High-hygroscopic polypropylene fibre

A polypropylene fiber, high moisture absorption technology, applied in the field of polypropylene fiber, can solve the problems of lack of micropores and gaps, poor hygroscopicity of polypropylene fiber, etc., and achieve the effect of good hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

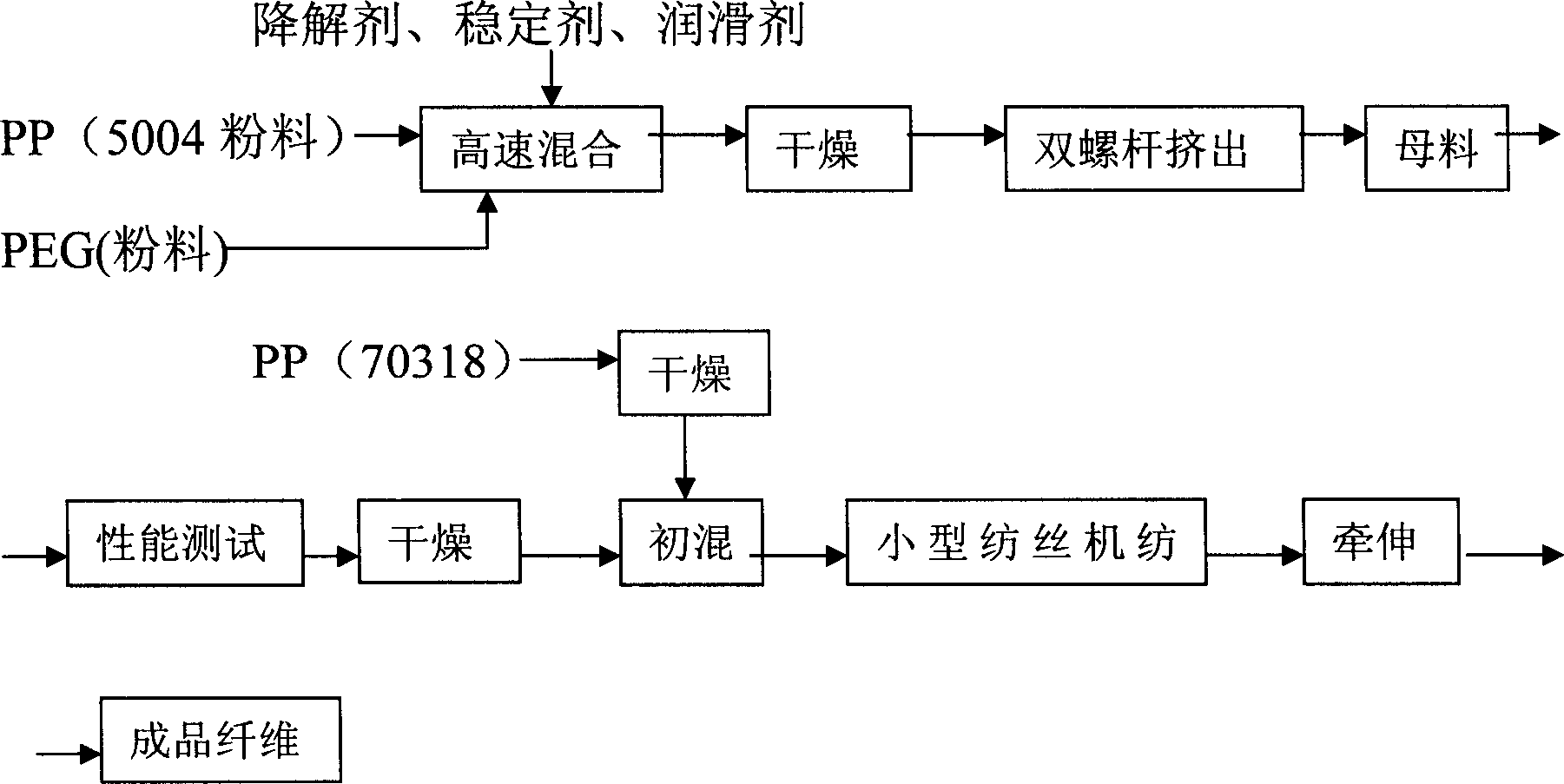

[0008] It can be seen from the accompanying drawings that based on the preparation of 15% (or 30%) masterbatch, accurately measure polyethylene glycol and carrier polypropylene powder and 0.05% calcium stearate (0.1 calcium stearate), 0.1% stable Agent 330 (0.3% stabilizer 330), 0.04% degradation agent BTBP (0.1% degradation agent BTBP) powder, and carrier powder are added to a high-speed mixer and mixed, melted and extruded through a twin-screw extruder, cooled, and manufactured Granulated into modified masterbatch. During spinning, the dried modified masterbatch is uniformly mixed with fiber-grade polypropylene pellets at a total content of 1%-20%, melt-spun and post-processed to make modified fibers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com