Agricultural machine

A working machine and machine body technology, applied in agriculture, applications, motor vehicles, etc., can solve the problems of increasing the weight of the machine body, not being able to support the rear cover of the body frame, increasing manufacturing costs and management costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

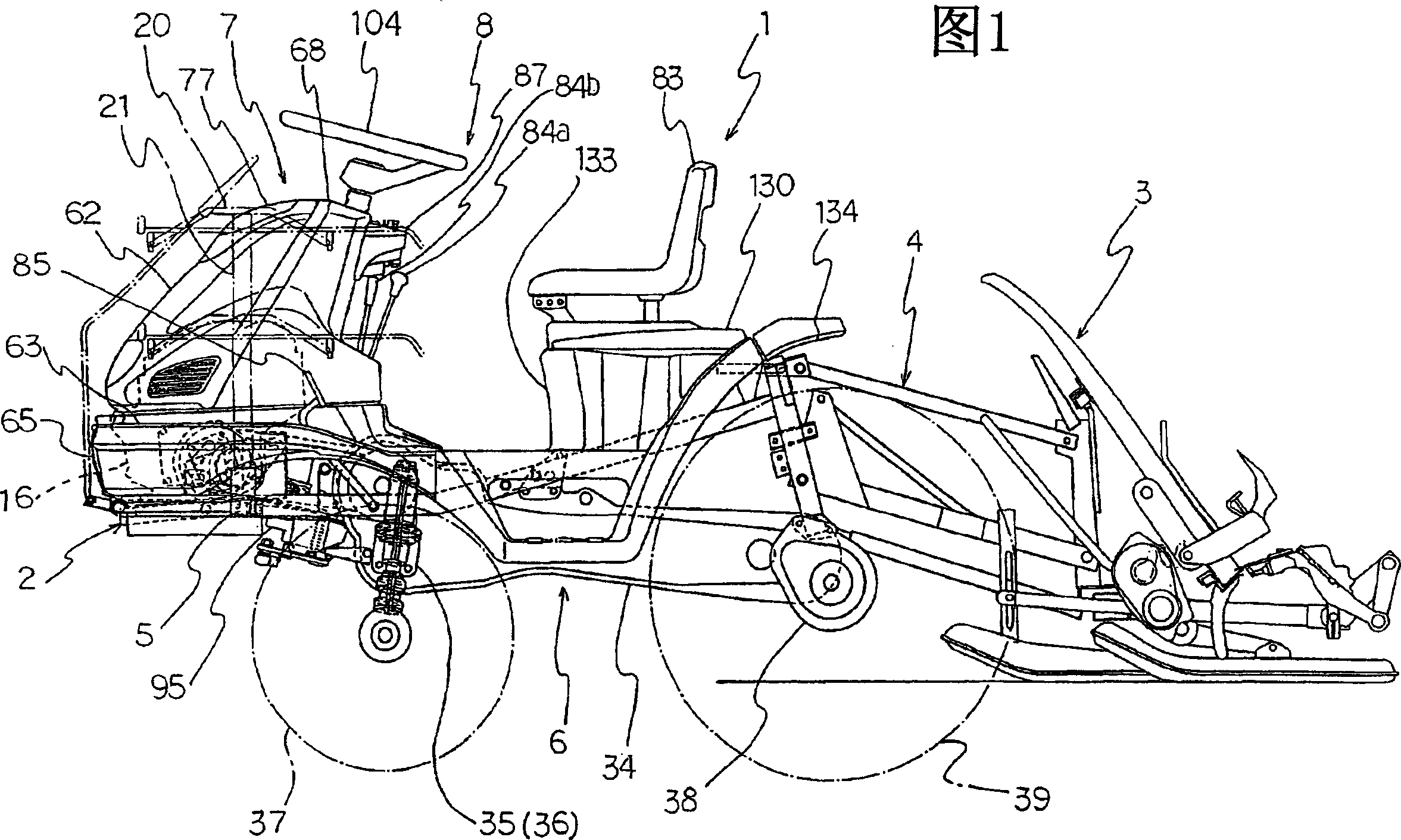

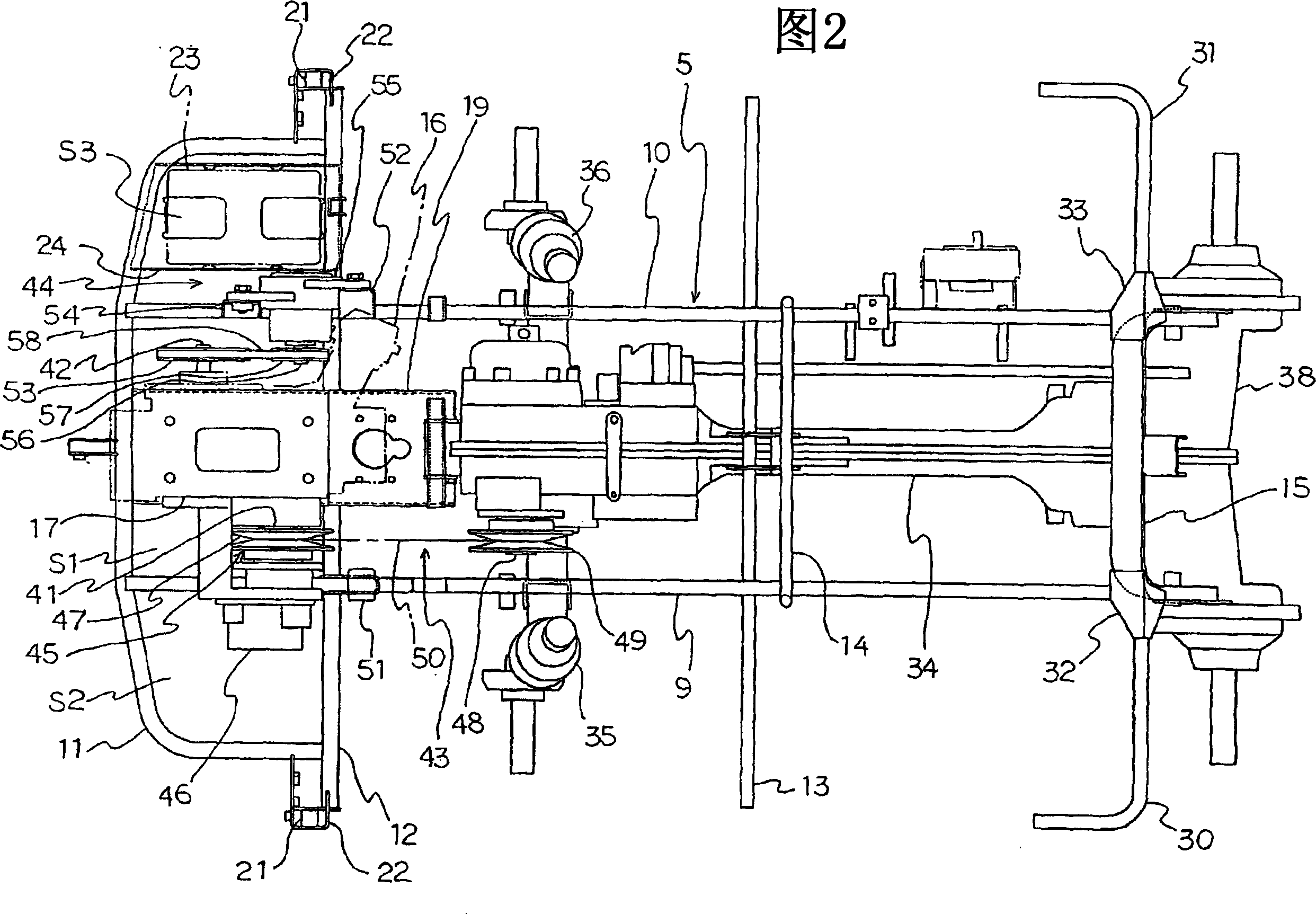

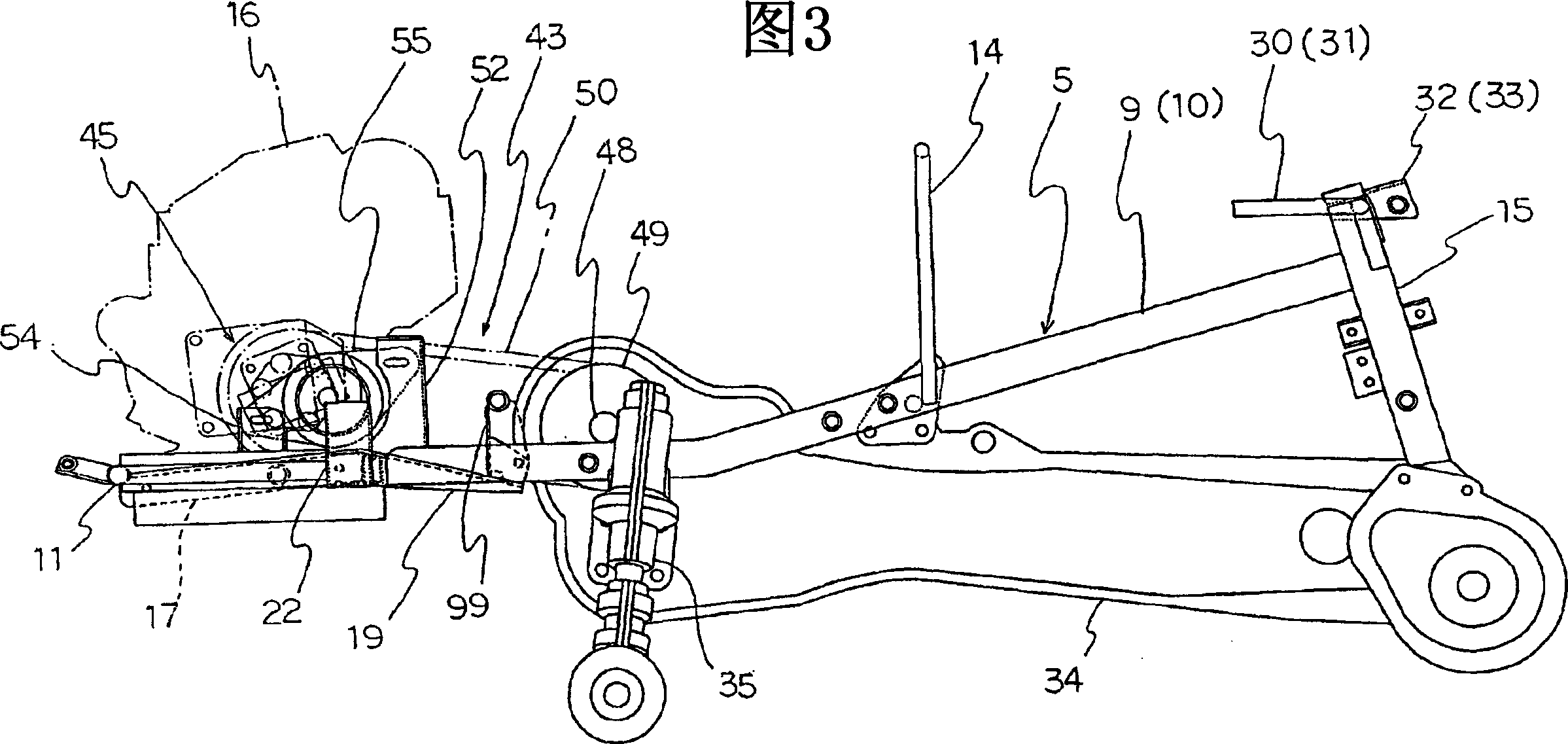

[0052] Next, an embodiment of the present invention will be specifically described with reference to the drawings. In this embodiment, the rice transplanter 1 as the agricultural work machine of the present invention will be described as an example. The agricultural work machine of the present invention is not limited to the rice transplanter 1, and can also be used in trucks, combine harvesters, vegetable transplanters, etc. Various agricultural work machines.

[0053] Rice transplanter 1, as shown in Figure 1, is connected with seedling transplanting machine 3 by elevating mechanism 4 on the rear portion of the walking body 2 that can be made to advance automatically.

[0054] As shown in FIG. 1 , the traveling body 2 is configured with a traveling portion 6 below the body frame 5 , a prime mover portion 7 at the front of the body frame 5 , and an operating operation portion 8 at the rear of the prime mover portion 7 .

[0055] Hereinafter, the structure of each part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com