Variable capacity rotary compressor

A rotary compressor and compressor technology, which can be used in rotary piston machinery, rotary piston pumps, rotary piston/swing piston pump components, etc., can solve the difficulties of variable capacity rotary compressors, increase the availability Problems such as production cost of variable capacity rotary compressor and complex structure of blade inertia component 5

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, preferred embodiments of the present invention will be described in detail, and these examples are shown in the accompanying drawings, in which the same reference numerals denote the same components throughout the text. To illustrate the present invention, reference will be made below

[0021] The drawings describe embodiments.

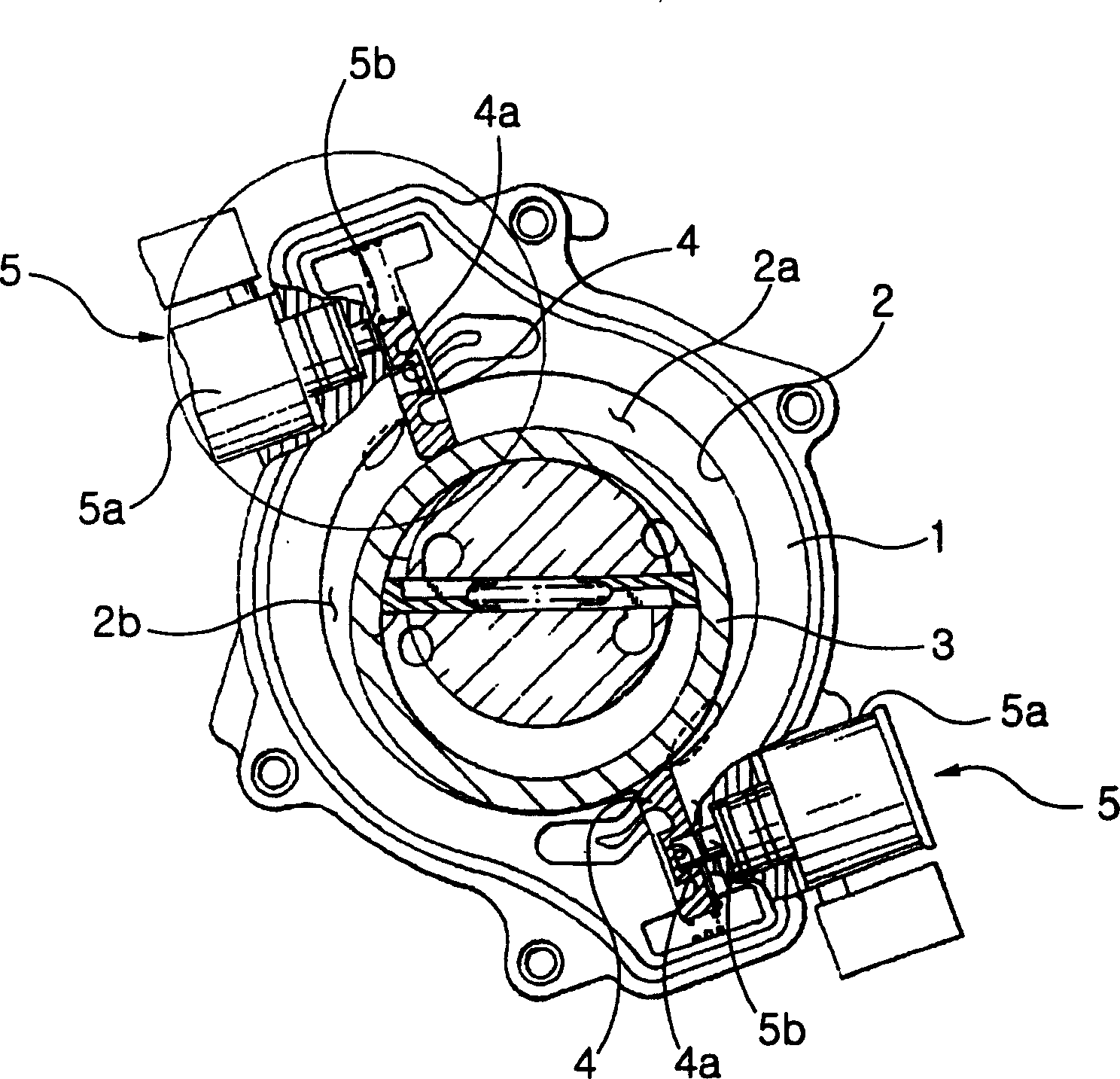

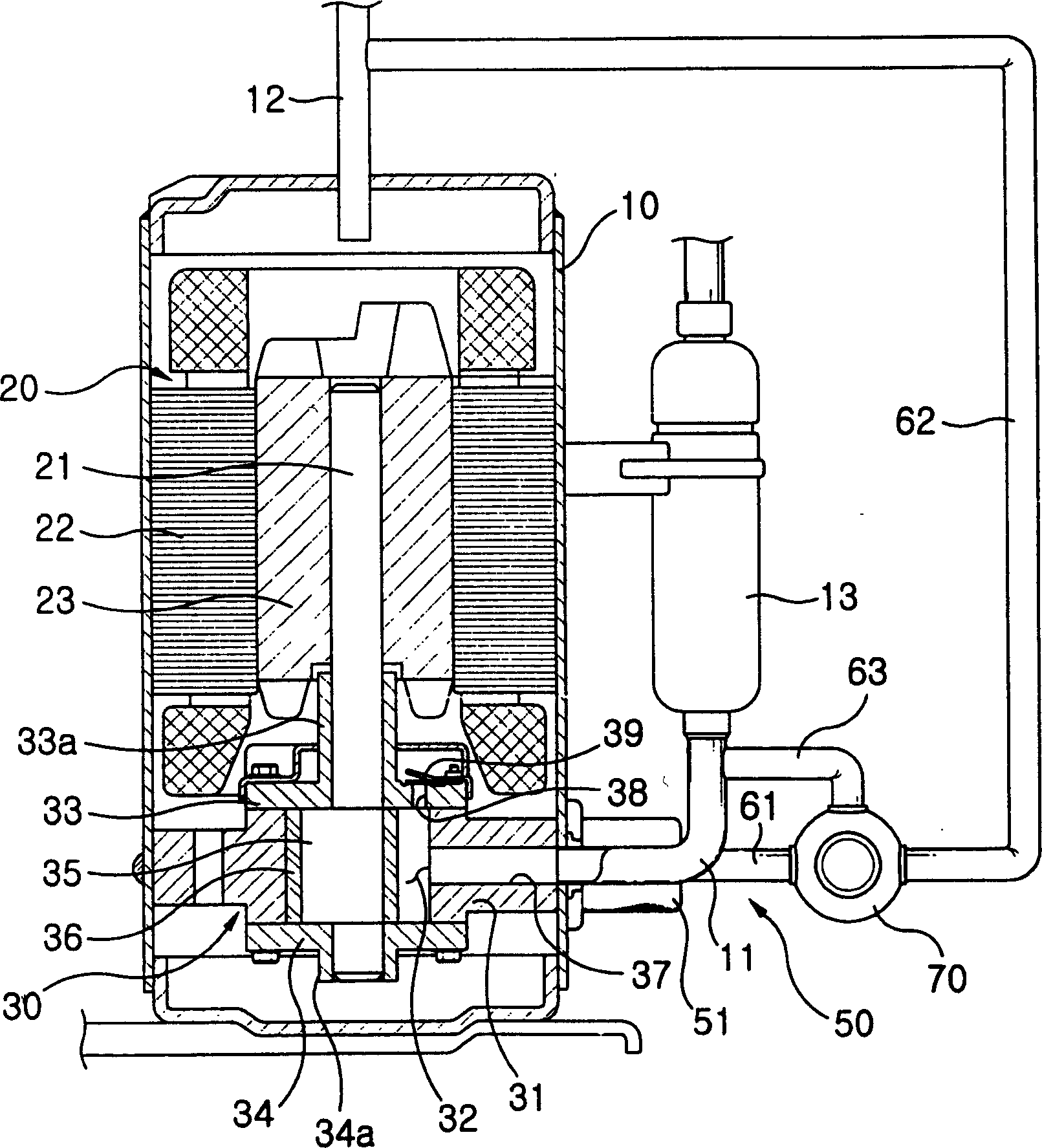

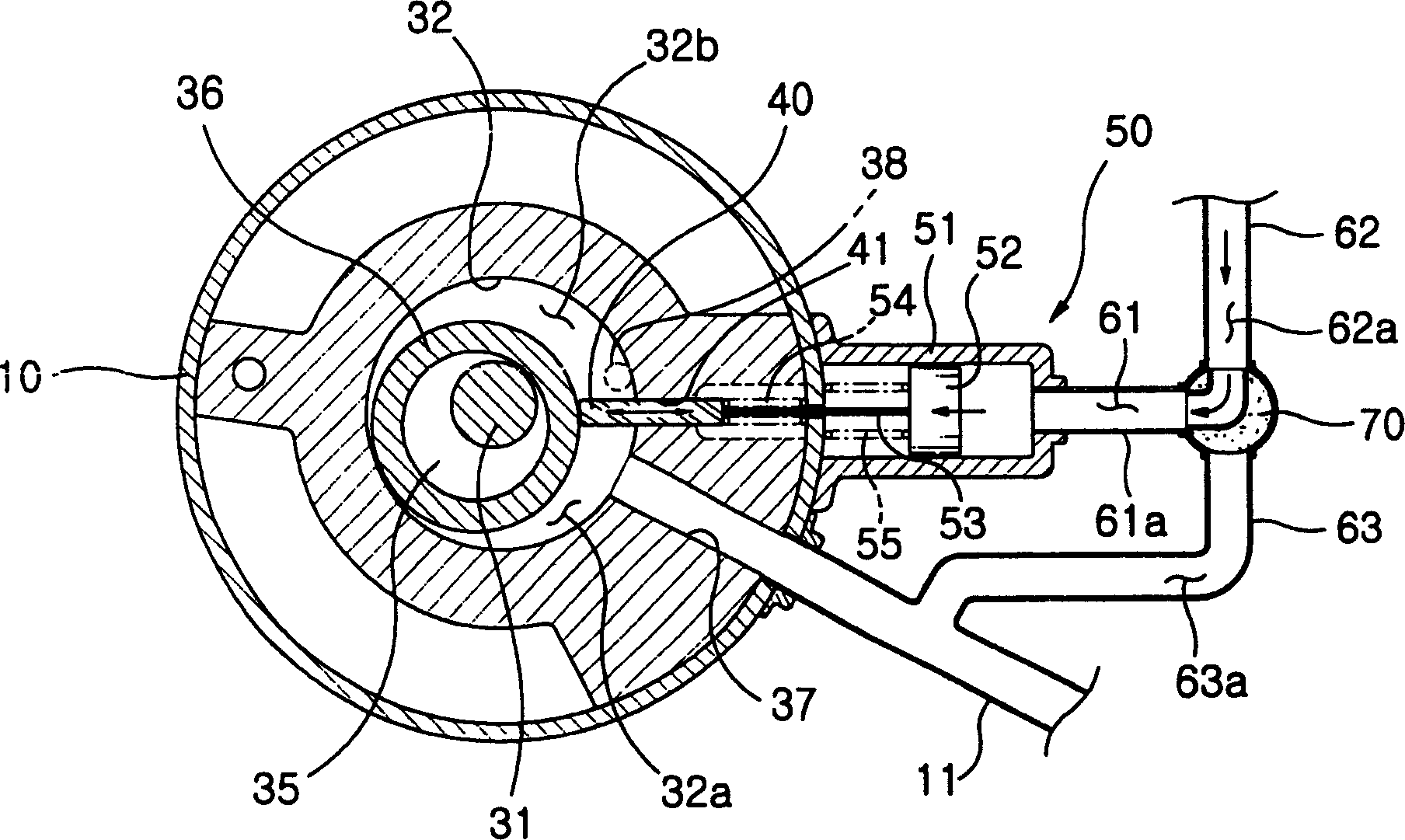

[0022] Figure 2 to 4 A variable capacity rotary compressor according to an embodiment of the present invention is shown. Such as figure 2 As shown, the compressor includes a sealed housing 10 in which a drive unit 20 and a compression unit 30 are installed. When the driving unit 20 is energized, the driving unit 20 generates rotational driving force. The compression unit 30 is connected to the drive unit 20 via a rotating shaft 21, for example.

[0023] The drive unit 20 includes a stator 22 and a rotor 23. The stator 22 is fixed to the inner surface of the sealed casing 10, and the rotor 23 is rotatably installed in the stator 22 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com