Shift forming method for double curved glass tempering procedure

A technology of glass tempering and forming method, applied in glass forming, glass remolding, glass tempering and other directions, can solve the problems of difficulty in producing deep-bent tempered glass, high manufacturing cost of vacuum suction cups, affecting glass forming effect, etc. Improve the molding effect and yield, low production cost and use cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In conjunction with accompanying drawing, provide embodiment of the present invention as follows:

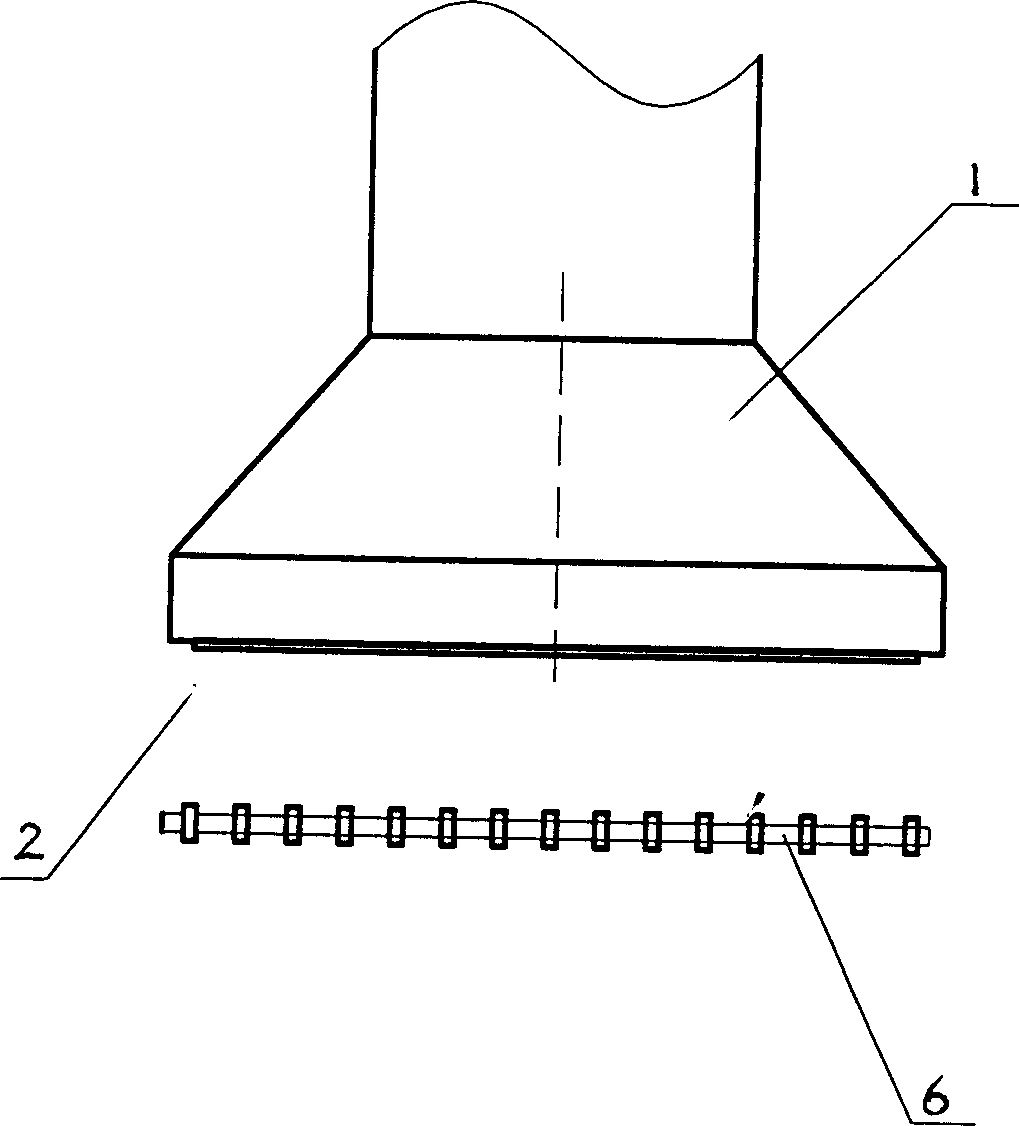

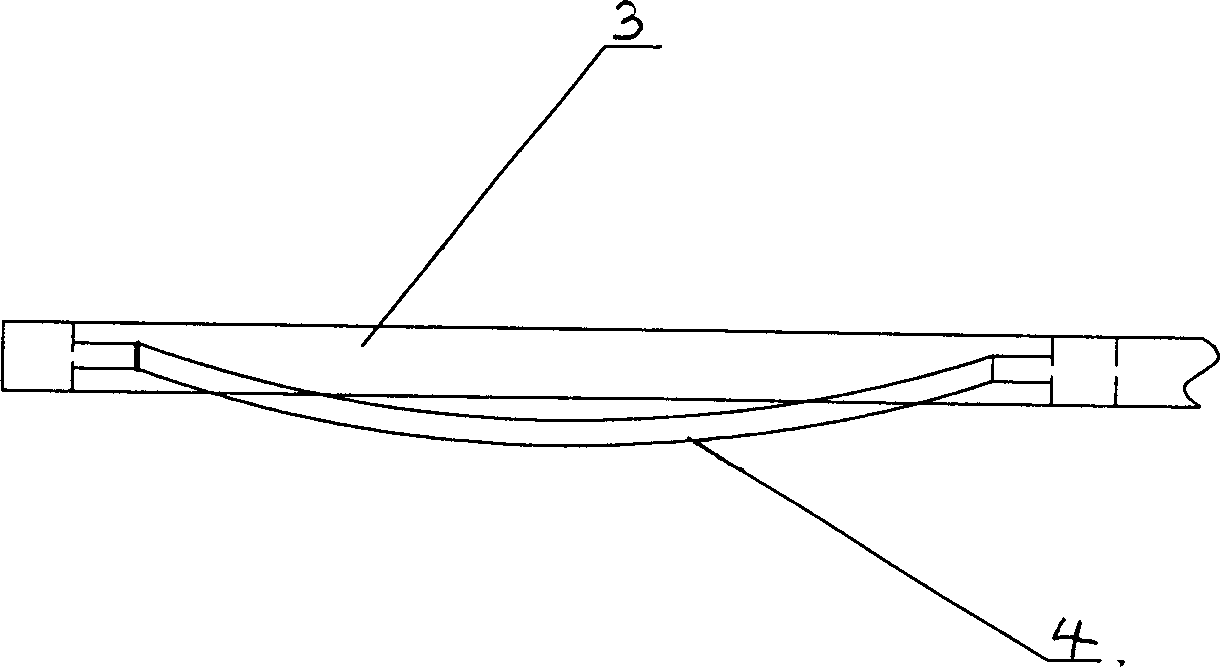

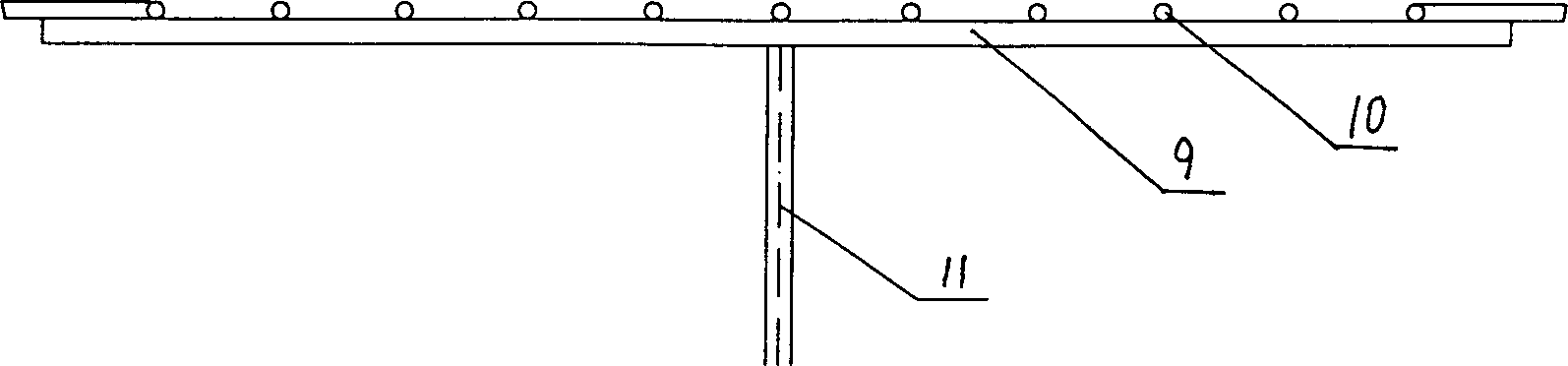

[0018] as attached Figure 6-7 As shown, in this embodiment, a hidden lifting device is provided on the transmission roller table 6 of the existing horizontal roller table type hyperboloid tempering electric furnace. The transmission roller table 6 is made up of a plurality of transmission shafts 7 and a plurality of transmission wheels 8 sleeved on the transmission shafts 7. In order to reduce heat loss, the transmission wheels 8 are made of non-metal high temperature resistant materials. Lifting device (as shown in Figure 34) is made up of large bracket 9, small support arm 10 and elevating rod 11, and the center of elevating rod 11 and large bracket 9 is fixedly connected, and small support arm 10 has many, each small support arm The centers of the arms 10 are all fixedly connected with the large bracket 9 to form a liftable bracket structure. The large bracket 9, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com