Absolute pressure type pressure sensor

A pressure sensor, absolute pressure technology, applied in the direction of measuring fluid pressure, measuring fluid pressure through electromagnetic components, instruments, etc., can solve problems such as pressure sensor installation defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

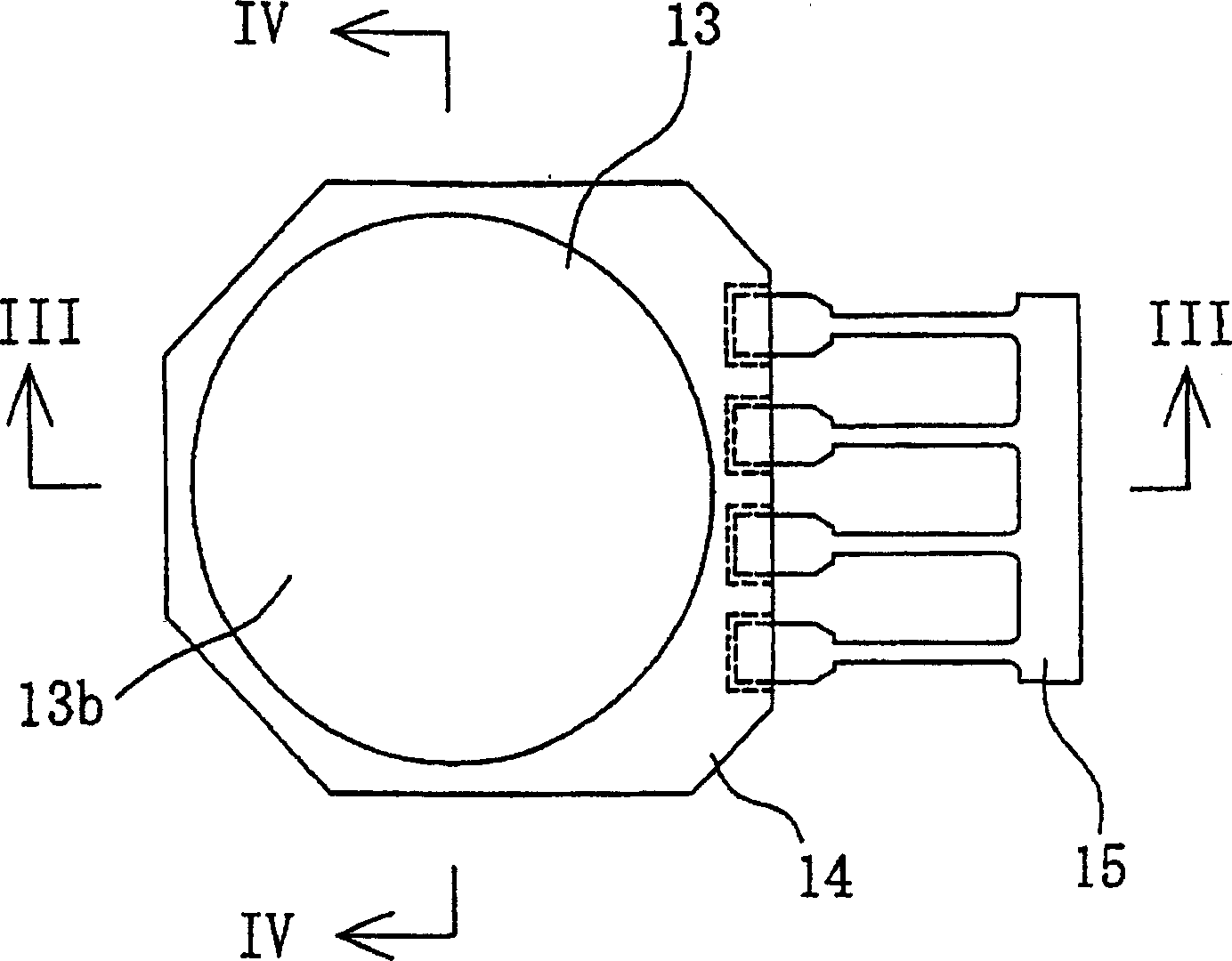

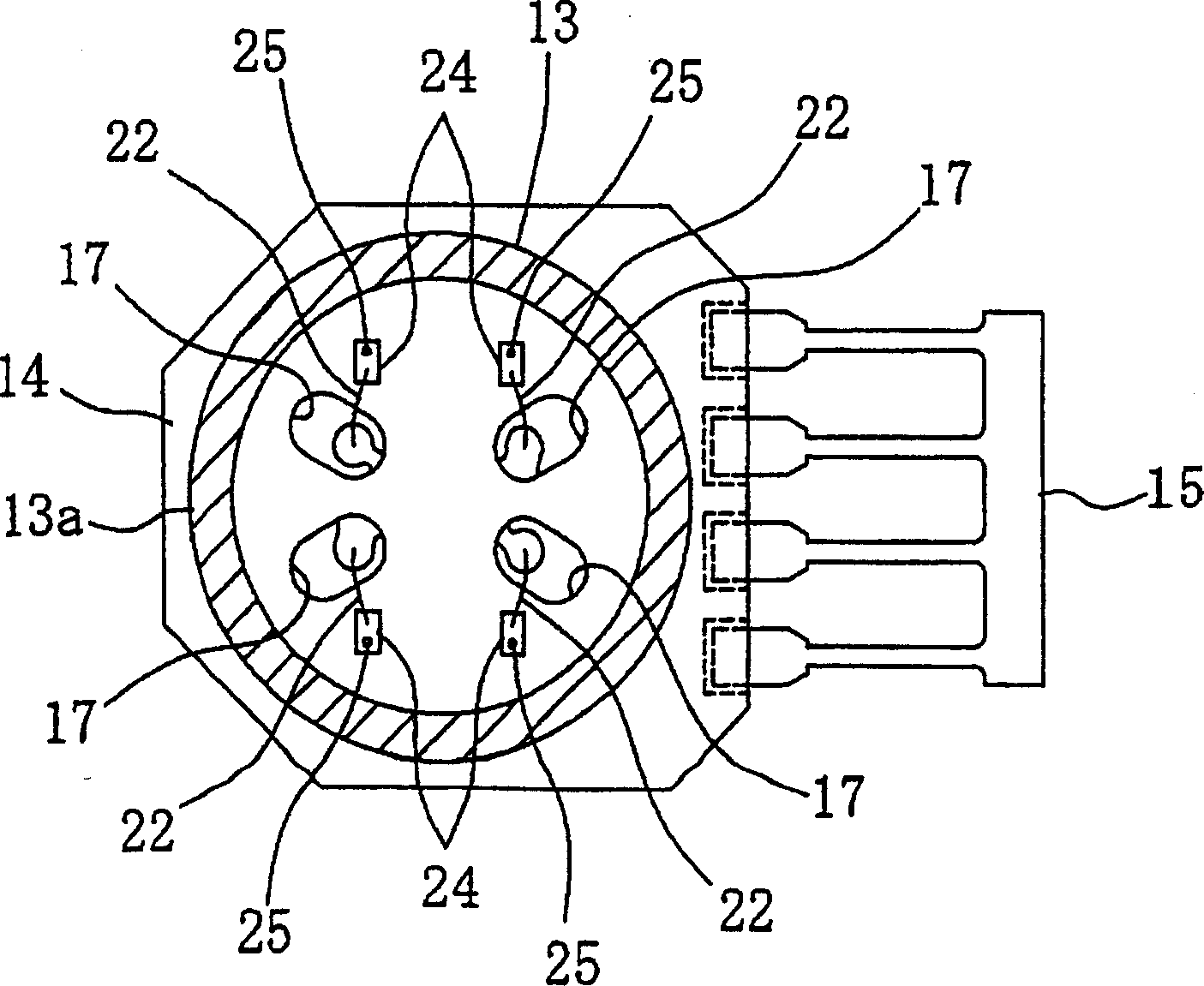

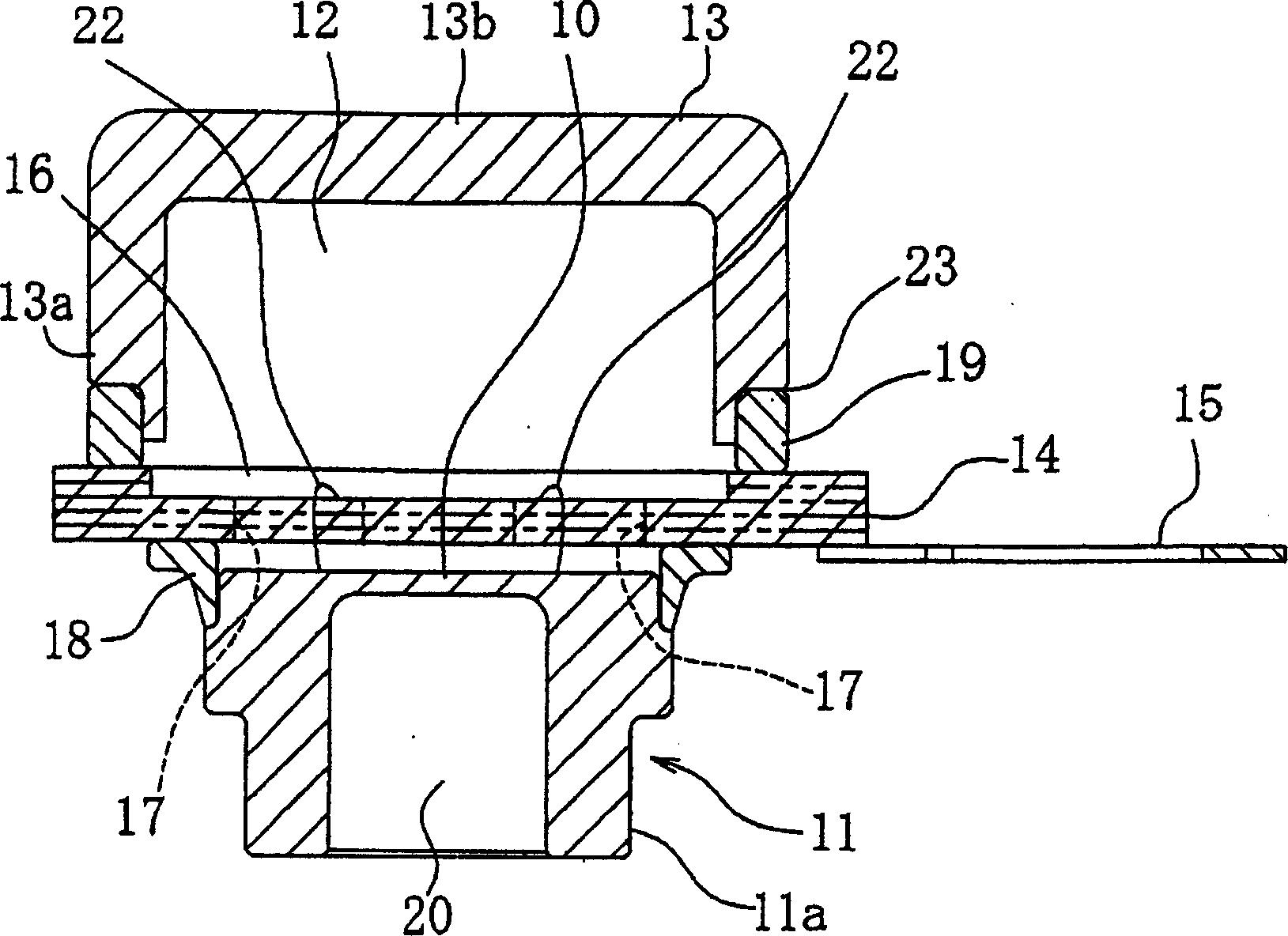

[0032] refer to Figures 1 to 4 , the first embodiment of the absolute pressure type pressure sensor will be described below.

[0033] This absolute pressure type pressure sensor has a pressure measuring device 11 , a metal cover 13 , a relay board 14 and an input / output terminal 15 .

[0034] like image 3 and 4 As shown, among these members, the pressure measuring device 11 has a cylindrical part 11a with a metal film 10, and a strain gauge 9 is installed on one surface of the metal film 10 (such as Figure 10 as shown). The face on which the strain gauge is mounted is located on the side of the cylindrical member 11a opposite to the fluid introduction port 20 formed by the surface of the opposite side of the cylindrical member 11a. A metal cover 13 is provided to form a reference pressure space 12 surrounding the strain gauge 9 placed on the metal membrane 10 . The relay plate 14 is electrically connected not only to the strain gauges 9 but also to the I / O terminals 15...

no. 2 approach

[0053] refer to Figures 5 to 8 , an absolute pressure type pressure sensor according to a second embodiment of the present invention will be described below.

[0054] The absolute pressure type pressure sensor in this embodiment is equipped with a relay board 26 different from that in the first embodiment. In particular, the relay board 26 is not provided with a cavity on the relay board 14 as in the first embodiment. Therefore, both surfaces of the relay board 26 are flat, so that its manufacturing process can be simplified compared with that of the relay board 14 in the first embodiment.

[0055] Other components and production are completely consistent with those in the first embodiment, and the reference numerals shown are also the same as those in the first embodiment, and their detailed descriptions are omitted here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com