Oxygen gun repairing device

An oxygen lance and repair room technology, applied in the direction of manufacturing converters, etc., can solve the problems that the outer tube and the middle tube cannot be replaced, the steelmaking plant is difficult to implement, and the floor area is large, achieving low cost, easy manufacturing, and convenient maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

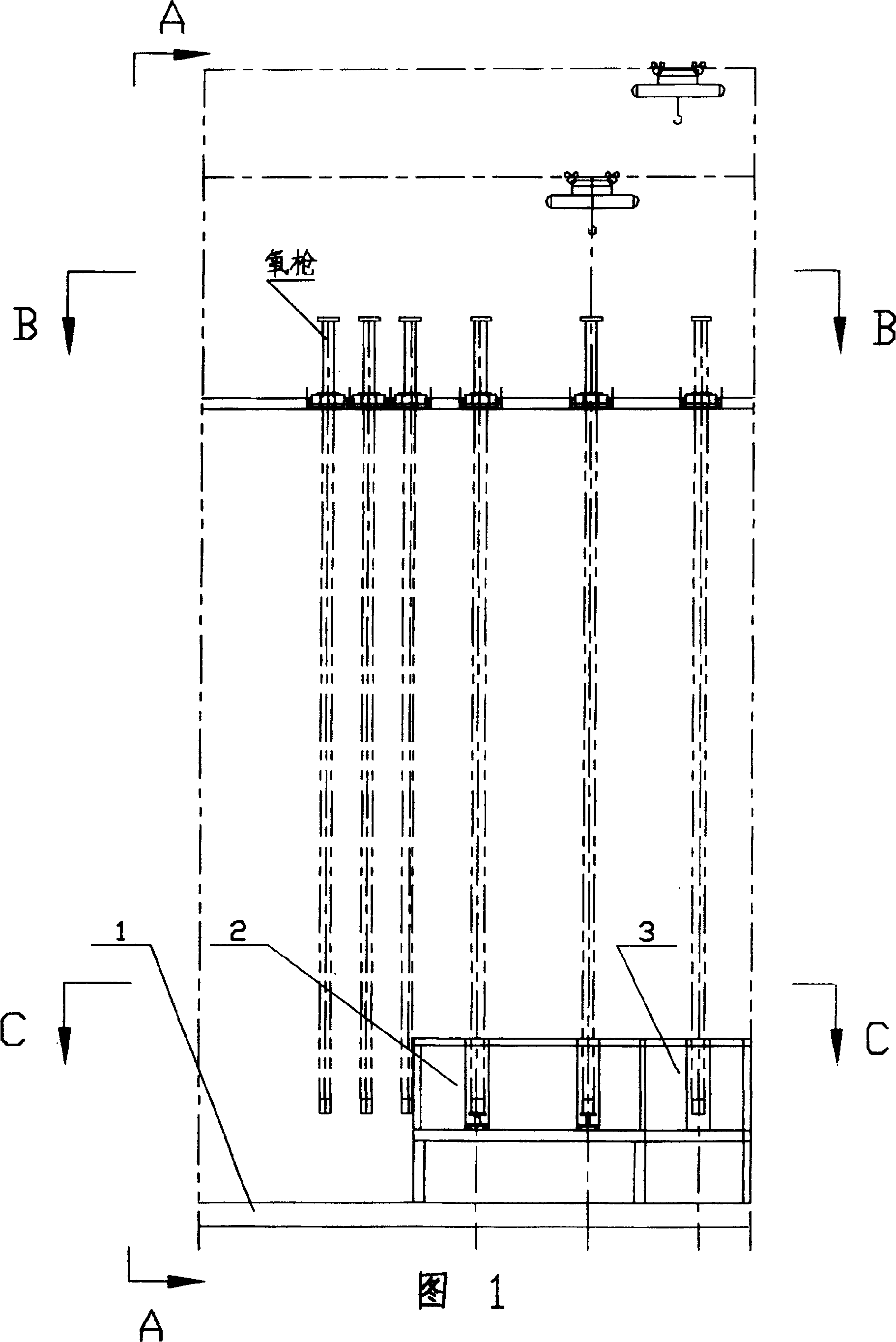

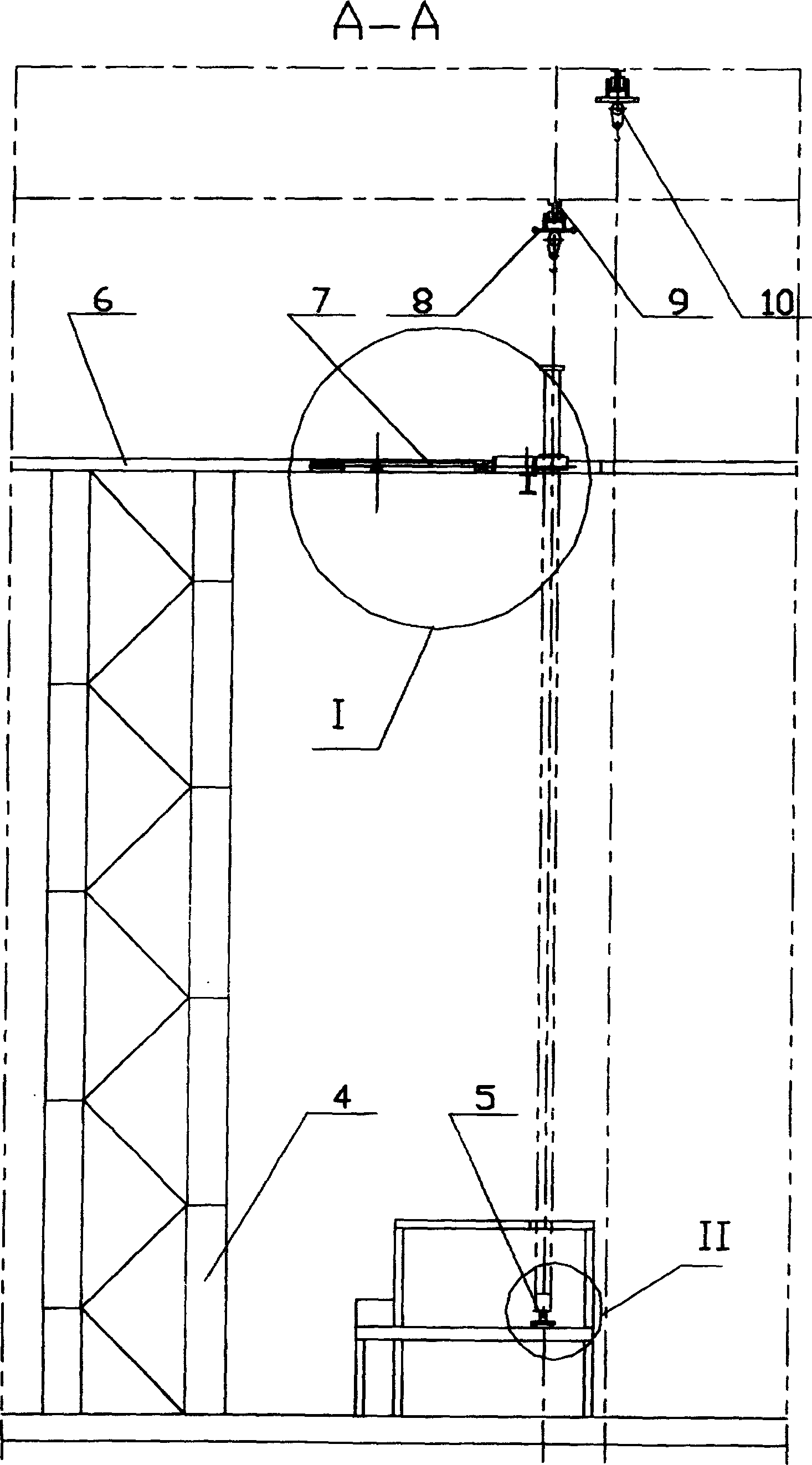

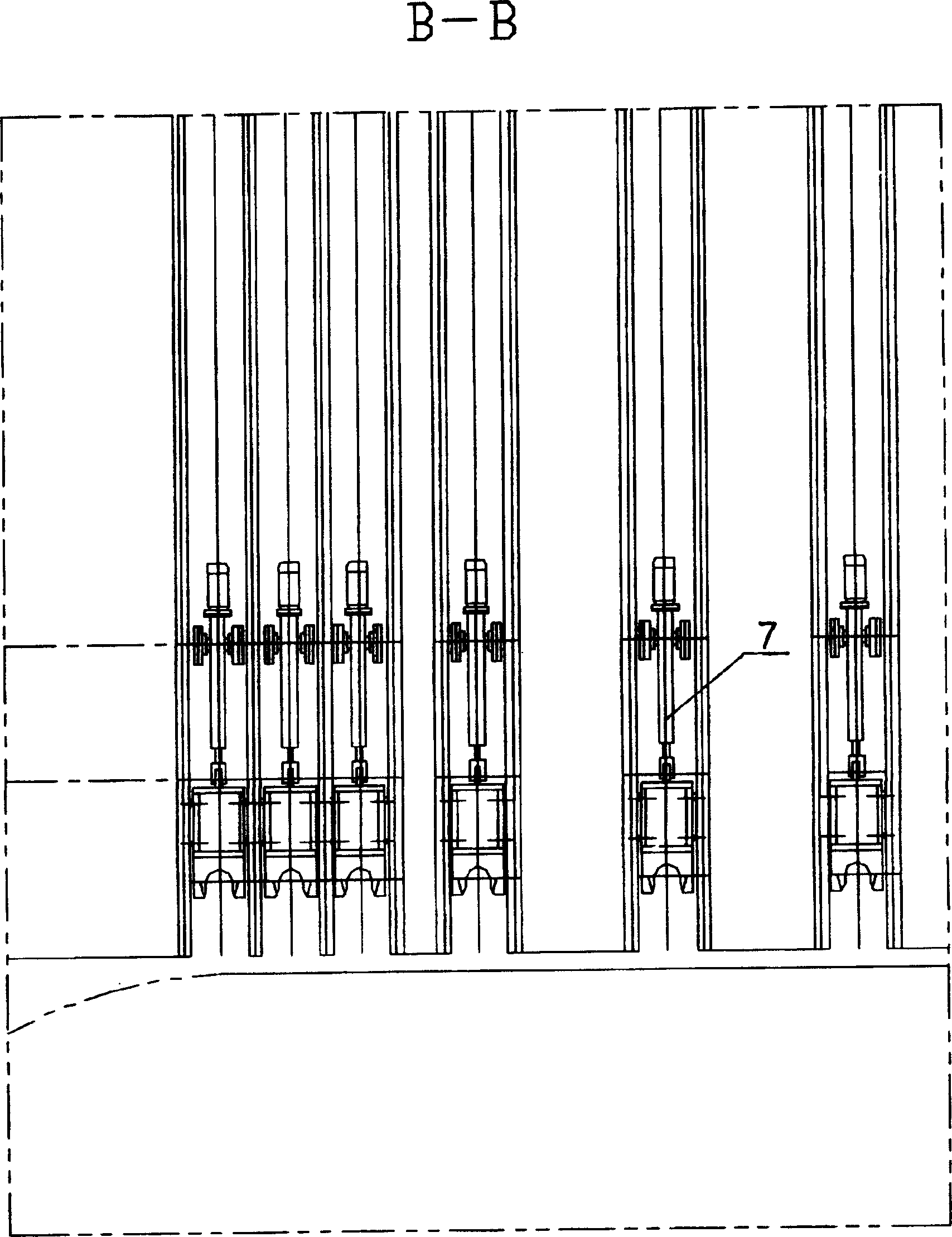

[0017] Figure 1, figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, the oxygen lance repair device consists of lower platform 1, repair room 2, slag cleaning room 3, escalator 4, lifting platform 5, upper platform 6, electro-hydraulic push rod driven trolley 7, lifting electric hoist 8, lifting I-beam 9. It is composed of walking electric hoist 10 and walking I-shaped steel beam 11. The lower platform 1 and the upper platform 6 are welded steel structures, and the four corners are connected with workshop columns. The lower platform 1 is installed with the repair room 2 and the slag cleaning room 3, and the upper platform 6 is equipped with 6 electro-hydraulic push rod-driven trolleys 7, and the oxygen lance repair personnel can test the repaired oxygen lance on the upper platform 6. The escalator 4 is welded by steel structure, the top is connected with the upper platform 6, and the bottom is connected with the lower platform 1. The oxygen lance repair perso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com