Combined pile section with reinfored horizontal bending strength and rigidity and its construction method

A technology of flexural strength and pile segments, which is applied in the field of locally reinforced structures and construction, can solve problems such as difficulty in strength and stiffness, great difference in stiffness, superposition of horizontal thrust, etc., and achieve a reduction in the ratio of price to bearing capacity and retention Vertical bearing capacity, easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

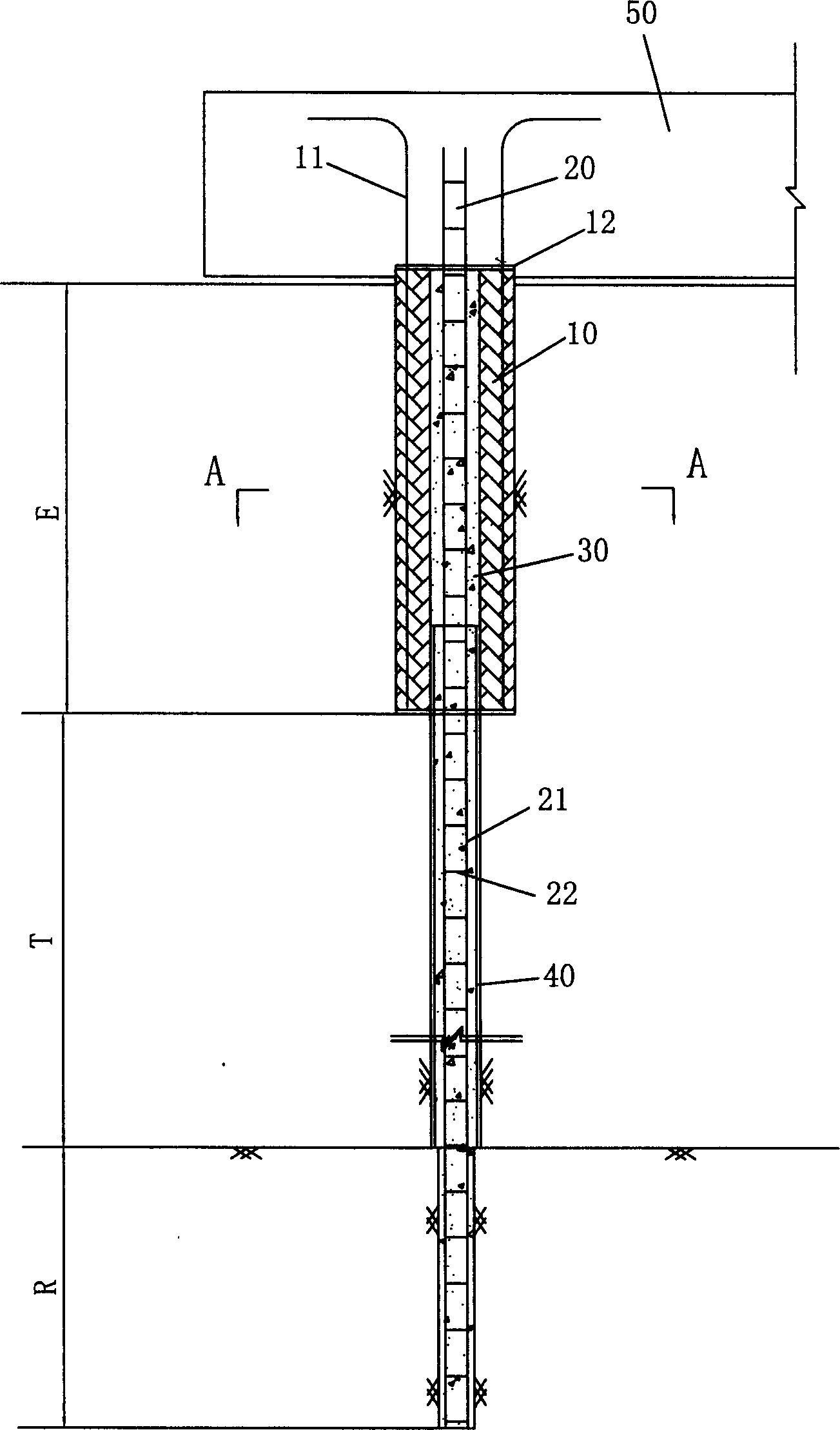

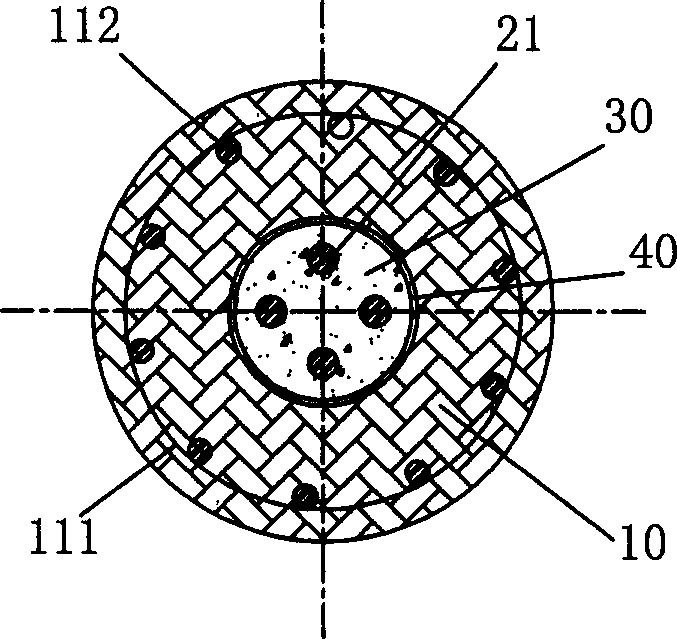

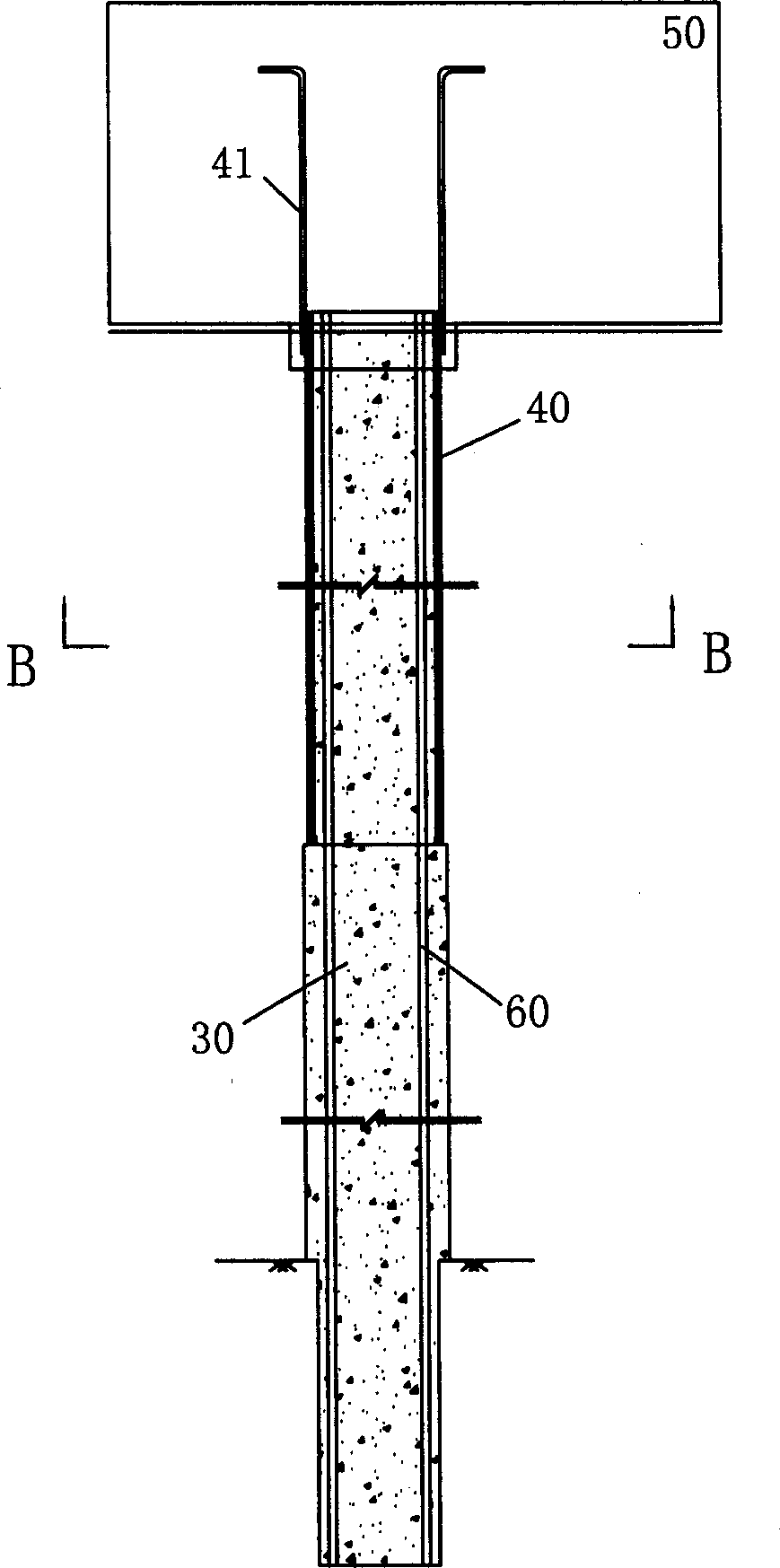

[0045] figure 1 It is the first embodiment of the combined pile segment of the present invention, and it is a longitudinal section view of a combined structure of a small-diameter foundation pile with bending strength and rigidity. Since small-diameter foundation piles are generally limited to bear loads along the direction of the pile axis, and cannot rely on the bending stiffness of the pile body to bear the horizontal force perpendicular to the direction of the pile axis, the end of the small-diameter foundation pile of the present invention increases Strengthening the pile structure, thereby forming a combined structural pile section, can significantly increase its resistance to bending. Such as figure 1 with figure 2 As shown in the first embodiment of the present invention, the combined structural pile section is provided with prefabricated pipe piles 10 on the periphery of the small-diameter foundation pile 20 on a certain length E, and structural materials 30 are fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com