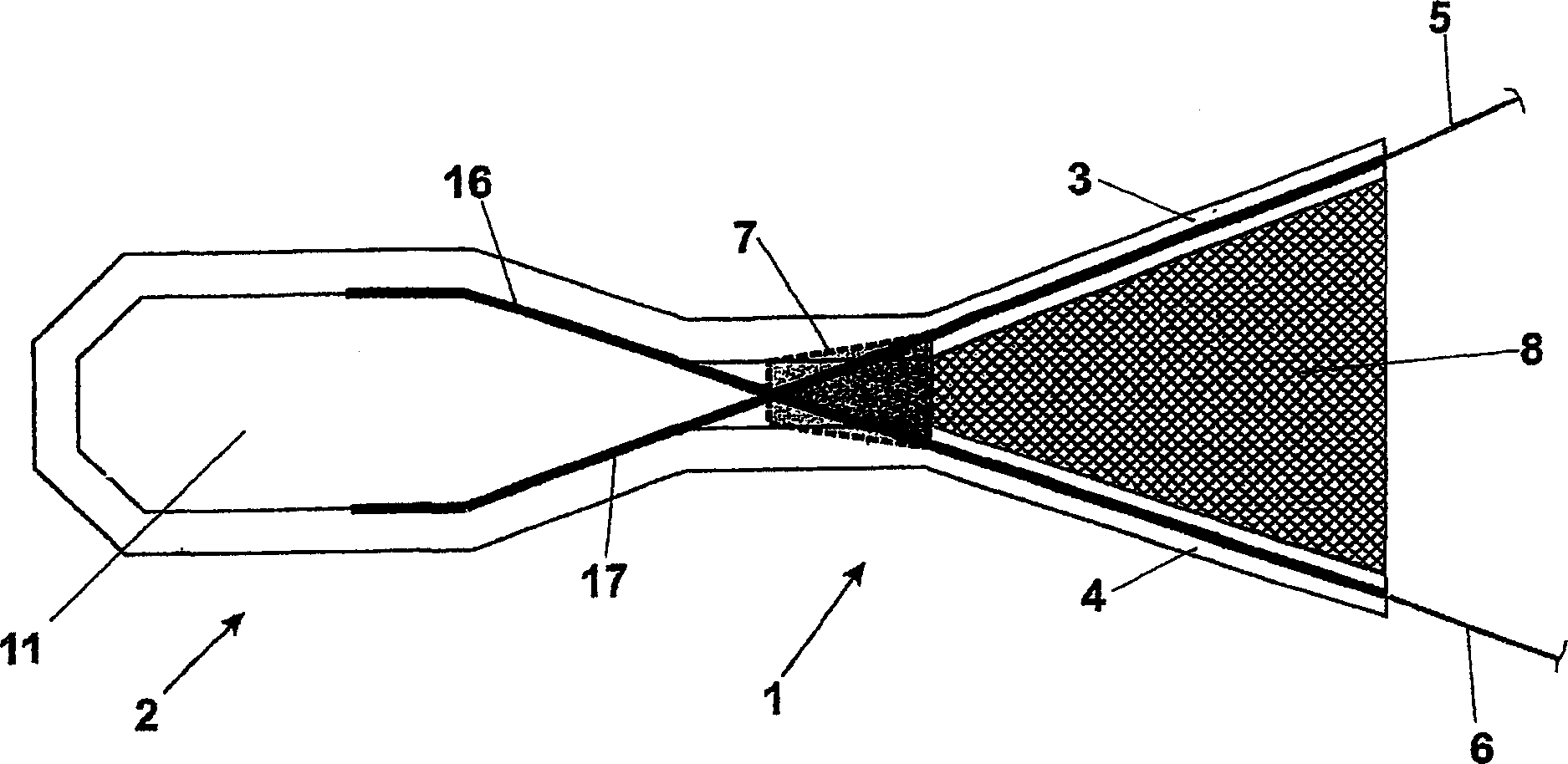

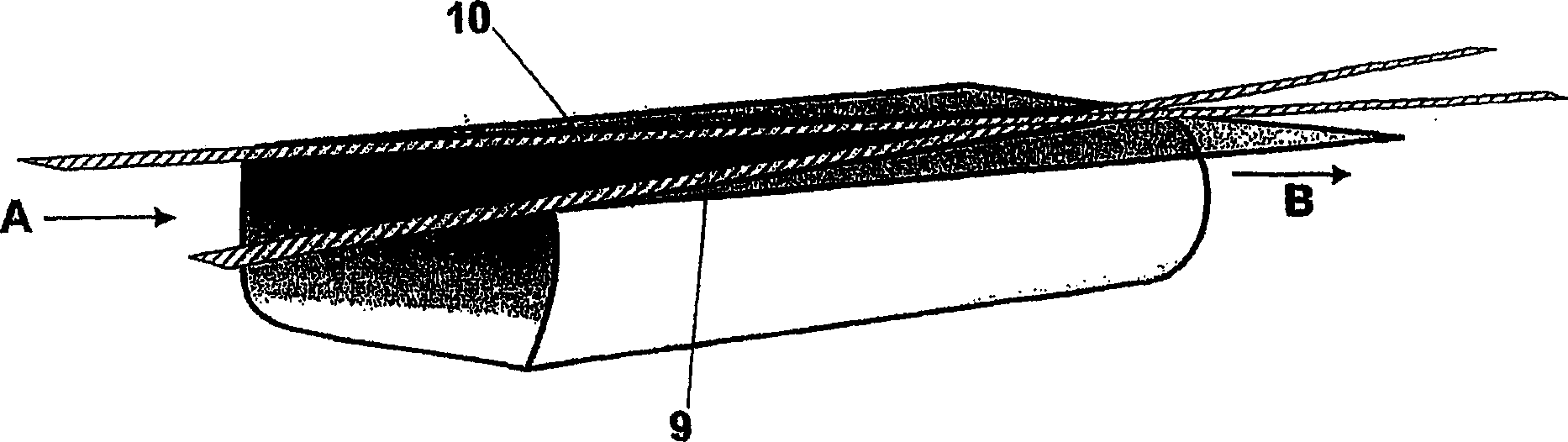

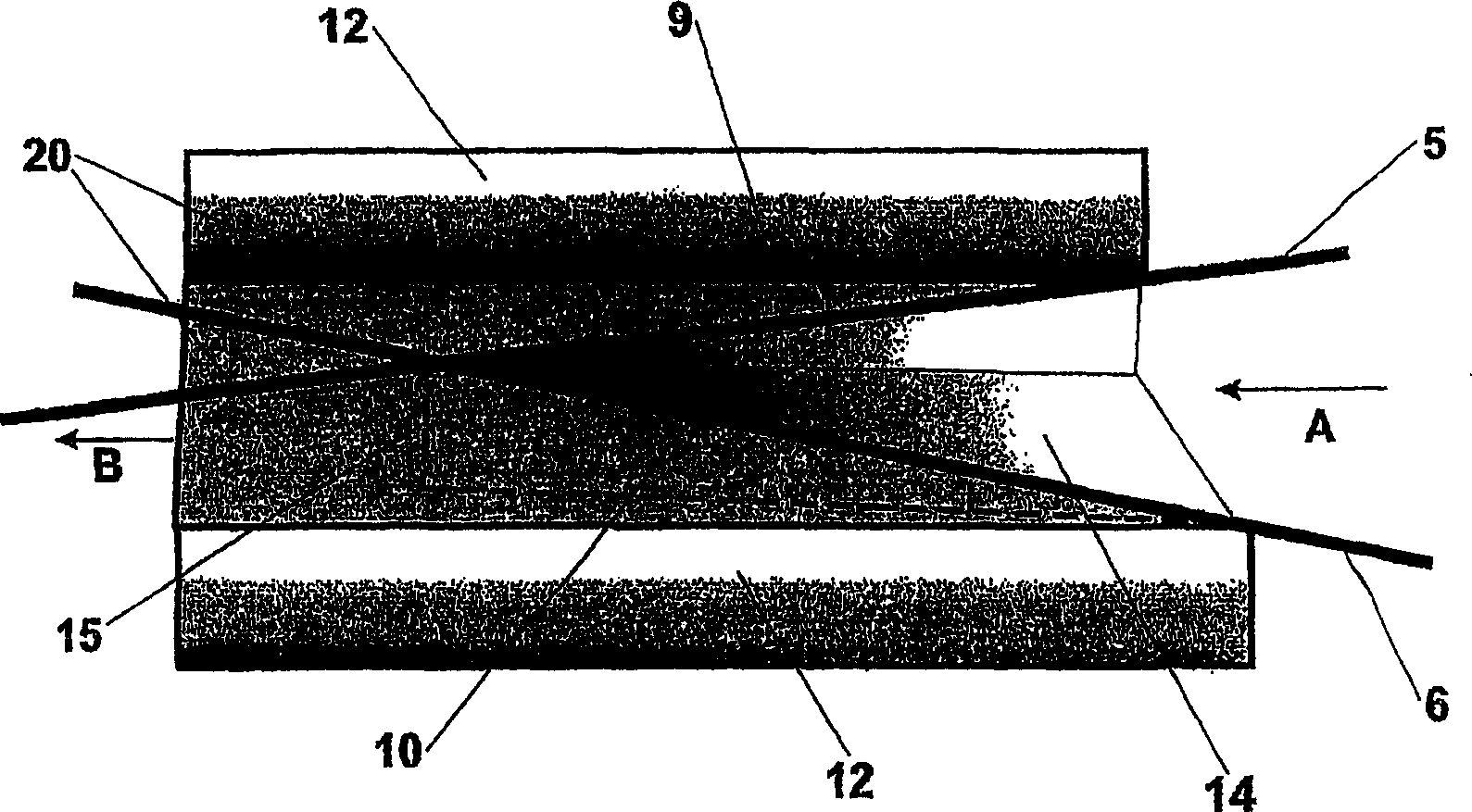

[0024] The device or system according to the invention is basically made of suitable non-rigid and flexible materials so that it can be stored in rolls. An example of a suitable material to use is a sheet of suitable plastic that is strong, weatherproof and oil (and chemical) resistant. The device comprises a front tapered gutter section 1, a rear collector or separator section 2, and a wedge-shaped structure 7 between said sections.

[0025] The tapered groove portion 1 is in the form of surfaces 3 , 4 defined by two sides extending from a wedge-shaped structure 7 . as in Figure 4 As seen in , the surfaces 3 , 4 include a freeboard 12 and a side edge 13 and preferably also an inlet bottom 8 . Said bottom 8 in the form of a mesh serves, in addition to forming a "demarcation line", to maintain the shape of the tapered groove part 1 and the inlet of the duct 14 as wedge-shaped structure 7 . The topside 12 is normally ballasted by hydraulic pressure when the equipment or syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com