Method and apparatus for measuring vector distance on lead wire connector

A technology of wire bonding and bonding head, which is applied in the field of devices, and can solve problems such as the distance change between the capillary and the image recognition system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

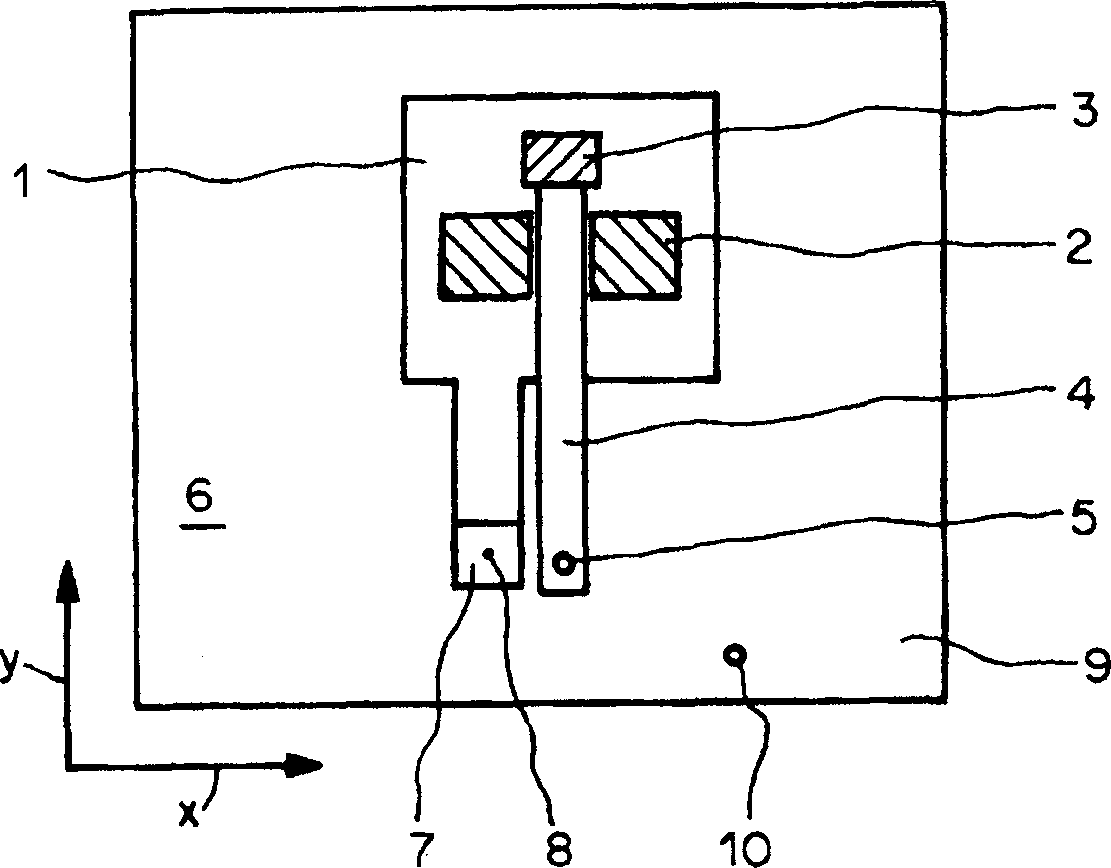

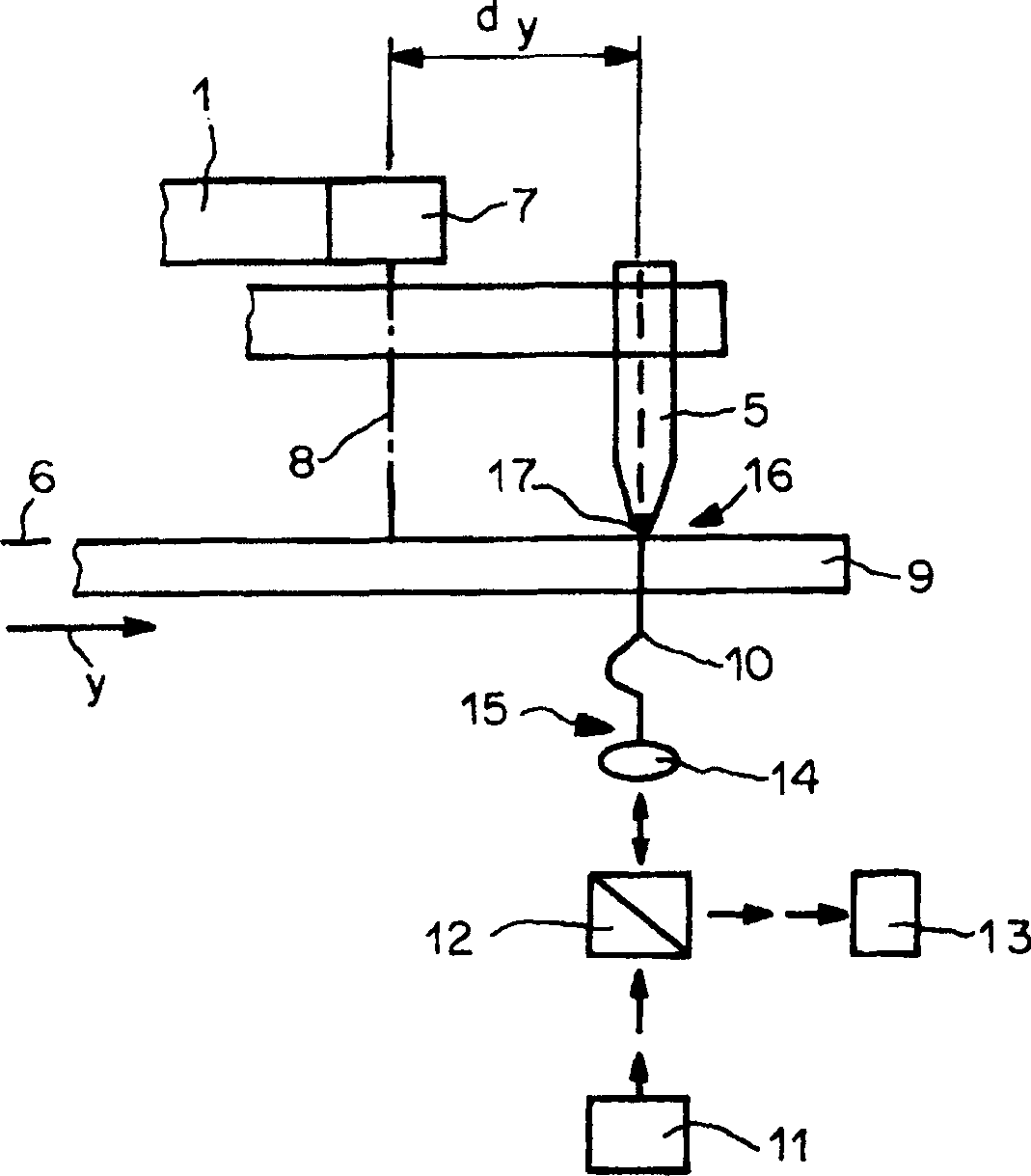

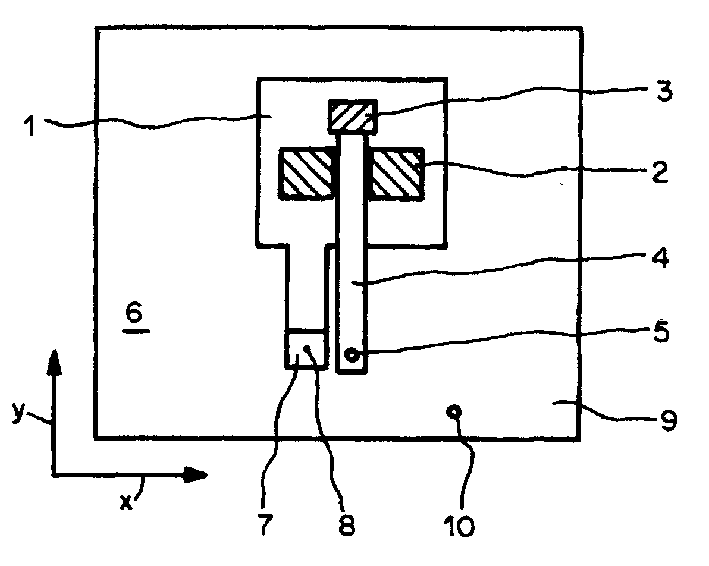

[0014] figure 1 A plan view of a bonding head 1 of a wire bonder is shown. The joint head 1 contains a rocker 2 that can rotate on a horizontal axis. An angle 4 is connected to the rocking rod 2, and the ultrasonic transducer 3 can apply ultrasonic waves to it. A capillary 5 is clamped at the tip of the horn 4 . The capillary 5 is used to fix the leads to the connection points on the semiconductor chip and to the designated connection points on the substrate, while guiding the wiring between the two connection points. The bonding head 1 can move the capillary 5 on a plane 6 determined by two coordinate axes x and y, and the rocker 2 can move the capillary in a direction perpendicular to the plane 6 . In addition, the wire bonder also includes an image recognition system with its observation area facing the plane 6 for measuring the position of the connection points on the semiconductor chip and the connection points on the substrate. The image recognition system includes a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com