Rolling die of ballscrew

A ball screw and mold technology, which is used in household appliances, metal rolling, manufacturing tools, etc., can solve the problems of shortening the durability of rolling molds, reducing the performance of roundness and shape transformation, and peeling off the machined surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Next, an embodiment of a rolling die for a ball screw according to the present invention will be described with reference to the accompanying drawings. Incidentally, in this embodiment, the same components as those in the conventional rolling die shown in FIG. 7 are given the same reference numerals, and thus their detailed descriptions are omitted here.

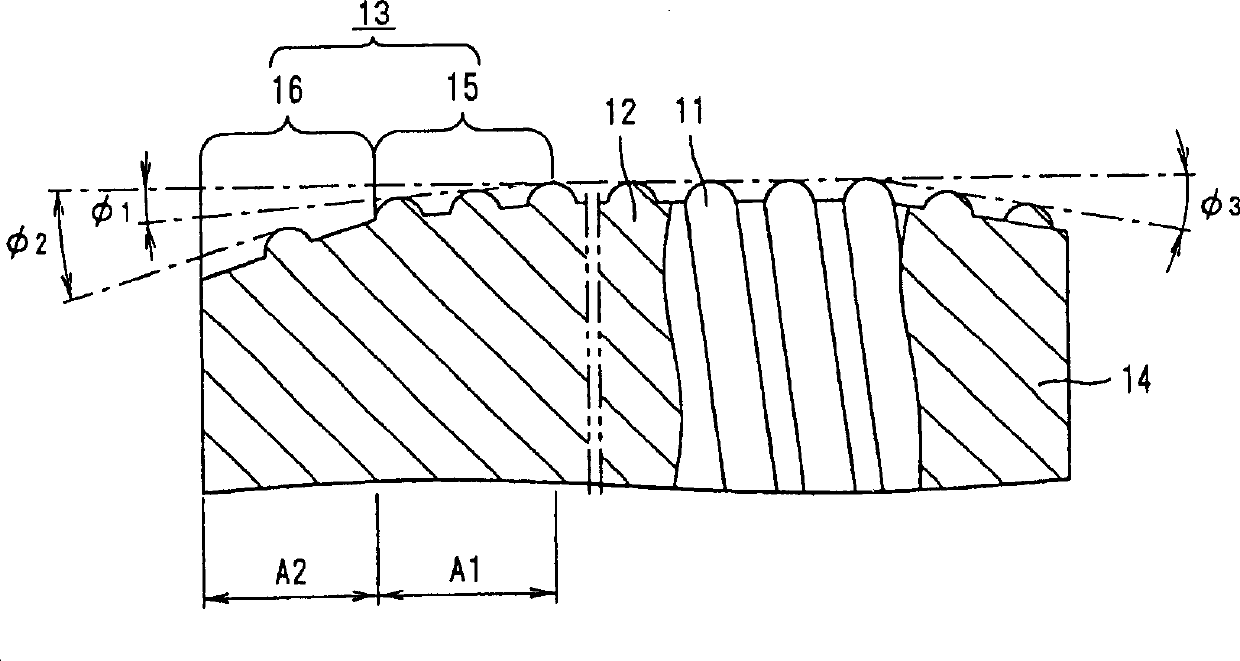

[0022] Fig. 1 is a sectional view of a part of a rolling die for a ball screw according to an embodiment of the present invention. As shown in FIG. 1 , the lead-in portion 13 on the ball screw rolling die according to the present embodiment is composed of two frustoconical portions 15 and 16 combined. For the two frustoconical portions 15 and 16, their respective blank contact angles φ1 and φ2 with respect to the screw blank differ from each other. Specifically, the blank contact angle φ1 of the frustoconical portion 15 adjacent to the cylindrical portion 12 has the following relationship with respect to the blank co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com