Method of forming metal wire of LCD device

A device and metal layer technology, applied in the field of liquid crystal display devices, can solve the problems of complicated reprocessing, failure of reprocessing of LCD devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Preferred embodiments of the invention will be described in detail with reference to the examples in the accompanying drawings.

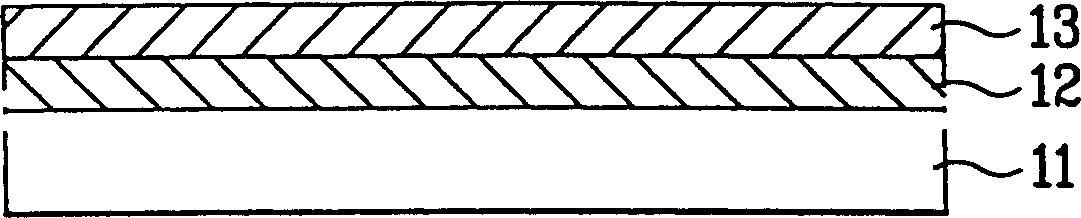

[0040] Figure 3A is an exemplary cross-sectional view illustrating a method of forming lines of an LCD device according to the present invention. Such as Figure 3A As shown in , an aluminum (pure aluminum) Al layer 22 or an aluminum alloy (AlNd) layer 22 and a molybdenum Mo layer 23 are deposited on a glass substrate 21 in sequence. In this example, the aluminum Al layer 22 may be formed in a thickness of 10 Å to 3000 Å, and the molybdenum Mo layer 23 may be formed in a thickness of 10 Å to 2000 Å.

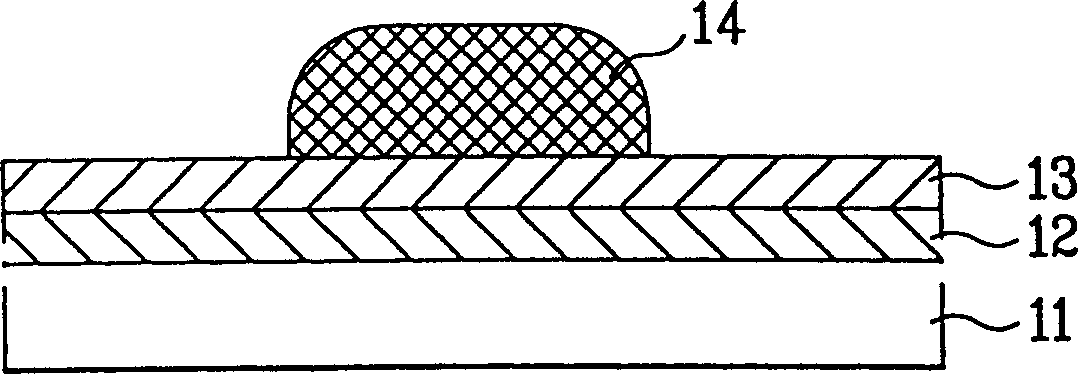

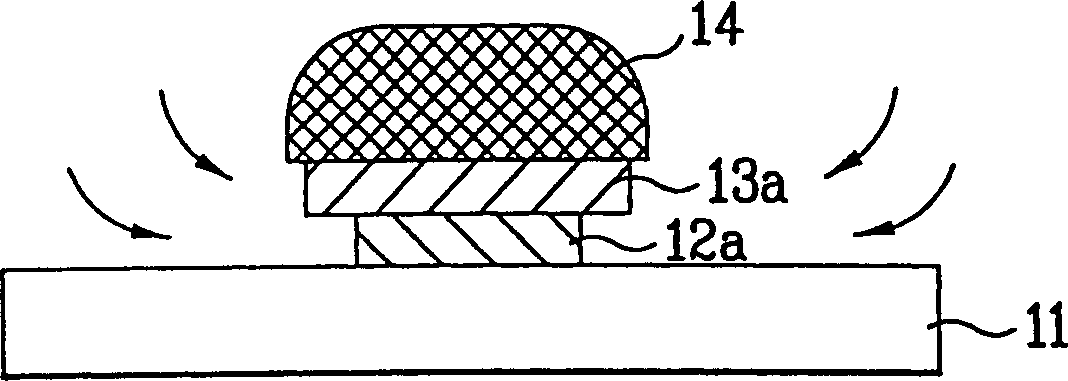

[0041] Figure 3B is an exemplary cross-sectional view illustrating a method of forming lines of an LCD device according to the present invention. Such as Figure 3B As shown in , a photoresist layer can be deposited on the entire surface of the molybdenum Mo layer 23, and a mask (not shown) is used to perform exposure and development proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com