Elevator balance compensating chain and manufacturing method thereof

A balance compensation and elevator technology, applied in the traction chain field, can solve the problems of poor wear resistance and tear resistance of the dipping layer, easy wear or cracking, and falling off of the dipping layer, etc. The effect of saving manufacturing and installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the elevator balance compensation chain of the present invention will be further described below in conjunction with the accompanying drawings.

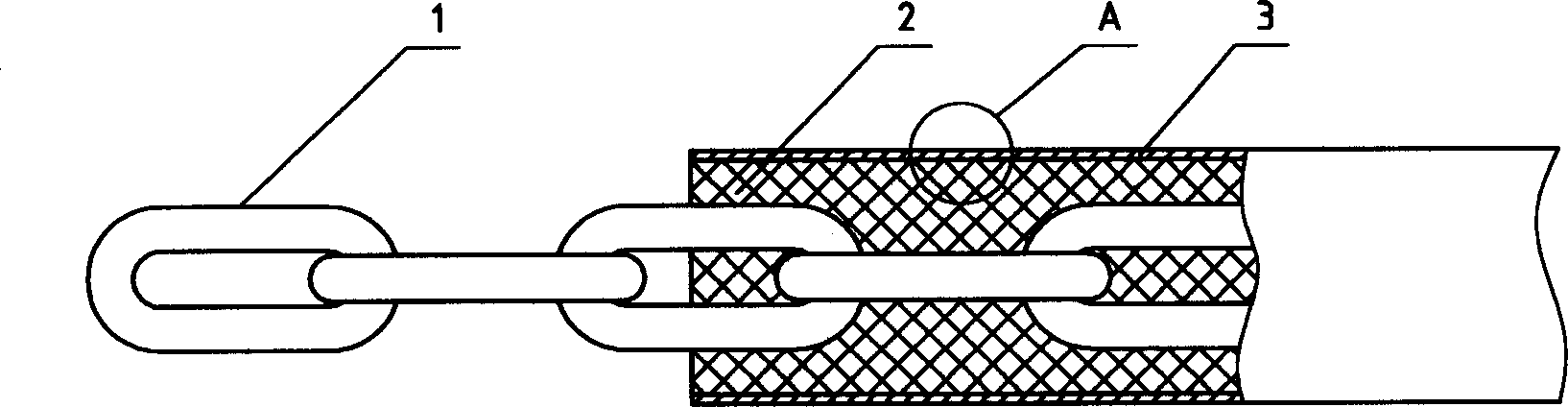

[0032] Figure 1 ~ Figure 3 It is the elevator balance compensation chain shown in the present invention, which includes an iron chain 1, a rubber cylinder 2, and a fiber layer 3. The iron chain 1 is placed in the rubber cylinder 2, and the rubber cylinder 2 is wrapped with a fiber layer 3.

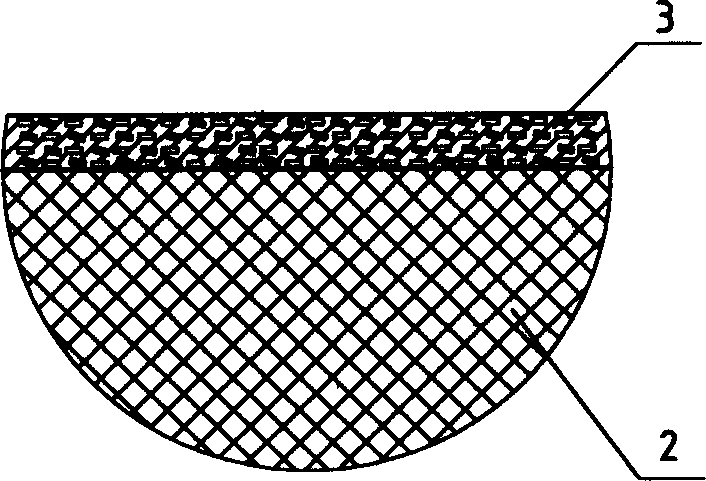

[0033] The above-mentioned fiber layer 3 is composed of short fibers and rubber or plastic or rubber-plastic, and the above-mentioned short fibers are uniformly distributed in the matrix of the above-mentioned rubber or plastic or rubber-plastic, and the thickness of the fiber layer 3 is 0.5-3.5 mm.

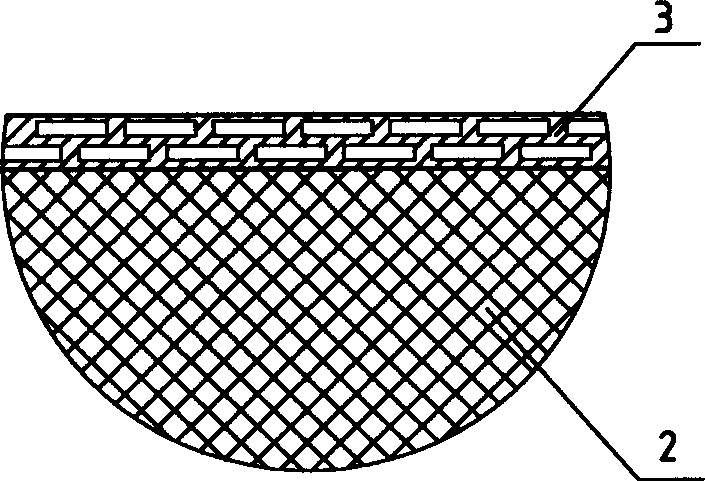

[0034] The above-mentioned fiber layer 3 is composed of fiber cloth and rubber or plastic or rubber-plastic, and the above-mentioned rubber or plastic or rubber-plastic is uniformly coated on the above-mentioned fiber clot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Radial thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com