Railroad switch tamping tool quick-speed removable horizontal swinging type dual hydraulic rail clampping apparatus

A technology of horizontal swing and tamping machine, which is applied in the directions of roads, tracks, ballast layers, etc., can solve the problems such as the inability to carry out the tamping operation of the turnout, the inability to realize the switch part of the turnout rail or the rail clamping of the frog part, etc. The effect of large clamping force, balanced insertion resistance and high tamping quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Implementation process and action principle of the present invention are:

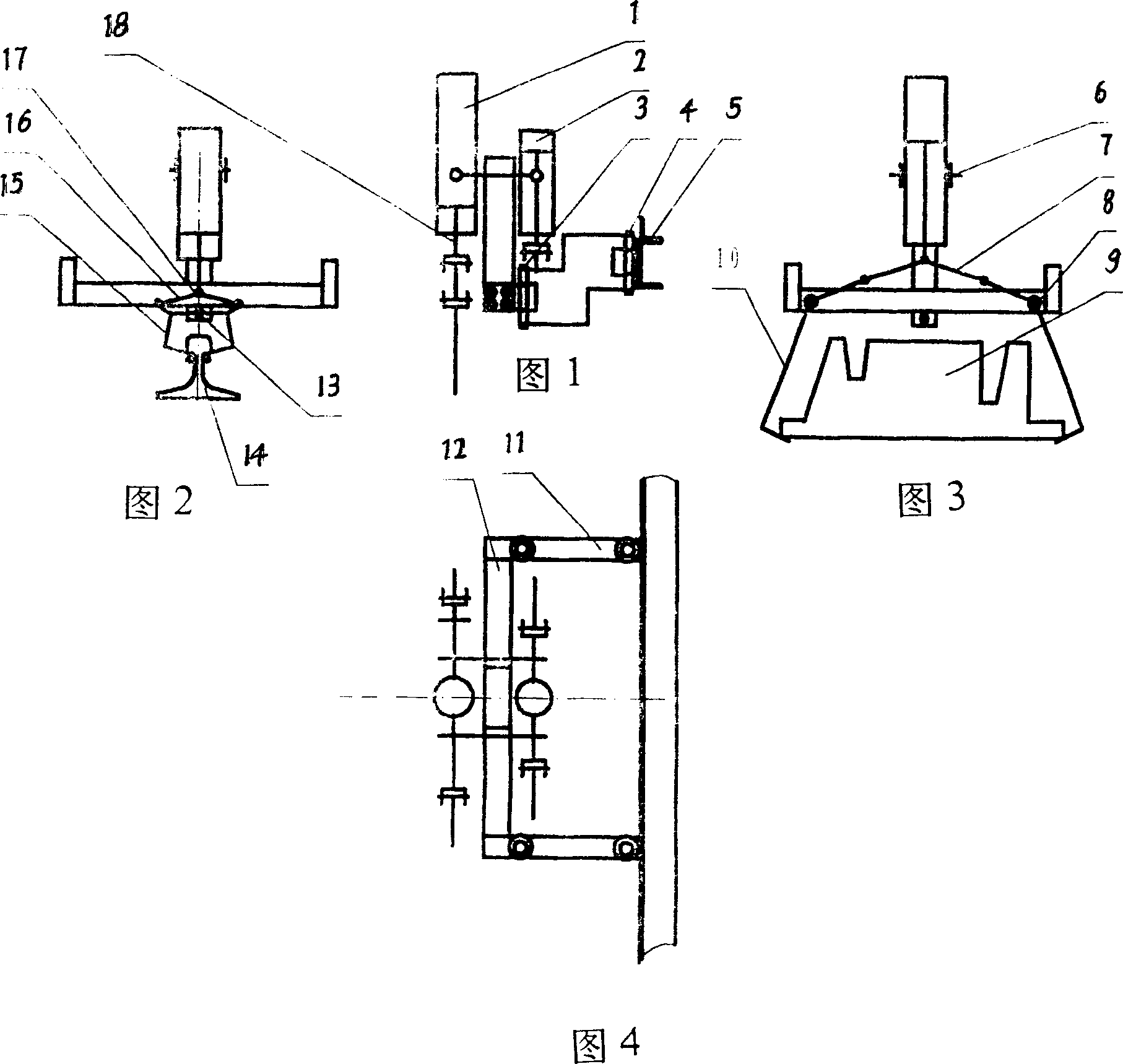

[0023] Each set of fast detachable horizontal swing double hydraulic rail clamping device is composed of a large clamp cylinder 1 and two large clamp clamps 10, a small clamp cylinder 2 and two small clamp clamps 15. The large and small rail clamps can be operated separately under the action of the large and small clamp cylinders. The hydraulic oil of the large and small clamp cylinders is respectively supplied by two reversing valves. The handle, the big clamp moves accordingly; when the small clamp is needed to clamp the rail, move the small clamp handle of the reversing valve, the small clamp moves accordingly, and the large and small clamps can also move at the same time.

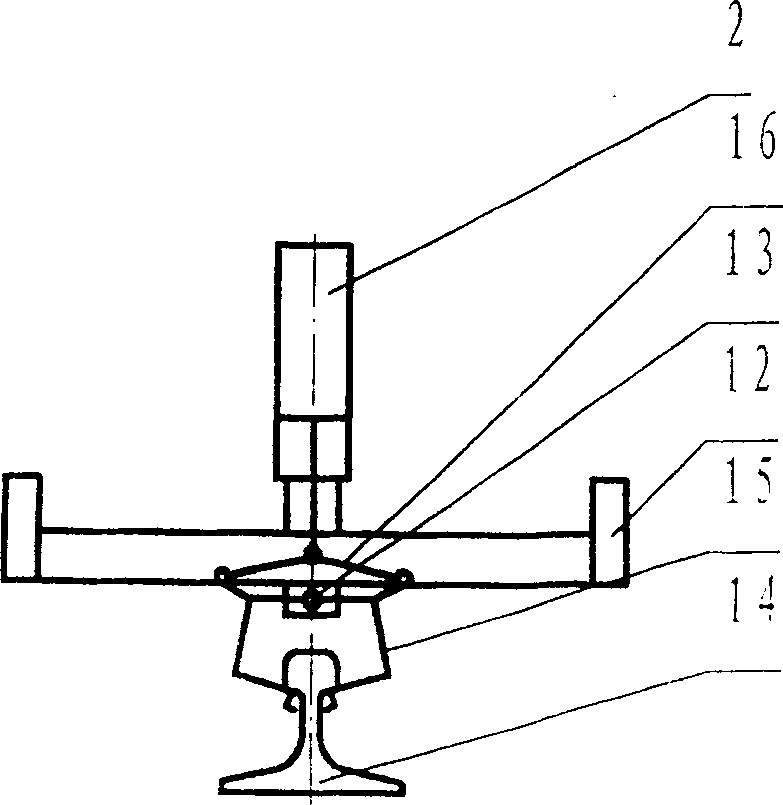

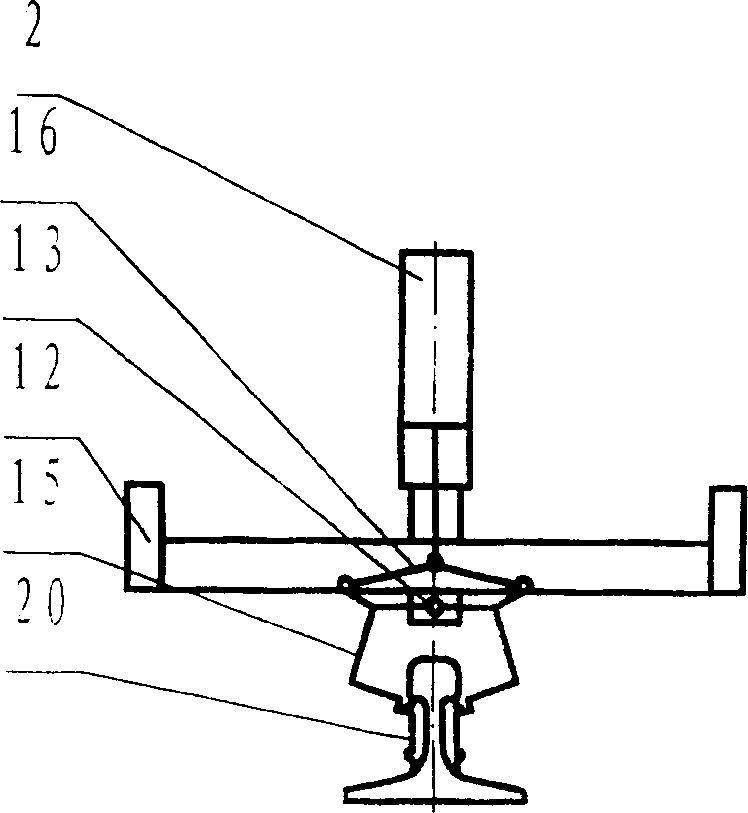

[0024] Action principle of the small rail clamp: see Figure 5 , Figure 6 .

[0025] When needing small clamp 15 clamp rails, move reversing valve small clamp handle, hydraulic oil enters small clamp oil cylinder 2 up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com