Refrigeration quantity transporting equipment for heat pipe type impulse pipe refrigerating machine

A pulse tube refrigerator and conveying device technology, which is applied in the direction of household refrigerators, refrigerators, gas cycle refrigerators, etc., can solve the problems of bulkiness, unsuitable cooling capacity transportation, complex structure, etc., and achieve high heat transfer capacity and weight Lightweight and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will further describe embodiment in conjunction with accompanying drawing:

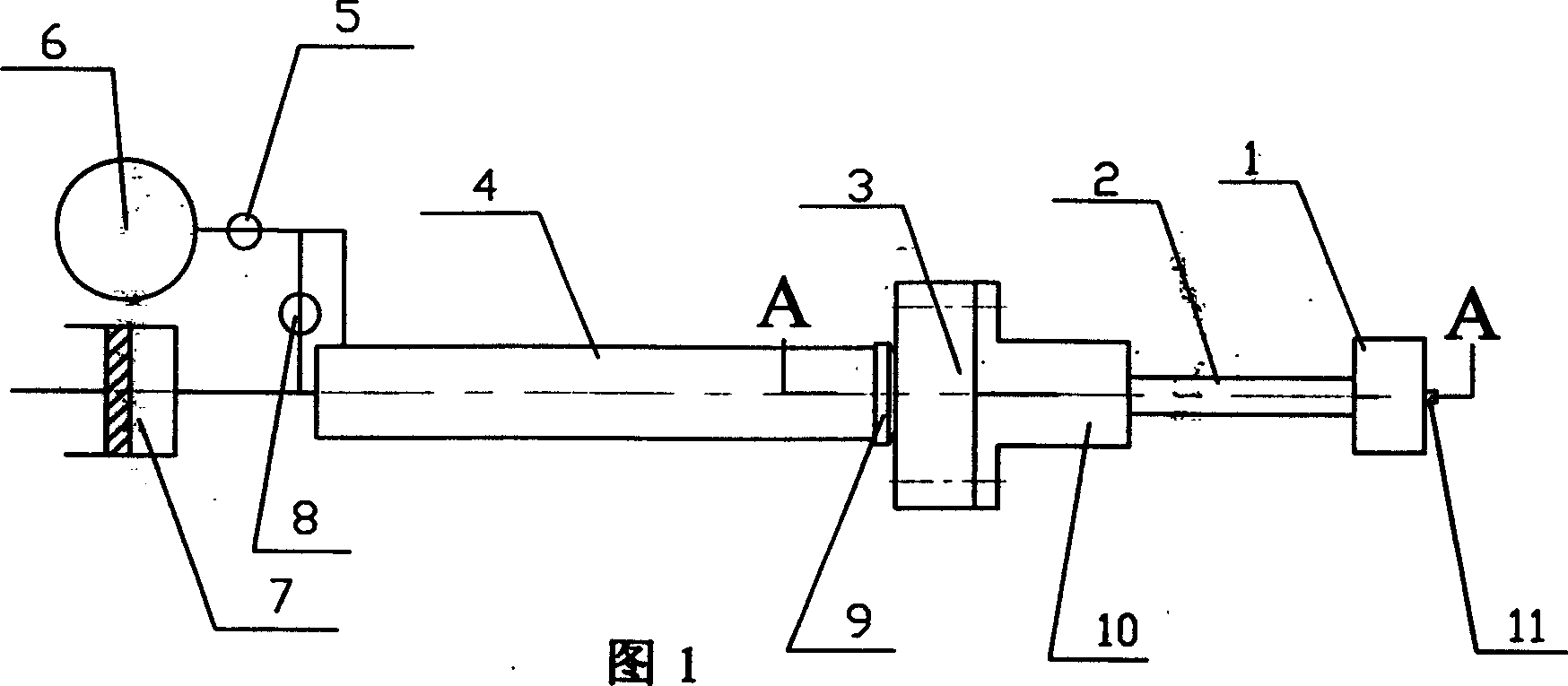

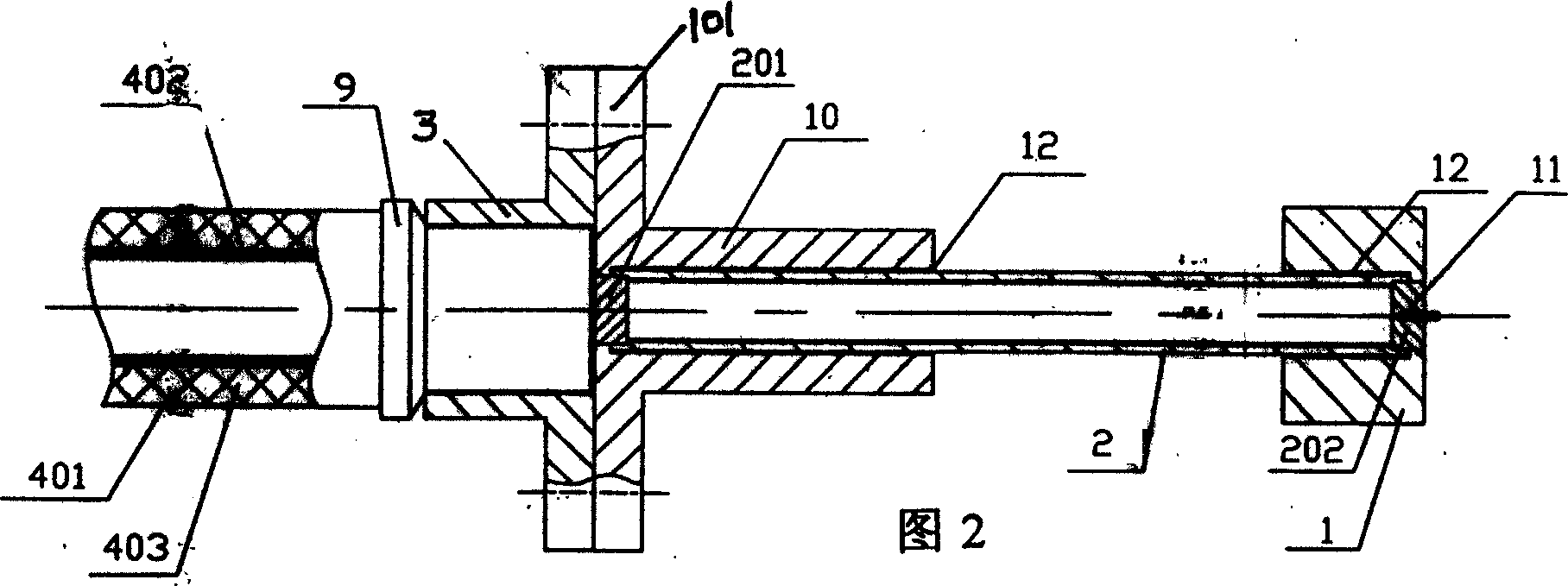

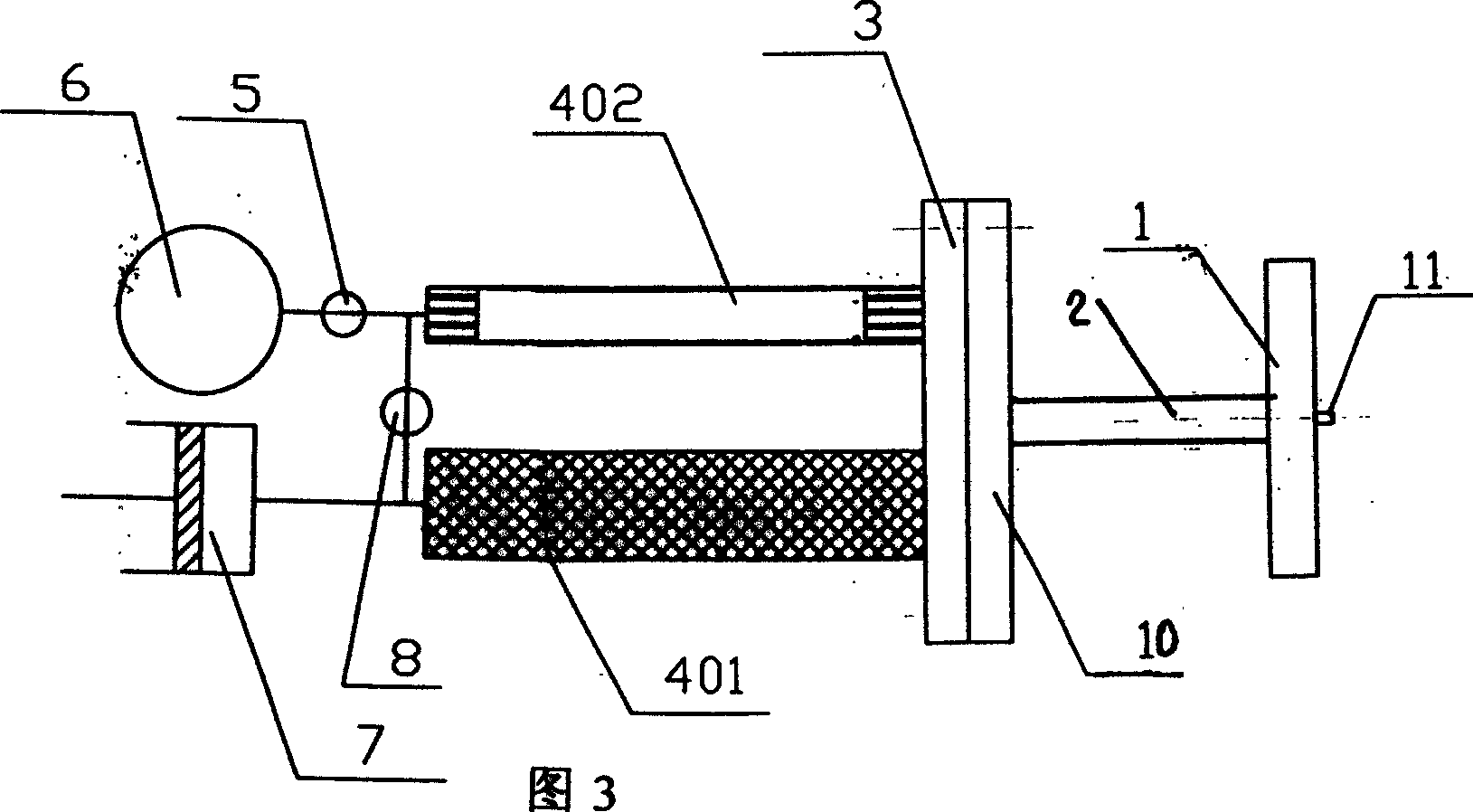

[0020] Fig. 1 and Fig. 2 are the structural representations of the present invention respectively, and the regenerator and the pulse tube (concentric) of the refrigerator are coaxially placed in Fig. 1, and the regenerator and the pulse tube (U type) of the refrigerator are coaxially placed in Fig. 3, Fig. 2 is a schematic cross-sectional view of A-A of Fig. 1; as can be seen from Fig. 1, Fig. 2 and Fig. 3, the cold delivery device of the heat pipe type pulse tube refrigerator provided by the present invention, the condensation section of the heat pipe 2 and the cold head 9 of the pulse tube refrigerator Coupling, the evaporating section of the heat pipe is coupled with the cooled device 1; the condensing section of the heat pipe is provided with a condensing section end cover 201, and the condensing section end cover 201 is directly contacted and coupled with the cold head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com