Foil gange deep sea insulation method and device

A strain gauge and deep-sea technology, applied in the direction of electromagnetic measuring devices, electric/magnetic solid deformation measurement, etc., can solve problems such as failure, damage to the mechanical properties of piles, strain gauges, and easy leakage detection of protective covers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

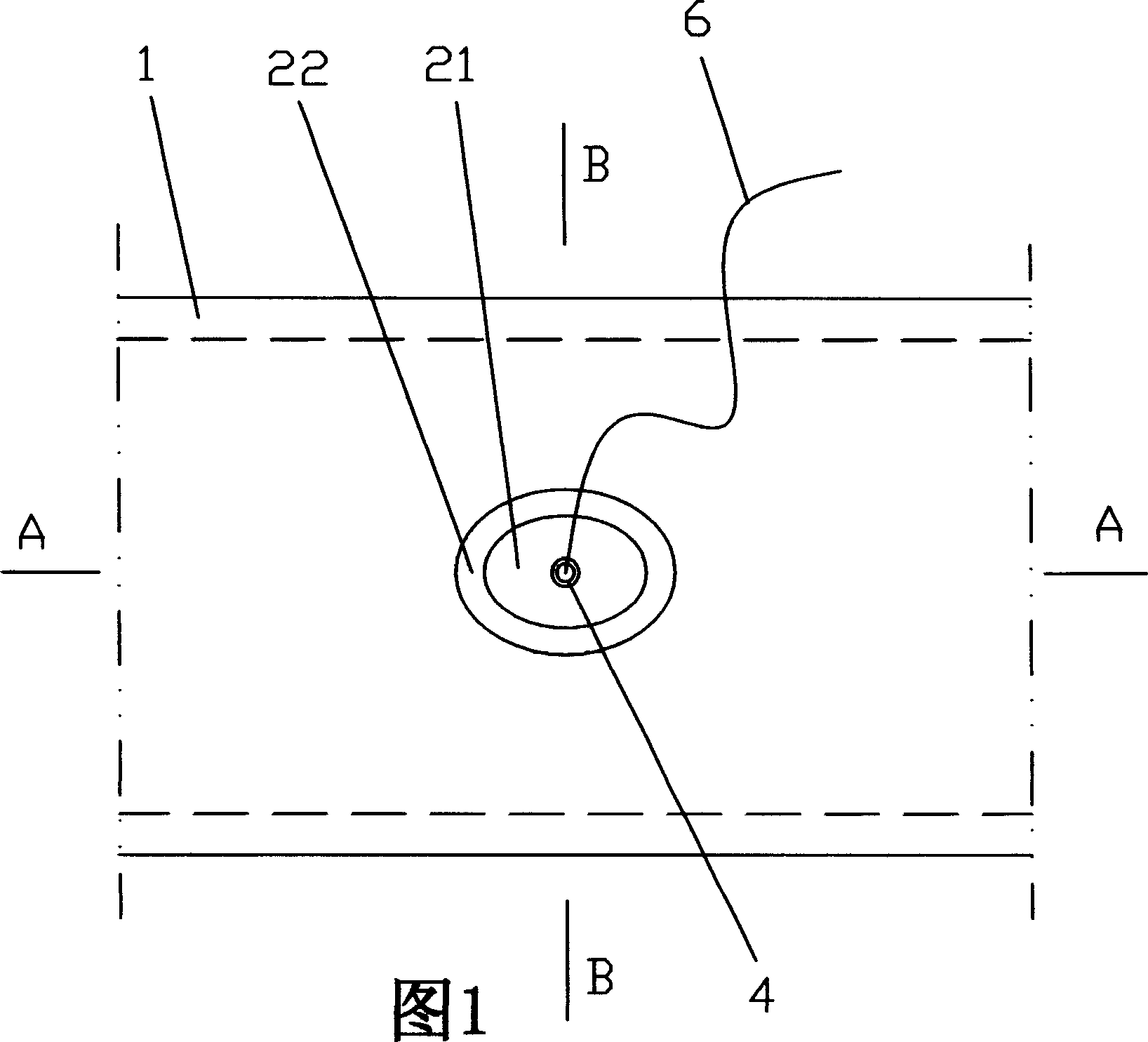

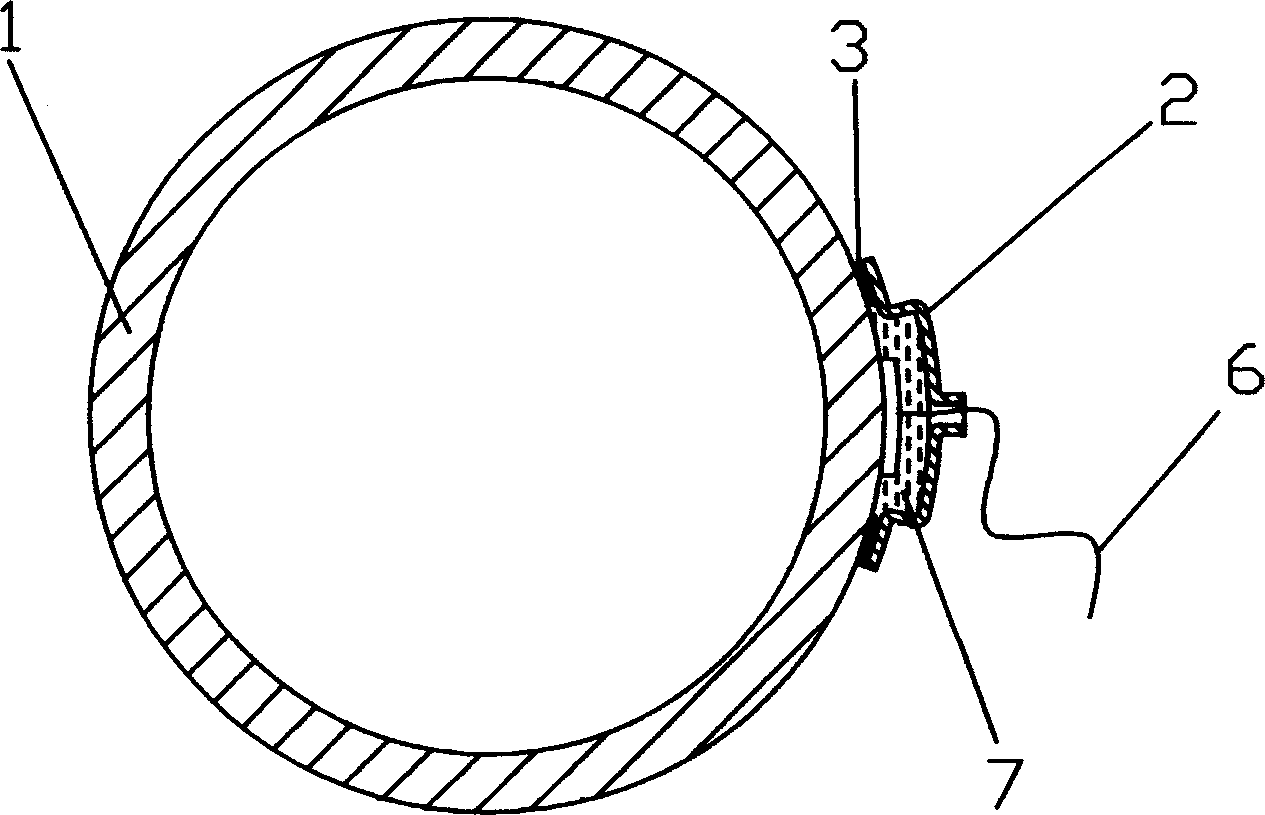

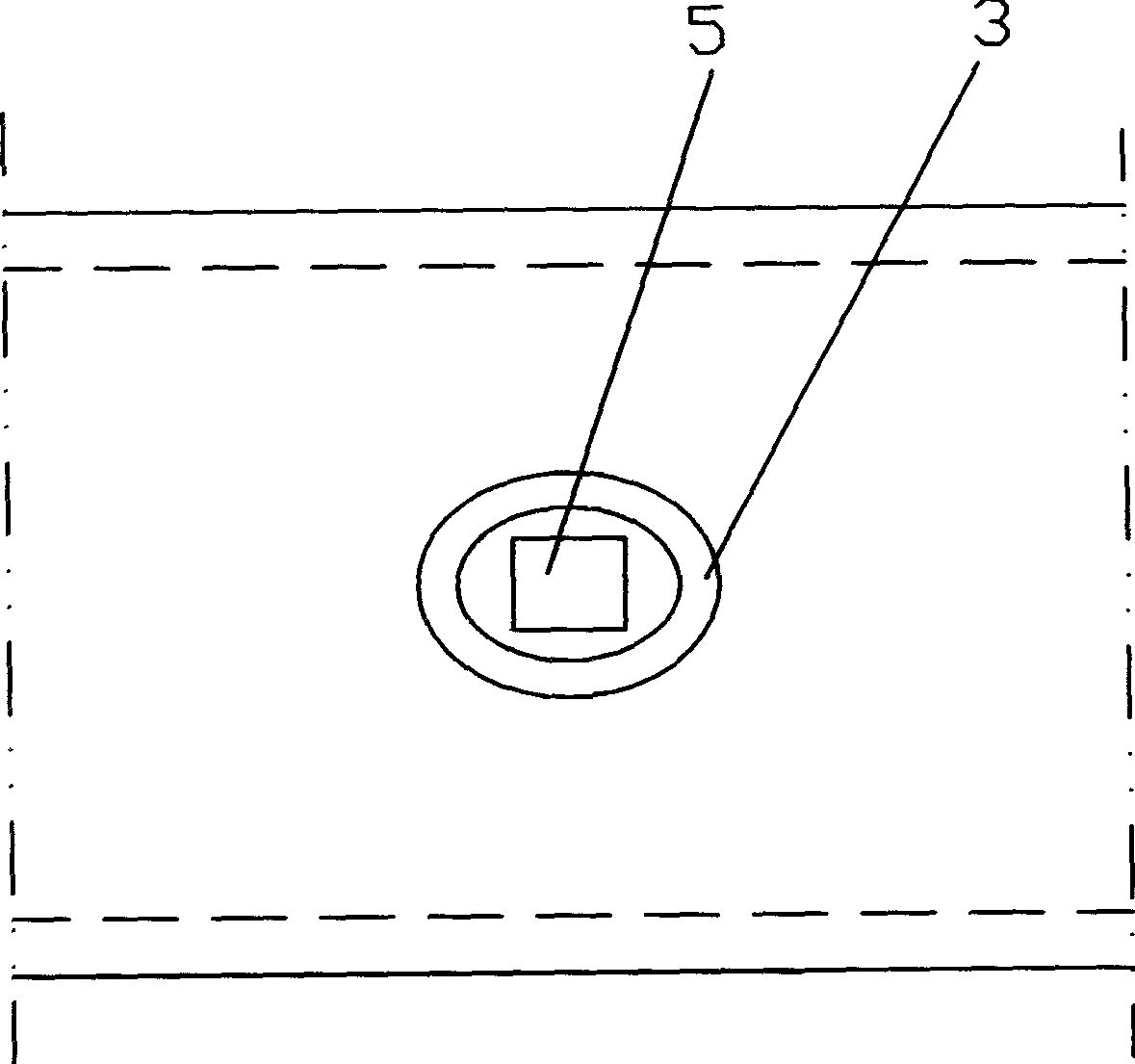

[0019] Figure 1 is a schematic diagram of a thin metal cover brazed on an offshore platform conduit. Part 1 is the conduit of the offshore platform, and Part 2 is a cover made of thin copper sheet. The thin copper cover includes a cover top 21 and a cover edge 22. The top of the cover is provided with a wire joint outlet 4. The shape of the bottom of the cover edge 22 is consistent with that of the offshore platform. The arc shape of the conduit 1 is adapted, and the bottom of the edge 22 of the cover is pre-coated with flux and covered with solder 3 . Such as figure 2 As shown, the strain gauge 5 is pasted on the conduit wall, and the periphery of the strain gauge is coated and covered with flux and solder. same. Fig. 3 is a sectional view along A-A in Fig. 1, Figure 4 It is a cross-sectional view along B-B in Fig. 1. The joint of wire 6 and the strain gauge are connected by general brazing, and the wire 6 passes through the outlet 4 of the wire joint of the cover 2. When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com