Instrument panel-air conditioning duct assembly for vehicle

A technology for instrument panels and aggregates, which is applied to instrument panels, vehicle parts, air handling equipment, etc., and can solve problems such as increased weight, large number of man-hours, and damage to the value of aggregates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

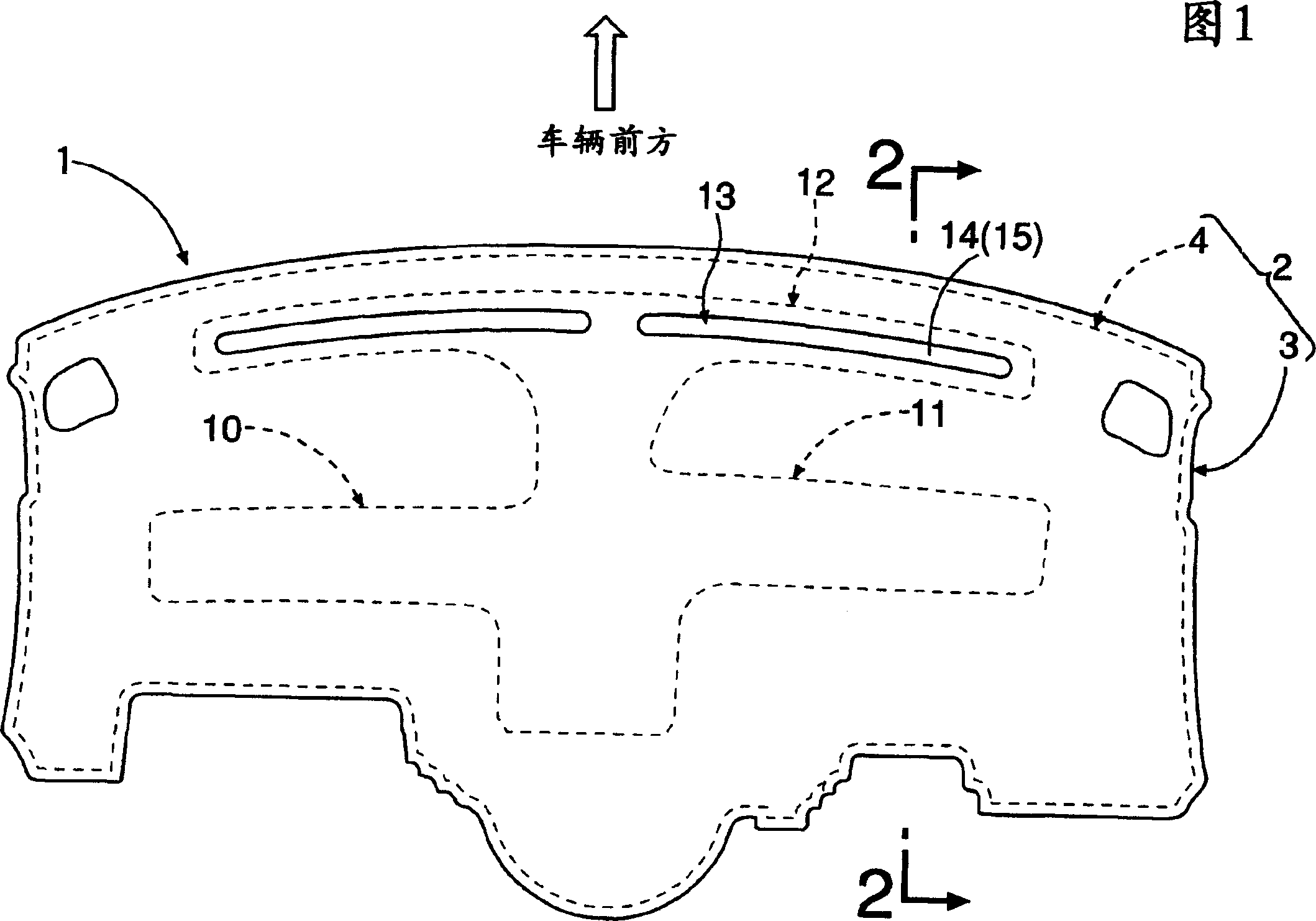

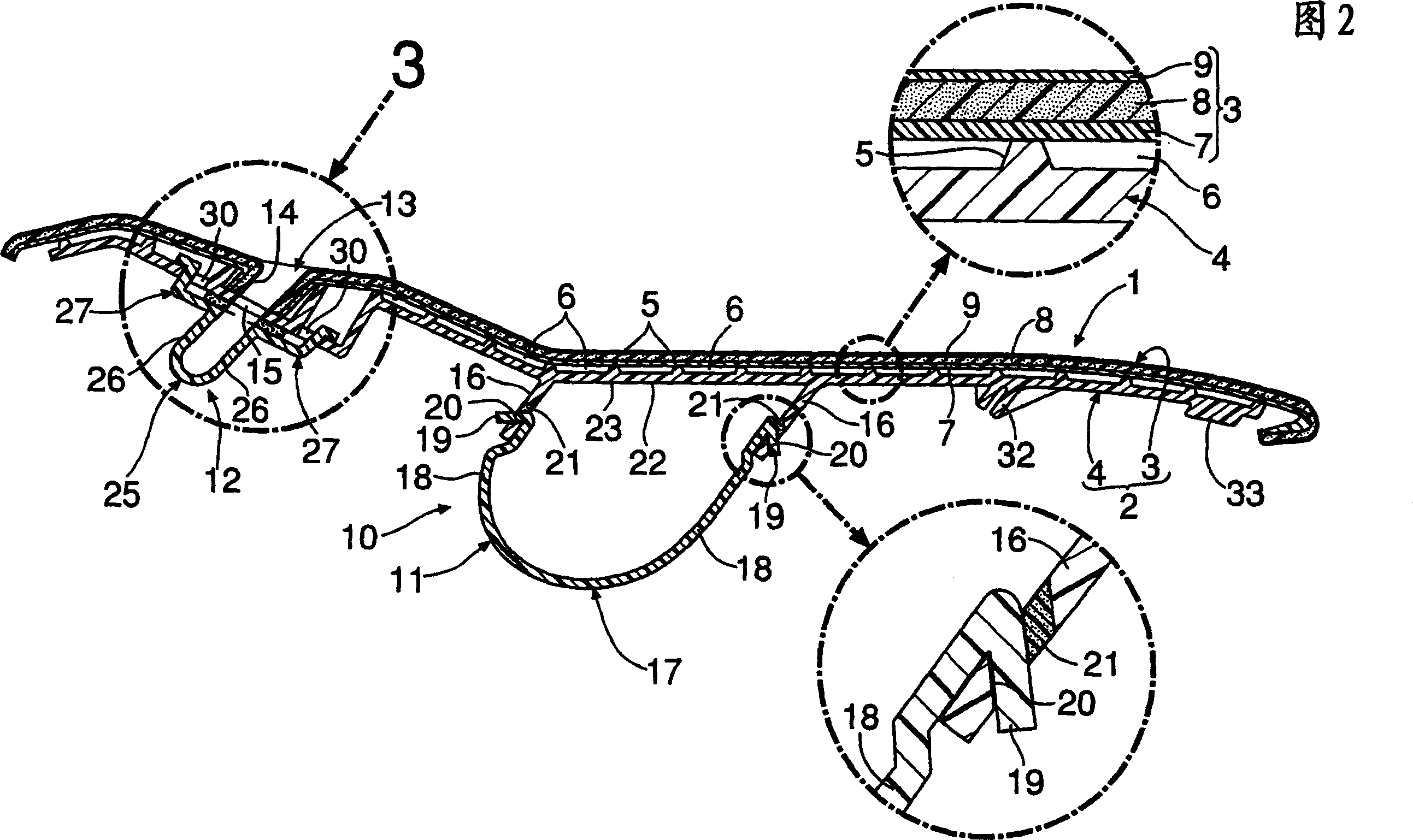

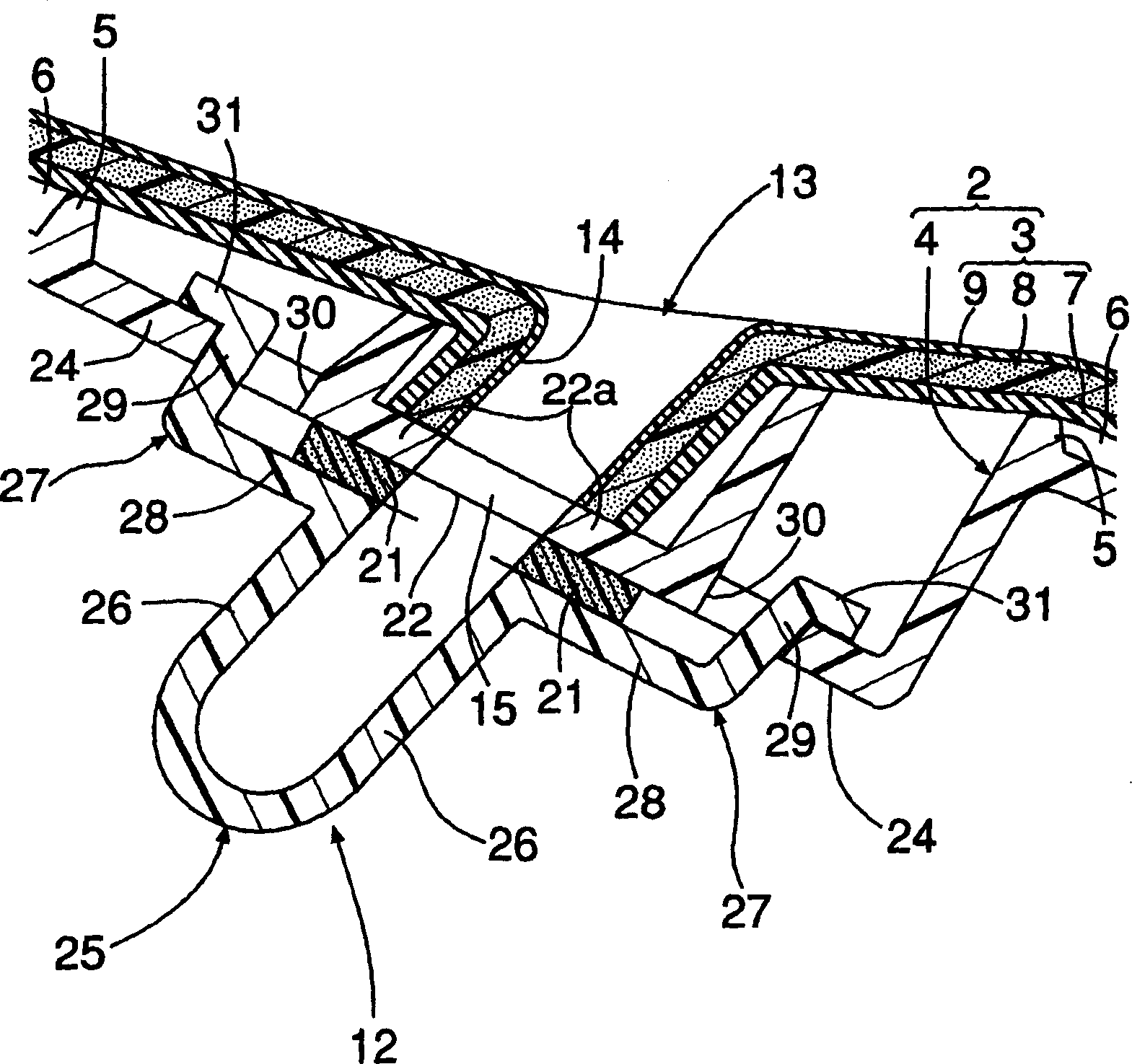

[0015] 1 and 2, the instrument panel 2 has a synthetic resin front side forming panel 3 and a synthetic resin rear side forming panel 4 covering substantially the entire inner surface of the panel 3. The back side forming plate 4 is connected to the front side forming plate 3 through a plurality of protrusions on its surface opposite to the front side forming plate 3, in this embodiment, a protrusion 5 extending in the left-right direction of the vehicle. In vibration welding, there is a gap 6 for heat insulation between the two formed plates 3 and 4 .

[0016] The front forming panel 3 is vacuum-formed from a single-layer sheet or a sheet having two or more layers, in this embodiment, a three-layer sheet, and a base layer made of PP (polypropylene) is used. 7. The buffer layer 8 integrated with the base layer 7 and made of PP foam, and the surface layer 9 integrated with the buffer layer 8 and made of TPO (thermoplastic olefin), the base layer 7 forms a plate vibration weldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com