Method for producing Chinese wolfberry liquor

A production method and technology for wolfberry wine are applied in the production field of wolfberry wine, and can solve the problems of incomplete extraction of effective components, long aging period, bitter taste of wolfberry wine and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

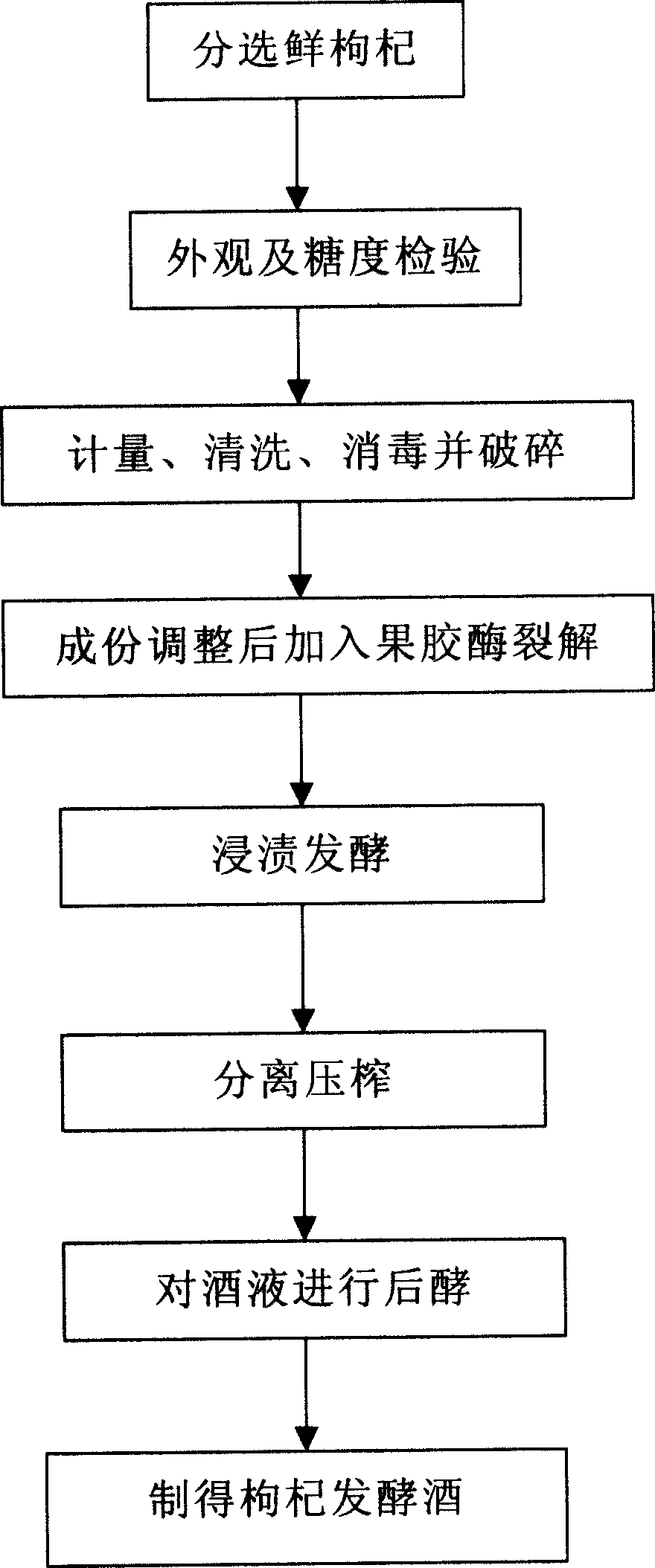

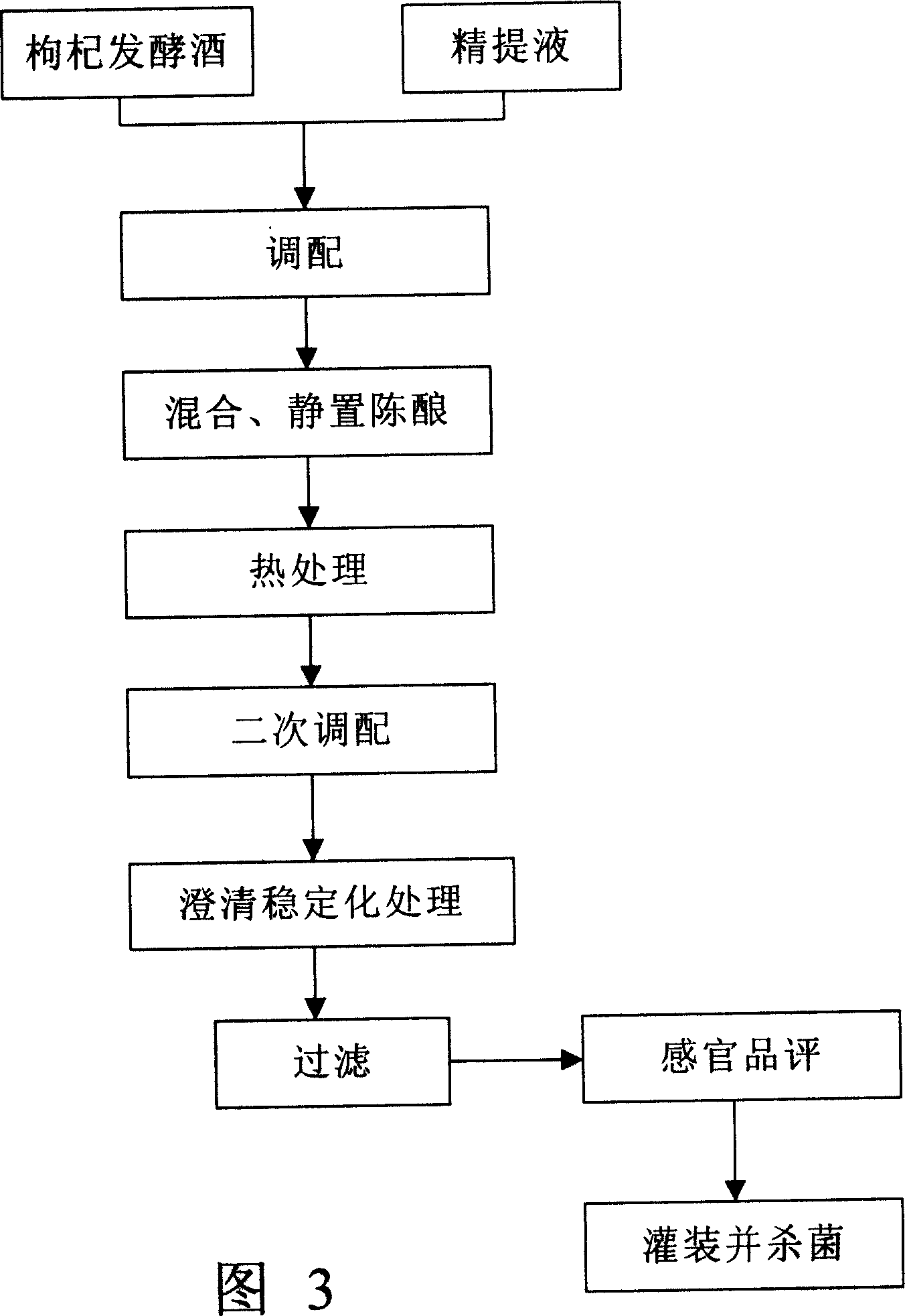

[0036] 700kg of fresh goji berries picked on the same day were sorted to remove mildew and rotten fruits. After passing the appearance and sugar content inspection, they were accurately weighed and measured, and cleaned with 0.3% CLO 2 Soak in the solution for 15 minutes to remove pesticide residues and kill bacteria. Crushed by a beater until the diameter of the pulp is about 2mm, put it into the tank, add 0.7L sulfurous acid, 46kg of deodorized alcohol to adjust the ingredients, add 35kg of white sugar and pour it into the tank for 1 hour, add 70g of activated pectinase and pour it into the tank for 1 hour, and finally add the activated pectinase 0.35kg of special yeast liquid was poured into the tank for 1 hour, soaked and fermented, the pre-fermentation temperature was 18°C, and the fermentation time was 9 days. The fermentation status was tested and analyzed every day. When the residual sugar was less than 4g / l, it was separated and squeezed with an air film press. After ...

Embodiment 2

[0057] 700kg of fresh goji berries picked on the same day were sorted to remove mildew and rotten fruits. After passing the appearance and sugar content inspection, they were accurately weighed and measured, and cleaned with 0.3% CLO 2 Soak in the solution for 15 minutes to remove pesticide residues and kill bacteria. Crushed by a beater until the diameter of the pulp is about 3mm, put it into the tank, add 0.7L sulfurous acid, 46kg deodorized alcohol to adjust the ingredients, add 35kg white sugar and pour the tank for 1 hour, add 105g activated pectinase and pour the tank for 1 hour, and finally add the activated pectinase 0.42kg of special yeast liquid was poured into the tank for 1 hour, soaked and fermented, the temperature of the pre-fermentation was 20°C, and the fermentation time was 7 days. The fermentation status was tested and analyzed every day. When the residual sugar was less than 4g / l, it was separated and squeezed with a film press, After the artesian wine and ...

Embodiment 3

[0078] 700kg of fresh goji berries picked on the same day were sorted to remove mildew and rotten fruits. After passing the appearance and sugar content inspection, they were accurately weighed and measured, and cleaned with 0.3% CLO 2 Soak in the solution for 15 minutes to remove pesticide residues and kill bacteria. Crushed by a beater until the pulp diameter is about 4mm, put it into the tank, add 0.7L of sulfurous acid, 46kg of deodorized alcohol to adjust the ingredients, add 35kg of white sugar and pour it into the tank for 1 hour, add 140g of activated pectinase and pour it into the tank for 1 hour, and finally add the activated pectinase 0.56kg of special yeast liquid was poured into the tank for 1 hour, soaked and fermented, the pre-fermentation temperature was 24°C, and the fermentation time was 4 days. The fermentation status was tested and analyzed every day. When the residual sugar was less than 4g / l, it was separated and squeezed with a film press, After the arte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com