Multiple filament parallel lamp

A filament and main filament technology, applied in the direction of discharge lamps, lamp circuit components, fixtures/supports of illuminants, etc., can solve the problem of reducing the impedance of the current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

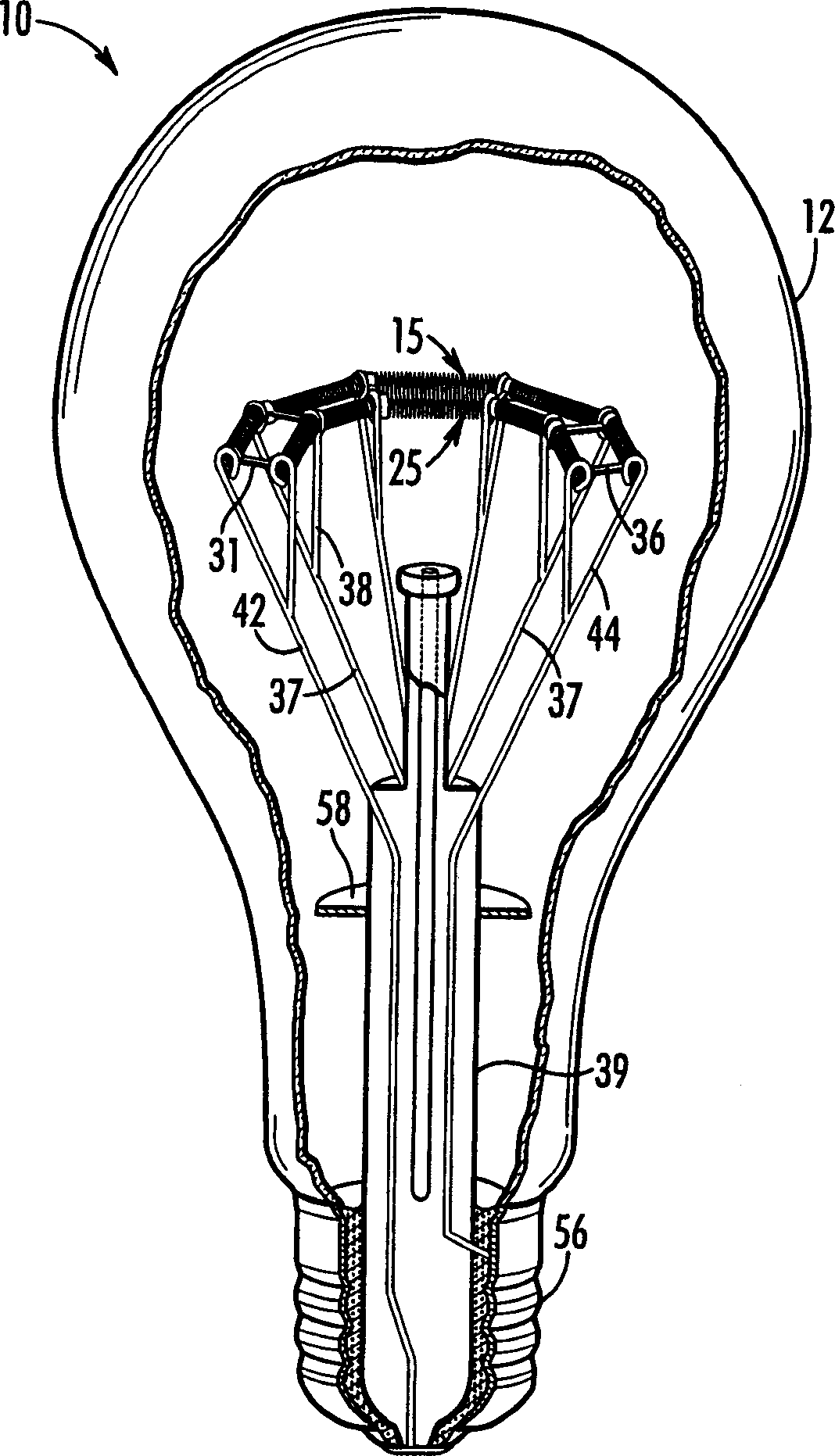

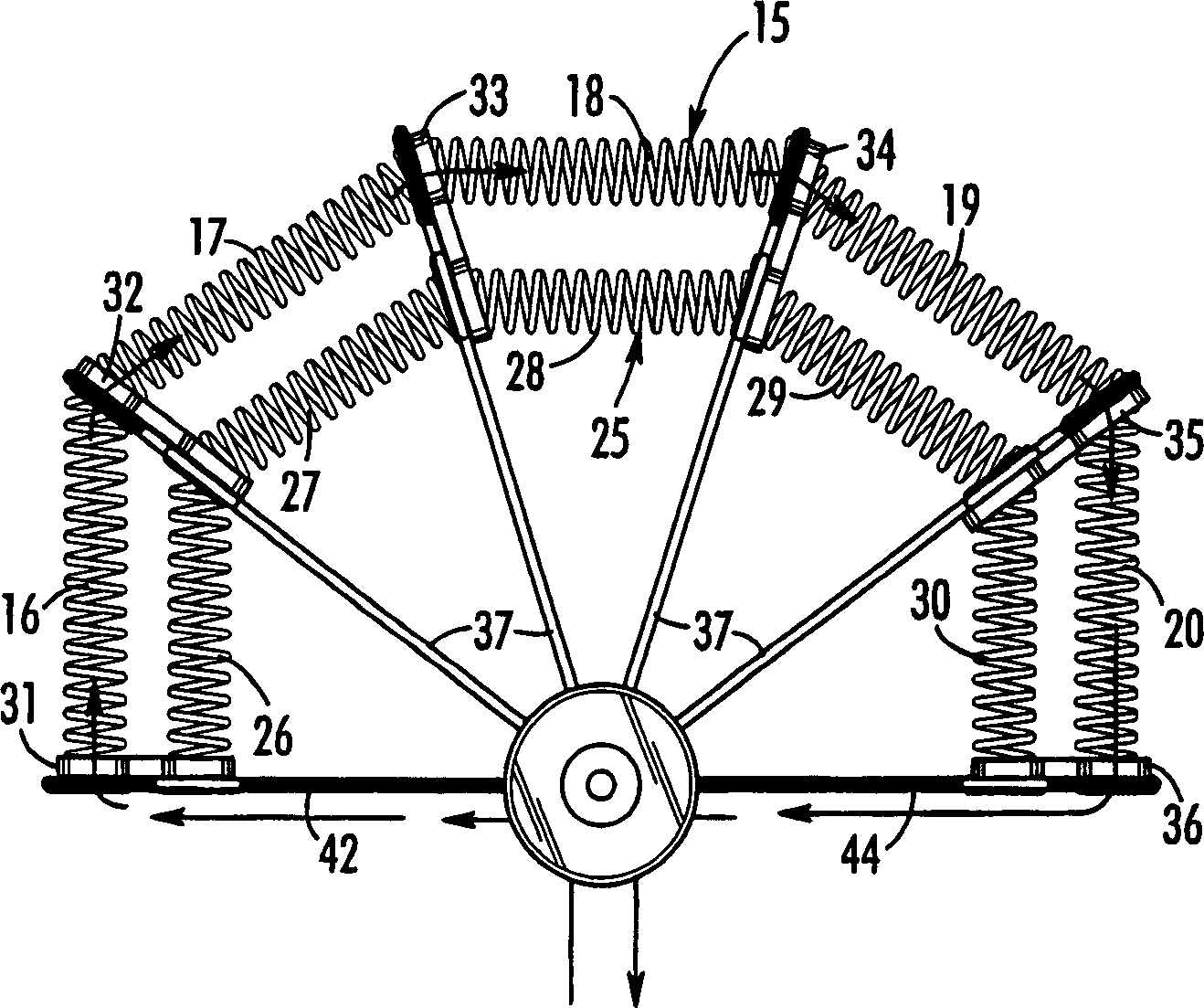

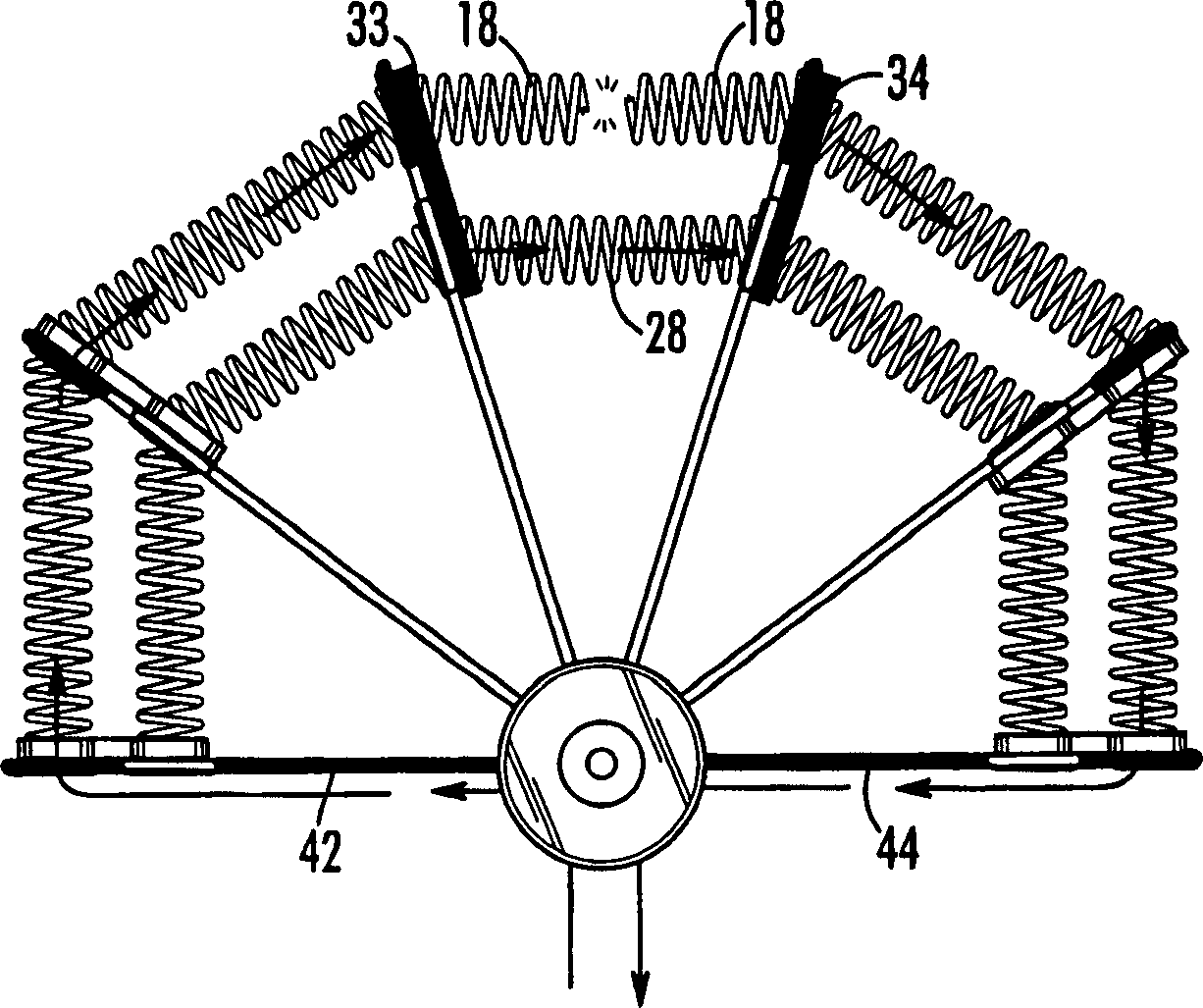

[0016] The present invention is an improvement to electric lamps, which is mainly aimed at, but not limited to, prolonging the service life of incandescent lamps. In particular, the improvement includes the use of a spare filament (or filament section) to replace a broken main filament section, and the use of a bypass shunt to automatically alter the normal current path, ie, through the main filament section, to energize the spare filament. This improvement will significantly extend the operating life of the lamp due to the use of each additional filament segment and / or set of spare filament segments, while still maintaining a high visible light emissivity. Additionally, because the lamp changes are incorporated into the interior of the lamp, the improved lamp of the present invention can be inserted into any existing lamp socket.

[0017] figure 1 and 3An embodiment of a lamp of the present invention is shown, generally designated by the reference numeral 10, having a prima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com