Gas flow sensor

A gas flow and sensor technology, applied in the direction of liquid/fluid solid measurement, measurement flow/mass flow, instruments, etc., can solve the problems of complex structure, poor measurement accuracy, low sensitivity, etc., and achieve high measurement accuracy, fast response speed, The effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

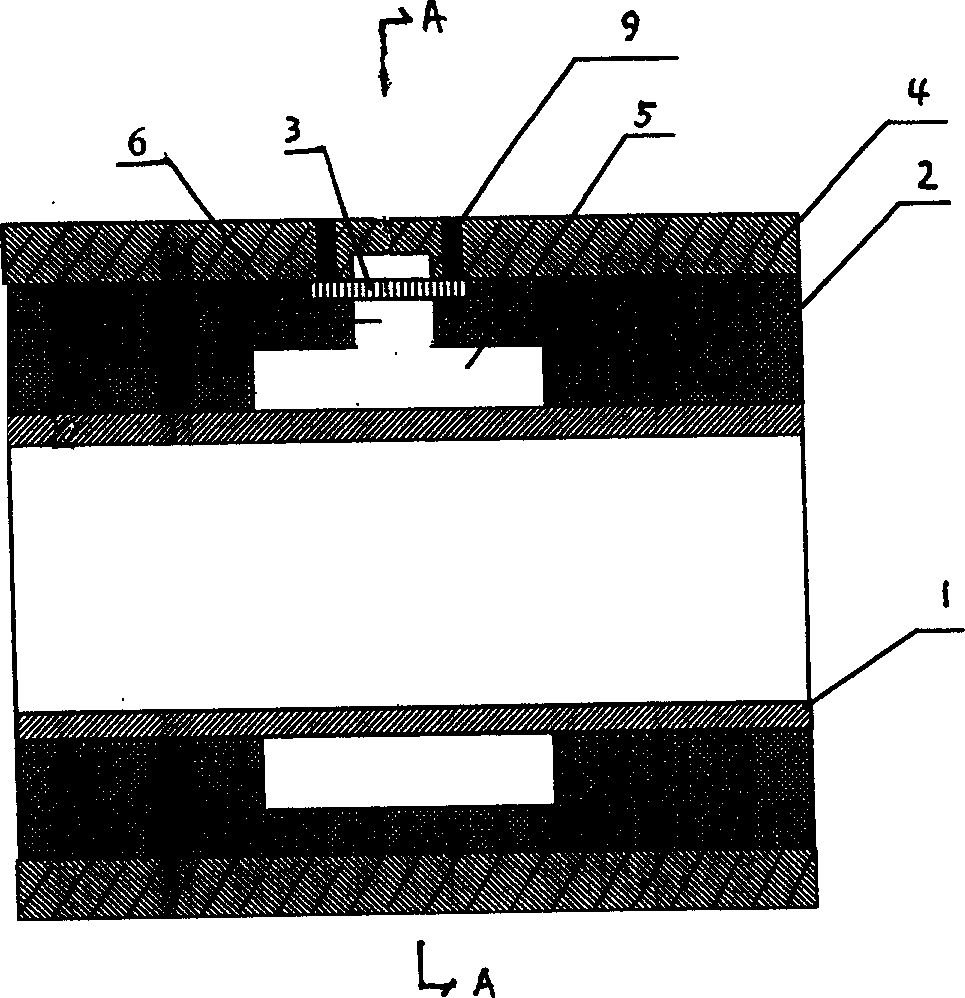

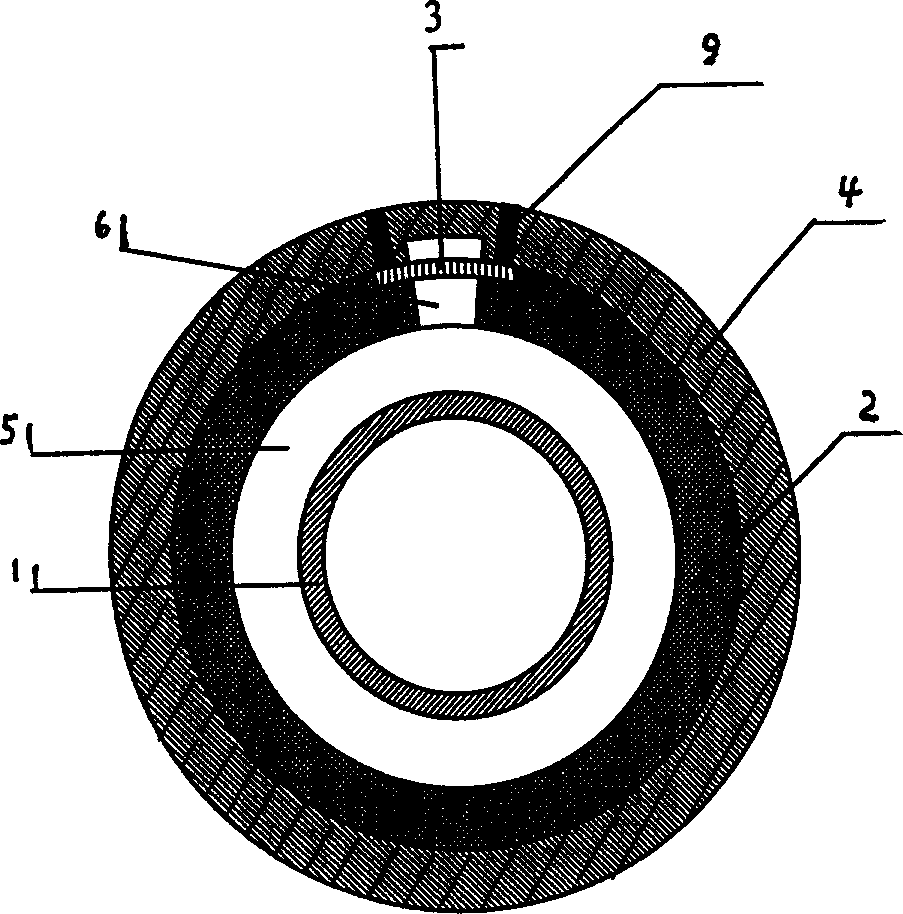

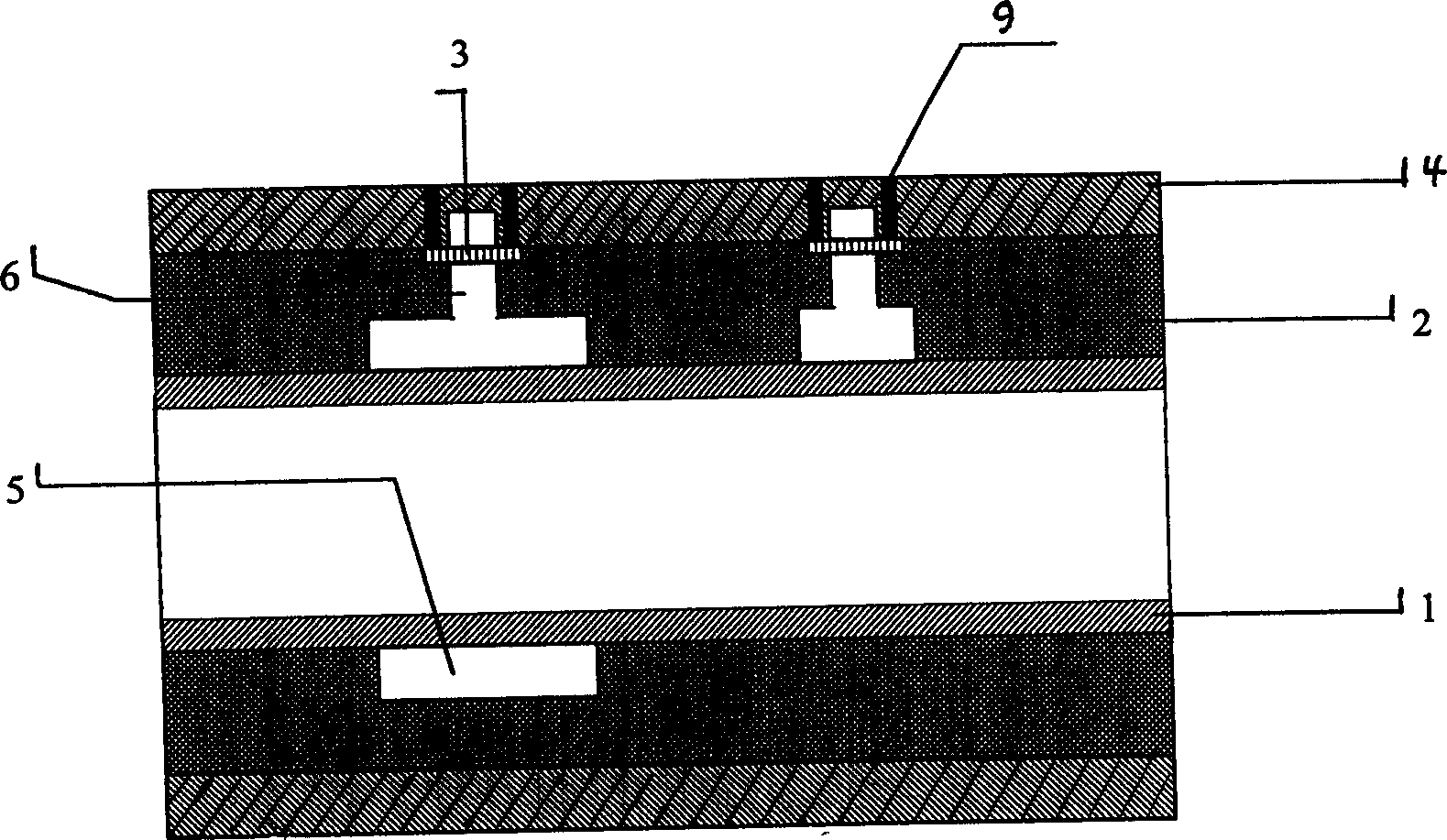

[0021] Referring to the accompanying drawings, the gas flow sensor of the present invention includes a tubular plastic shell 4, a tubular plastic inner shell 2 is inserted in the inner cavity of the outer shell 4, and a tubular plastic inner shell 2 is inserted in the inner cavity of the inner shell 2. A tubular metal inner membrane 1, the inner shell 2 is provided with 1-3 vibration cavities 5 and vibration transmission channels 6 respectively connected to each vibration cavity 5, wherein each vibration cavity 5 is along the inner circular surface of the inner shell 2 Setting, the inner casing 2 is equipped with induction diaphragms 3 that respectively block each vibration transmission channel 6, and each induction diaphragm 3 is connected with a metal post 9, and the vibration chamber 5 can be annular, semi-annular or arc-shaped , the sensing diaphragm 3 includes a varistor diaphragm, a piezoelectric diaphragm and a capacitive diaphragm, and other types of sensing diaphragms ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com