Locomotive anti-slide apparatus

A locomotive and hydraulic device technology, applied in the field of anti-slip devices for rail vehicles, can solve problems such as inability to timely feedback anti-slip information, failure to prompt operators, and many hidden dangers of accidents, so as to prevent locomotive slipping accidents and facilitate and reliable control operation , The effect of convenient operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

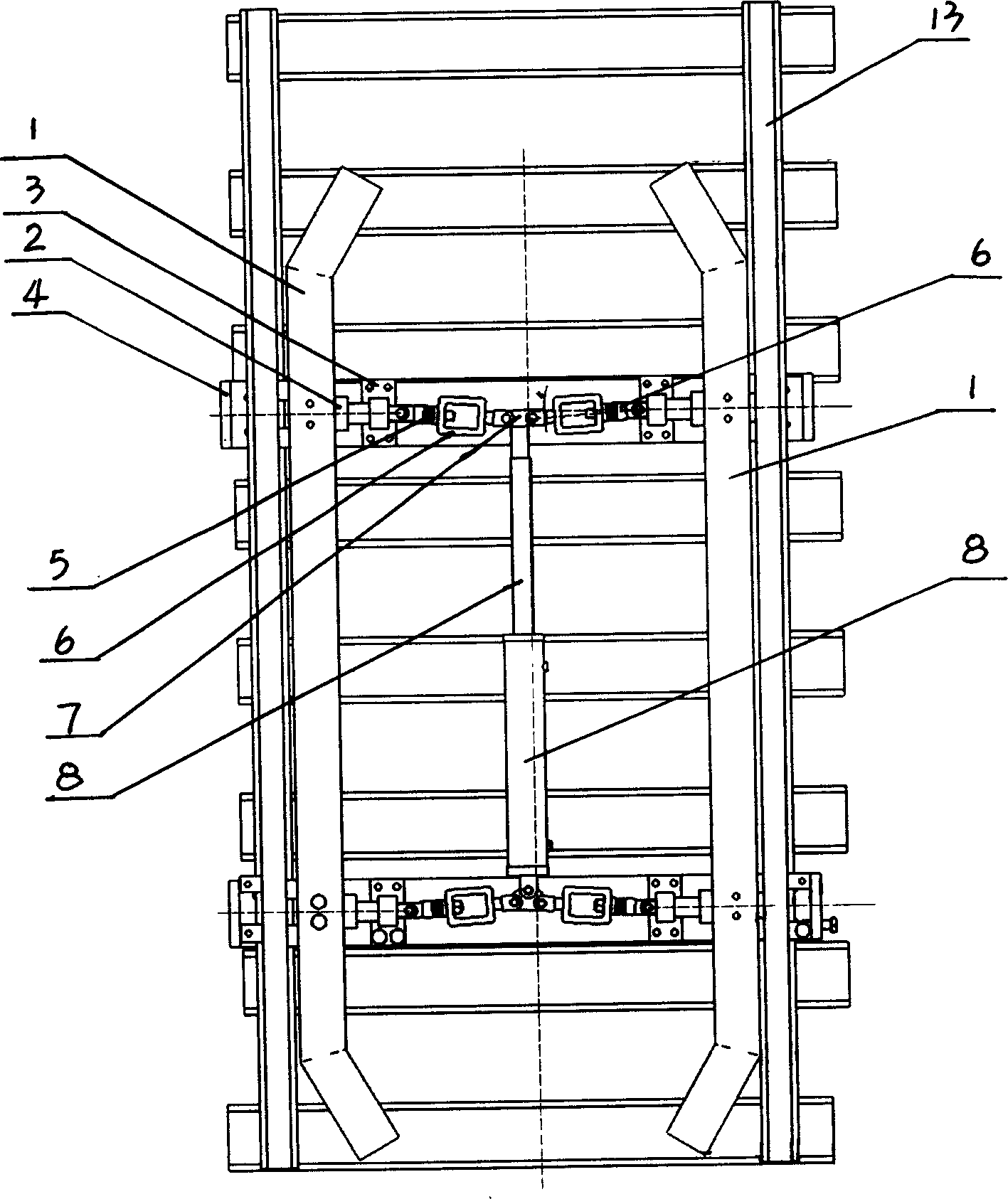

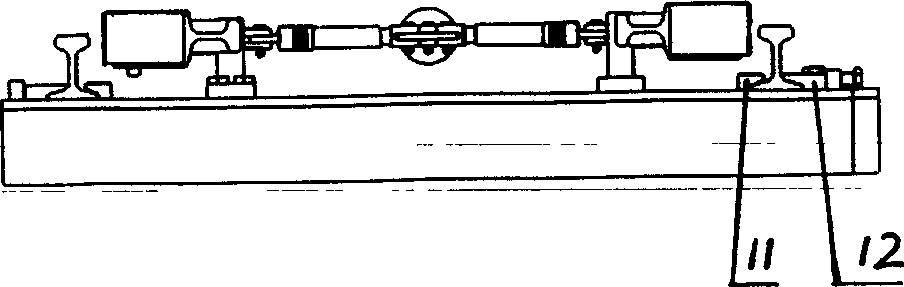

[0025] Such as figure 1 , figure 2 , image 3 As shown, the locomotive anti-slip device includes a brake rail 1, a telescopic mechanism, a hydraulic device, and a control system. The middle of the brake rail 1 is a brake section, and the two ends are guide sections. Two brake rails 1 are used for braking. The sections are connected by a telescopic mechanism, and there are 2 telescopic mechanisms on the brake section, and the connecting piece 7 between the 2 telescopic mechanisms is movably connected to a hydraulic cylinder 8 of a hydraulic device, a hydraulic pump of the hydraulic device and a control circuit of the control system connected.

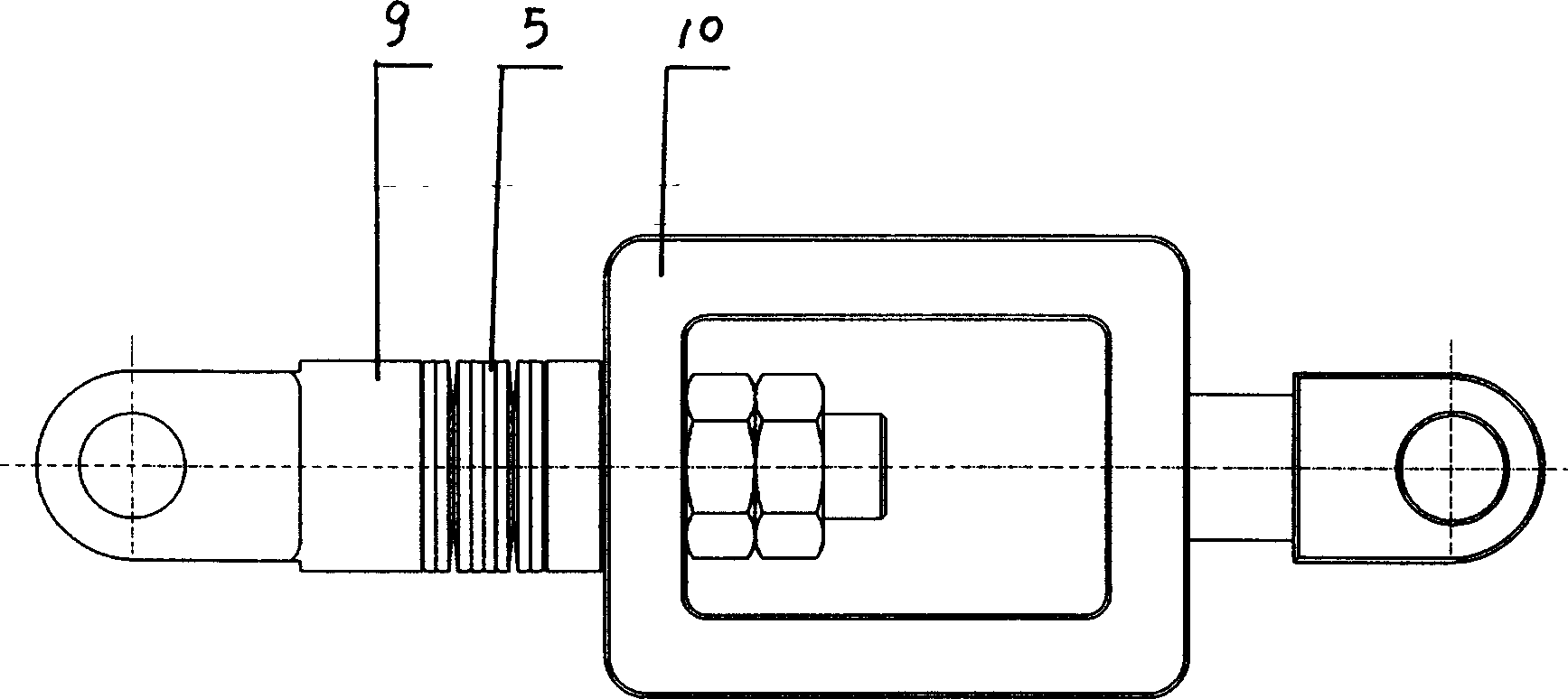

[0026] The telescopic mechanism is mainly composed of 2 telescopic components, a connector 7 and a joist 4, the 2 telescopic components are respectively connected with the connector 7, and the connector 7 is connected with the hydraulic cylinder 8; each telescopic component is mainly composed of a telescopic The arm 2, the support 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com