Prepn process and device of continuously variable light attenuating plate

A technology of attenuation sheet and glass substrate, which is applied in the field of preparation and realization of optical continuous variable attenuation sheet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

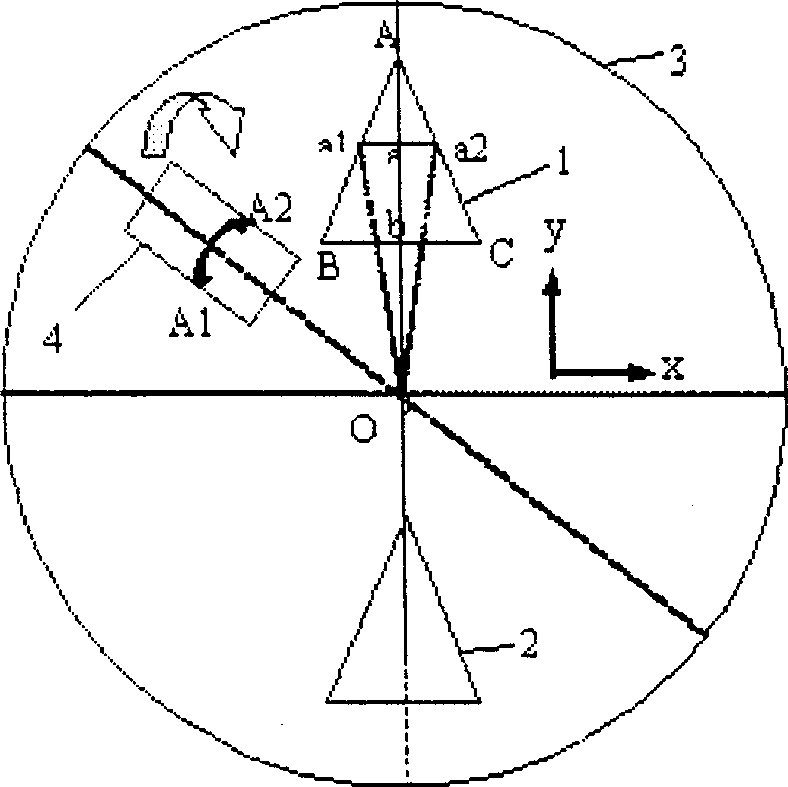

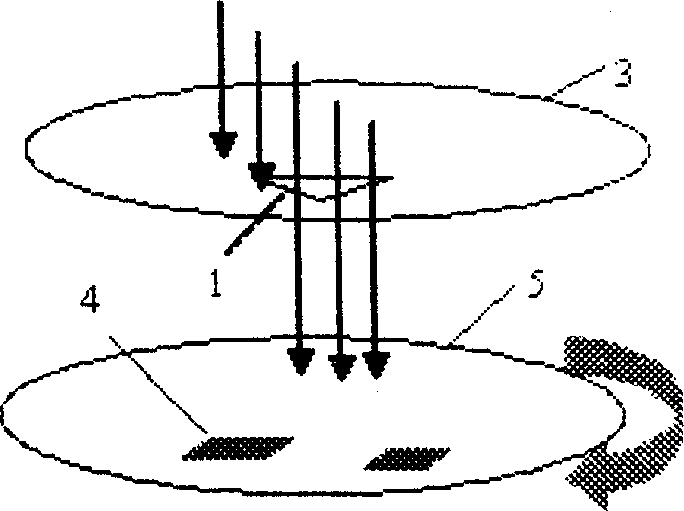

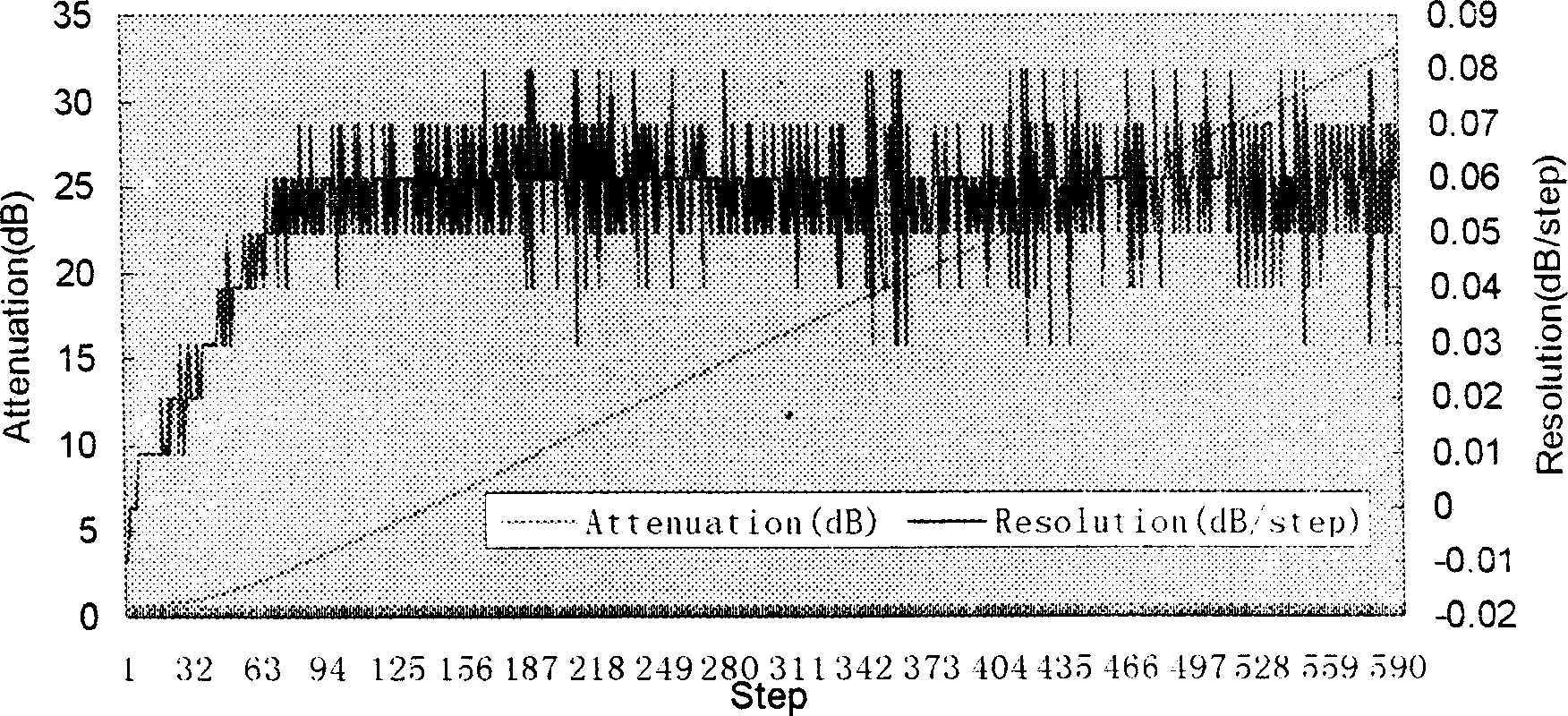

[0016] Combined with the structure of the vacuum chamber of the sputtering equipment, a circular deposition baffle 3 is designed, and a deposition hole with a certain pattern is dug on it. The top corner of the deposition hole 1 is facing away from the rotation axis O of the bottom plate 5, as figure 1 shown. The relative positions of sputtering deposition baffle plate 3, glass substrate 4 and base plate 5 in the vacuum chamber of the sputtering equipment are as follows: figure 2 As shown, the deposition baffle 3 and the bottom plate 5 are coaxial, the glass substrate 4 is placed on the bottom plate 5, the deposition hole 1 is located directly above the glass substrate 4, and the glass substrate 4 moves in a circle around the axis. The attenuator is deposited by DC sputtering, and the attenuation linearity is required to be L=ky, where L is the attenuation loss and y is the length of the attenuator. First measure the distribution of the target, and select a region with a rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com