Three stage temperature control method for preparing compost

A technology of temperature control and composting, which is applied in the field of fermented organic fertilizers, can solve problems such as complexity, increased composting costs, and threats to dominant positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

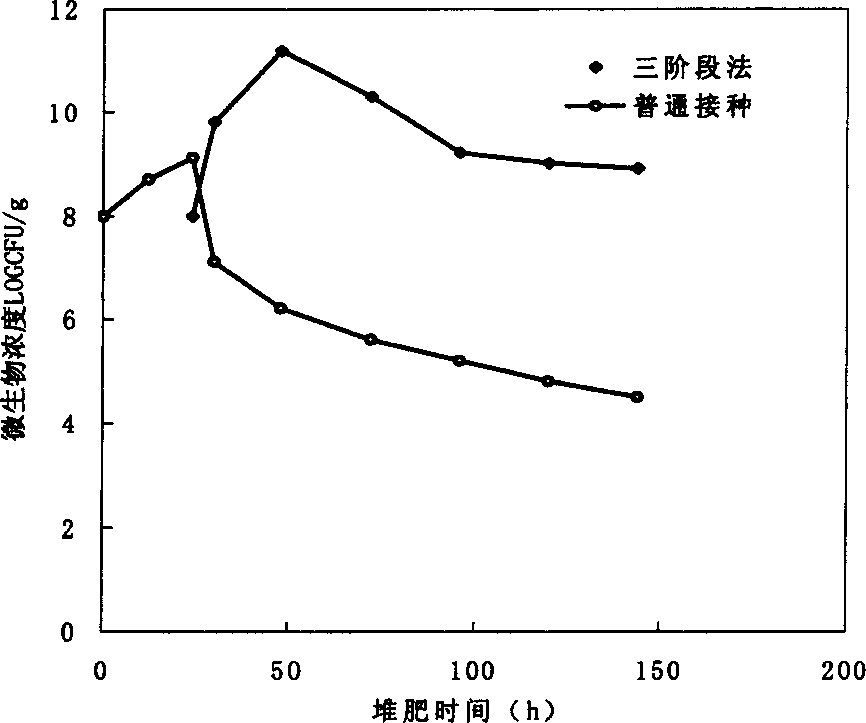

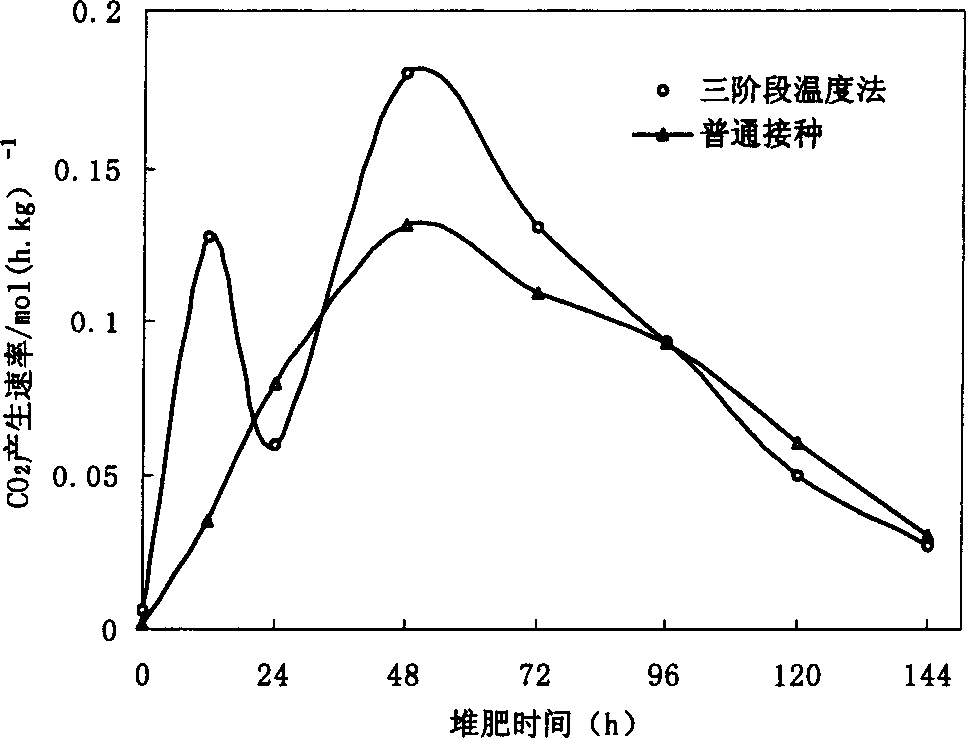

[0013] Collect each 10kg of fresh rubbish, rubbish water content 60%, C / N=25, organic matter content 60%; Garbage is packed into compost reactor, ventilated (0.5L / (min / kg), and open reactor heater, make The temperature rises above 75°C within 4 hours and is maintained for 8 hours. After cooling, add 0.5% compound microbial agent to carry out natural fermentation, and measure the microbial changes and CO production during the composting process. 2 gas volume.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com