Antifriction bearing apparatus

A technology for rolling bearings and launching devices, which is applied in the direction of rolling contact bearings, roller bearings, bearing assembly, etc. It can solve problems such as troublesome assembly, high precision, and breakage, and achieve the effects of preventing cost increases, improving detection accuracy, and simplifying manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

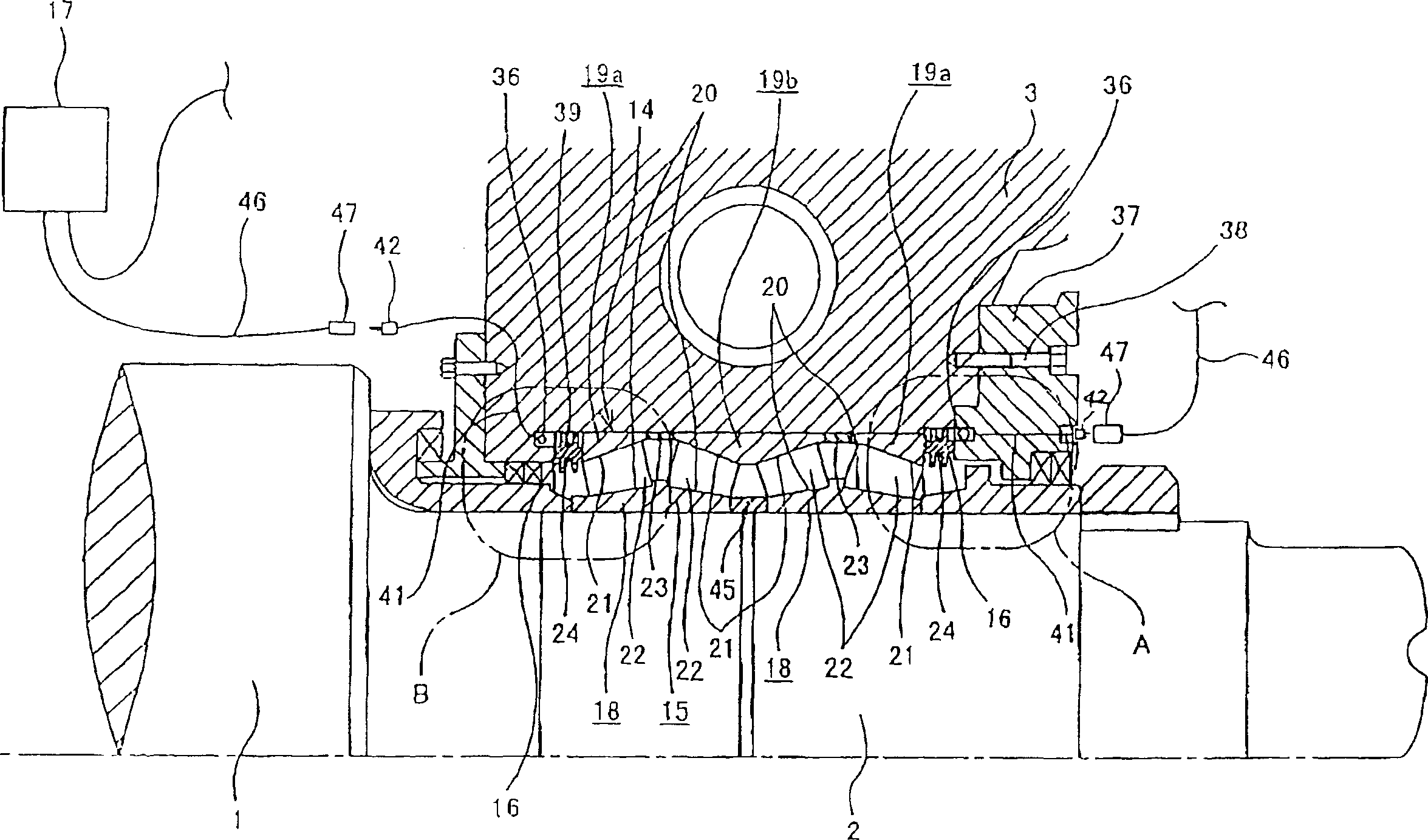

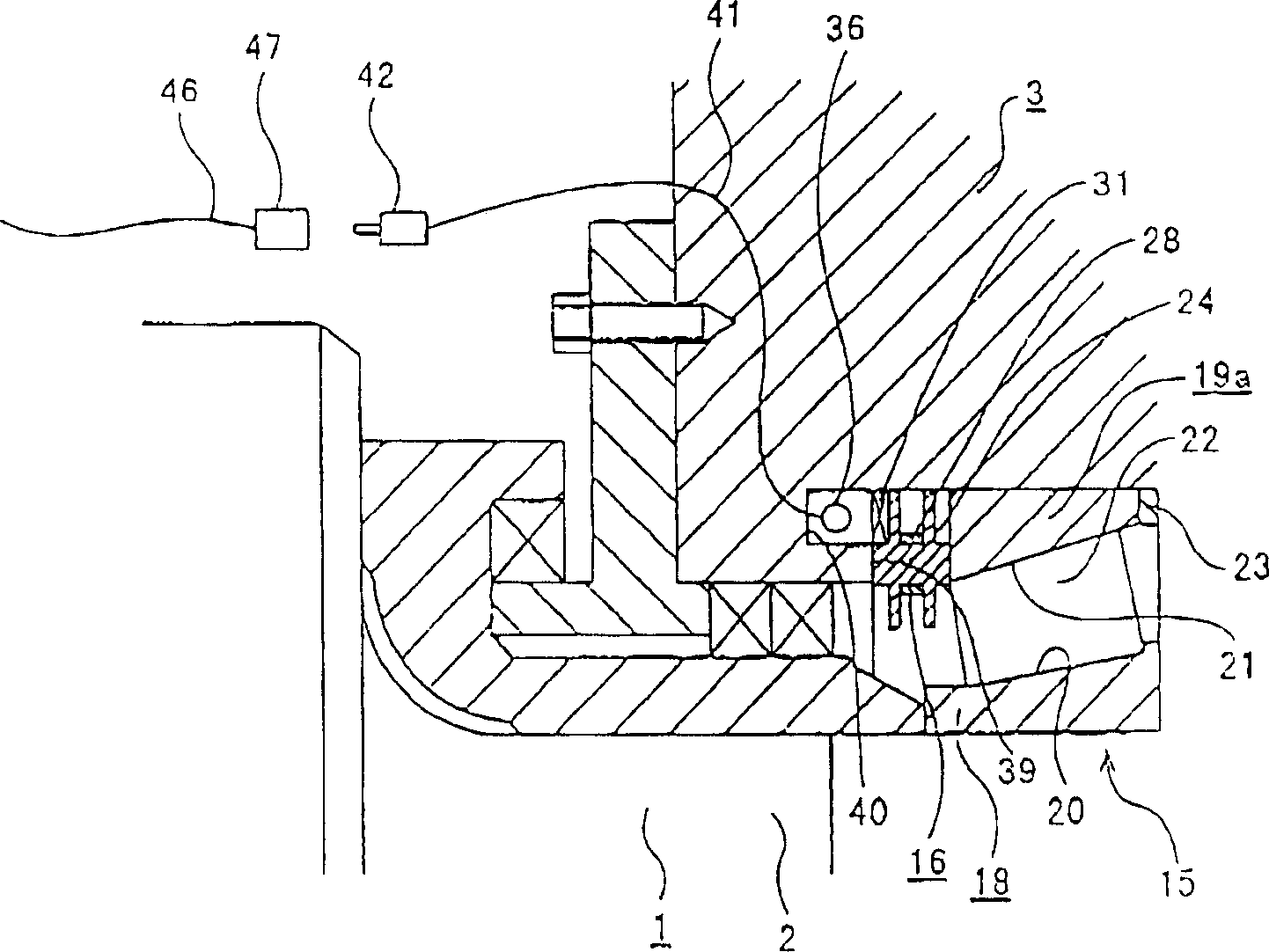

[0040] Figures 1 to 7 Each of the figures in FIG. 1 shows a rolling bearing device with a sensor device according to a first embodiment of the present invention. In the first embodiment, the two axial ends of the roll 1 rolling in the rolling mill, the rolling bearing device 14 with the sensor is connected in the rotating support part, so as to roll metal material such as steel. In detail, the roll neck 2 is disposed at the central portion on both axial ends of the rolling roll 1, and is rotatably supported within the housing 3 by four-row tapered roller bearings 15 even during use. The housing does not rotate either. The rolling bearing device 14 includes: a four-row tapered roller bearing 15, a pair of sensor devices 16, 16, a pair of second coils 36, 36, and an external input / output device 17 (Fig. 6). The four-row tapered roller bearing 15 includes: a pair of inner rings 18, 18, three outer rings 19a, 19b, raised conical inner ring raceways 20, 20, concave conical outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com