Halogen lamp

A halogen lamp and halogen technology, applied in the field of halogen lamps, can solve the problem of high cost and achieve the effect of avoiding the blackening of the lamp tube

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

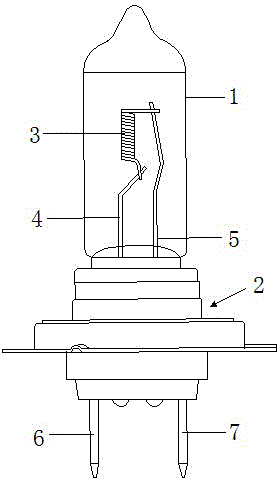

[0015] The drawing shows a schematic diagram of the structure of a halogen lamp according to a preferred exemplary embodiment. Such halogen lamps are so-called H8 lamps, which are intended to be operated in motor vehicles with a nominal voltage of 12 volts. The lamp has a maximum power consumption of only 43 watts at an operating voltage of 13.2 volts.

[0016] The halogen lamp according to the preferred exemplary embodiment has a substantially cylindrical glass bulb 1 which is provided with a base 2 at one end. An axially oriented spiral filament 3 is arranged inside the lamp tube 1 , and the filament outlet wrapped with a small molybdenum tube is welded with the current leads 4 and 5 respectively. The two current leads 4 , 5 are electrically conductively connected to the electrical connections 6 , 7 of the lampholder 2 respectively. The lamp tube 1 is made of quartz glass or hardened glass, for example aluminosilicate glass.

[0017] A filling with a halogen component and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com