High power lighting system and fluorescent lamp

A lighting system, fluorescent lamp technology, applied in the field of fluorescent lamps, can solve the problems of electronic current reduction, poor cooling effect, electrode filament consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

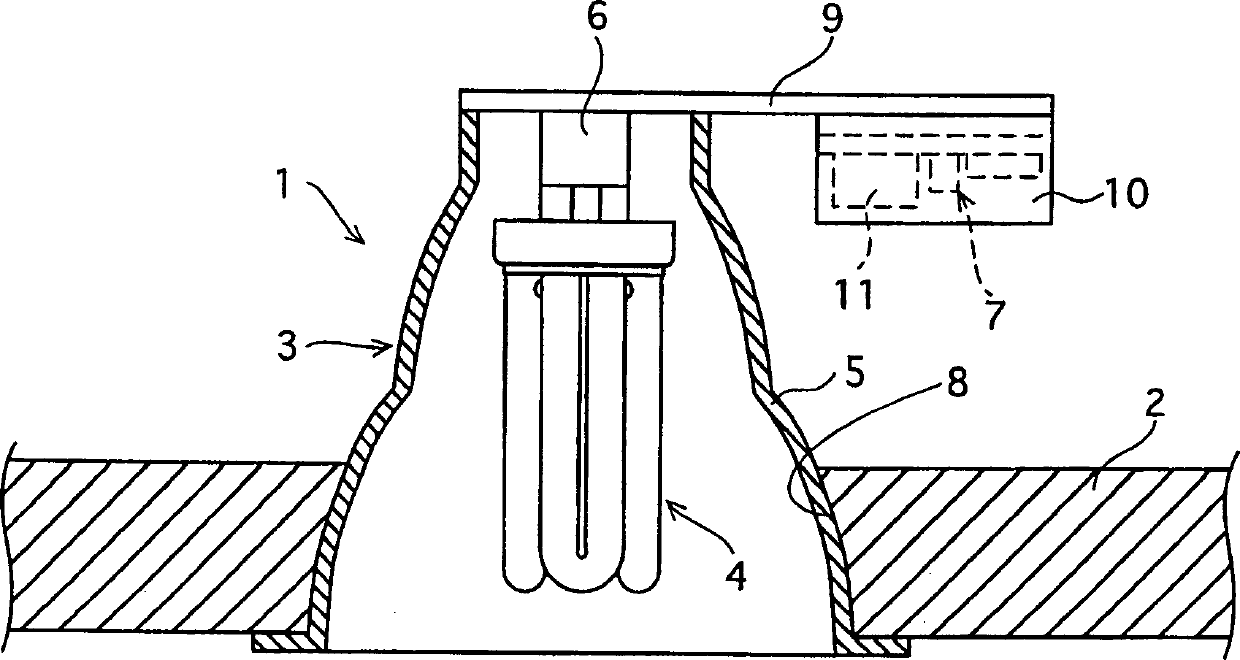

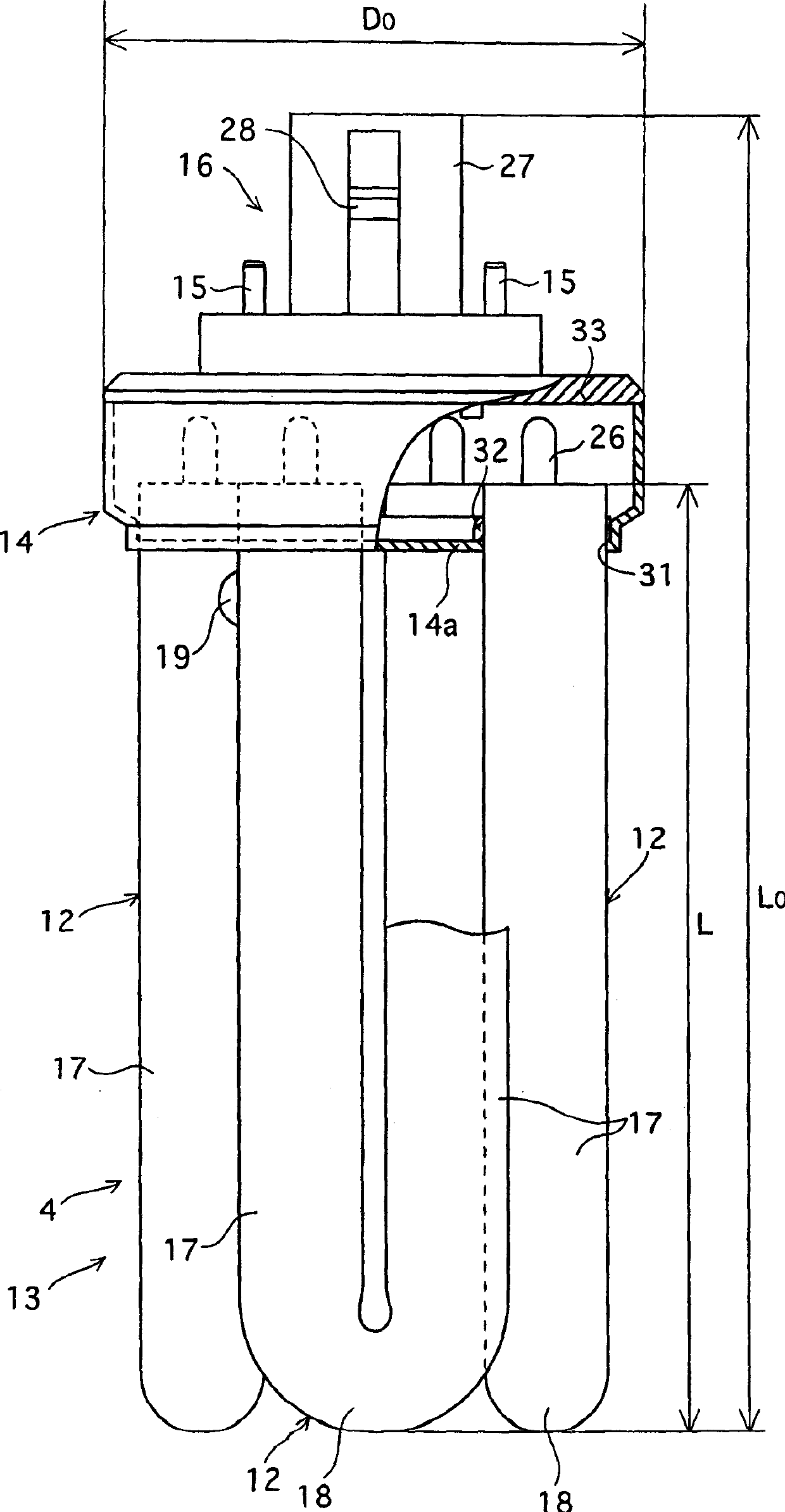

[0030] Hereinafter, an embodiment in which the lighting system of the present invention is applied to a down lighting device will be described with reference to the drawings.

[0031] I. Structure of downward lighting device

[0032] Fig. 1 is a view showing the overall construction of the downlighting device of the present invention, in which a part of the drawing is cut away to show the internal structure. As shown in the figure, the down lighting device 1 includes a main body 3 embedded in a ceiling 2, and a compact single-cap fluorescent lamp 4 (hereinafter simply referred to as "fluorescent lamp 4") connected to the main body 3.

[0033] (1) Subject

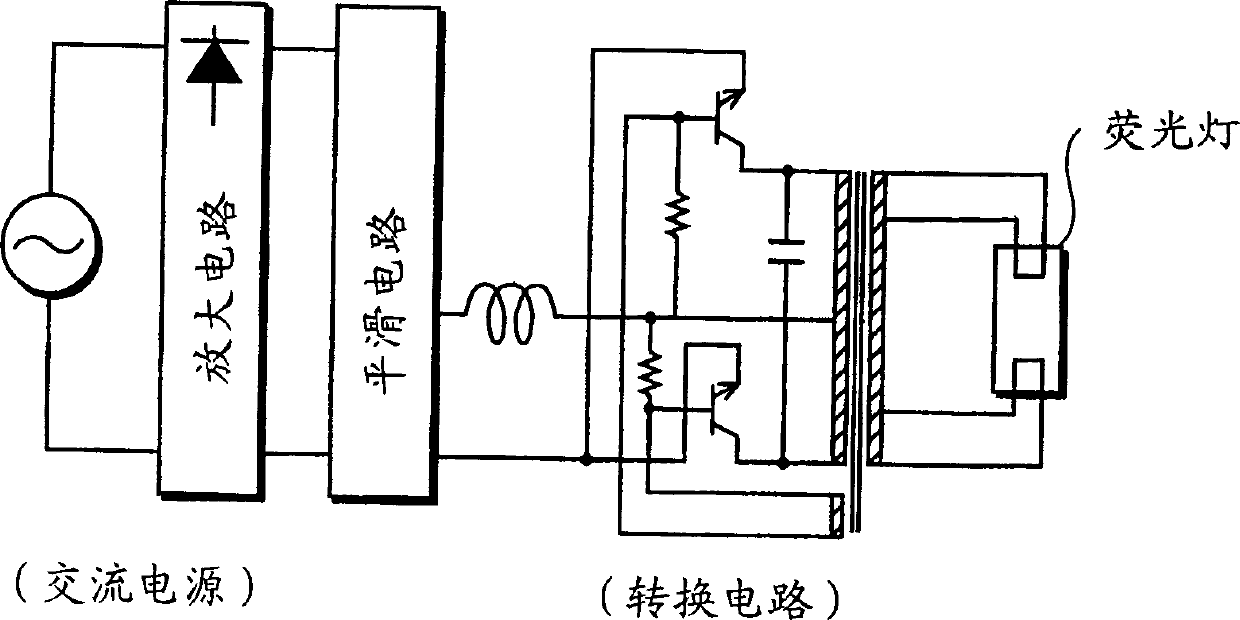

[0034] The main body 3 is provided with a shading assembly 5 expanding downwards, a socket assembly 6 disposed within the shading assembly 5 for detachably connecting the fluorescent lamp 4 thereto, and a fluorescent lamp operatively connected to the socket assembly 6 at maximum brightness level and dimming level 4 electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com