Method for removing alkali-nitrogen compound from poor wax oil by complex extraction

A low-quality wax oil and extraction agent technology, applied in the petroleum industry, refined hydrocarbon oil, etc., can solve the problems of low alkali nitrogen removal rate and low raffinate yield, and achieve low solvent loss and raffinate yield. The effect of high efficiency and small ratio of agent to oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

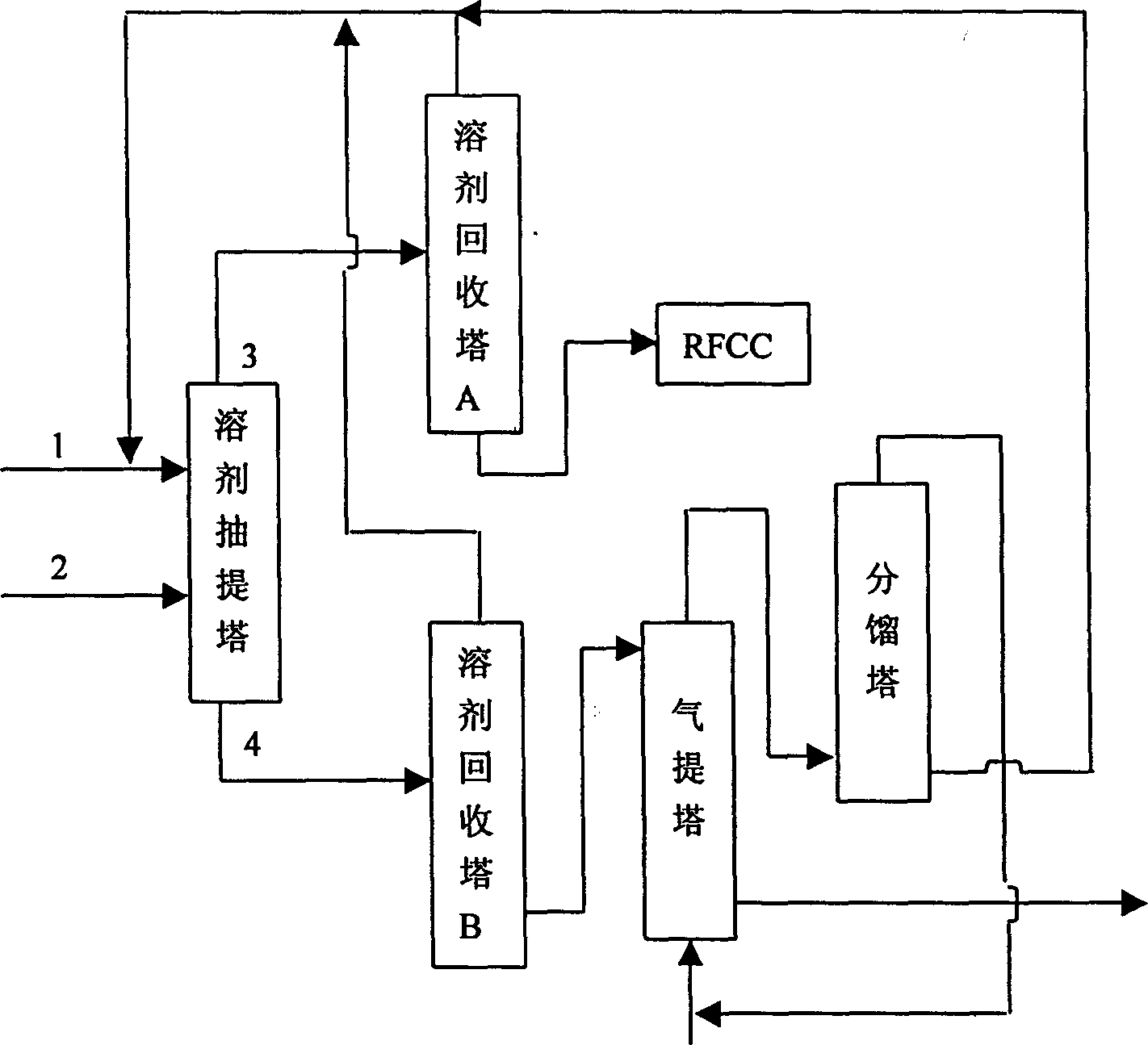

Method used

Image

Examples

Embodiment 1

[0018] The inferior oil properties of a certain factory are shown in Table 1. Using the solvent refining method of the present invention, 88 (weight)% acetic acid, 7% (weight) methyl alcohol and 5% (weight) Polyethylene Glycol are extractants, and the extractants are mixed with inferior oils. The volume ratio of the oil was 1:5, and the extraction and refining were carried out under the operating conditions of the extraction temperature of 50°C. The results are shown in Table 2.

Embodiment 2

[0020] The inferior oil properties of a certain factory are shown in Table 1. Using the solvent refining method of the present invention, 88 (weight)% of acetic acid, 7% (weight) methyl alcohol and 5% (weight) polyethylene glycol are used as extraction agents, and the extraction agent and the inferior oil The volume ratio of the oil was 1:1, and the extraction and refining were carried out under the operating conditions of the extraction temperature of 65°C. The results are shown in Table 2.

[0021] Table 1 Properties of low-quality oil in a plant

[0022] Raw oil CGO density (20°C), g cm -3 0.9127 distillation range, ℃

[0023] IBP / 10% 226 / 360

[0024] 30% / 50% 397 / 414

[0025] 70% / 90% 433 / 472

[0026] 95% / EBP 506 / 541S, wt% 1.82N, wt% 0.4398C, wt% 86.65H, wt% 11.83 base nitrogen, ug g -1 1126

[0027] Table 2

example 1

[0028] Example 1 Example 2 Furfural NMP raffinate base nitrogen content, ug / g 50 54 476 654 base nitrogen removal rate, % 95.58 95.2 57.9 42.2 raffinate oil yield, % 97.3 96.7 79.6 73.6 acetic acid recovery rate, % 99.2 98.9 - -

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com