Rotation rate-analog voltage transformation module

A conversion module and analog voltage technology, which is applied in the field of non-electricity-electricity signal conversion, can solve the problems of low profit, high use cost, and high price, and achieve the effects of continuous synchronization improvement, low use cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

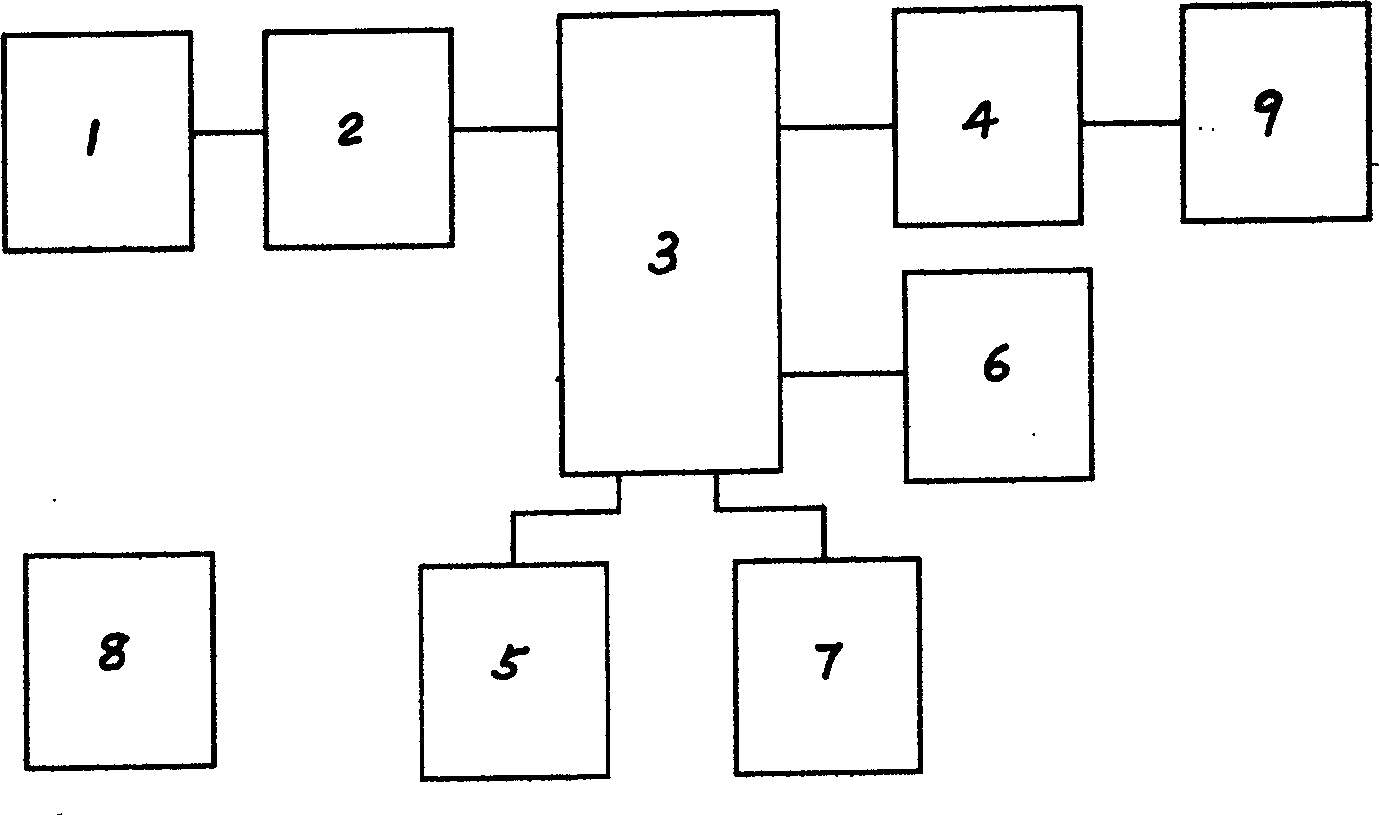

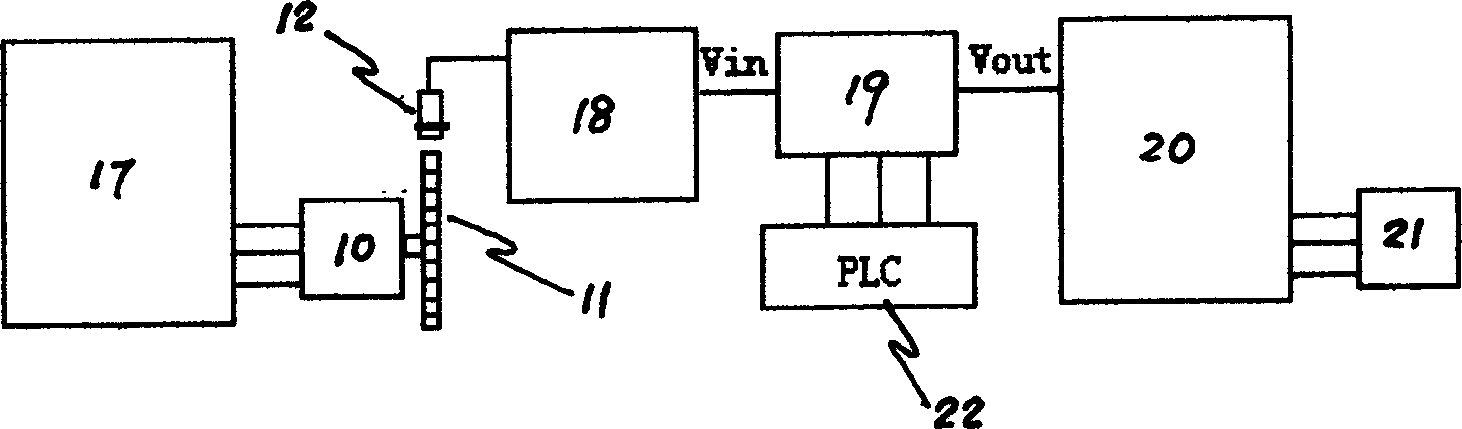

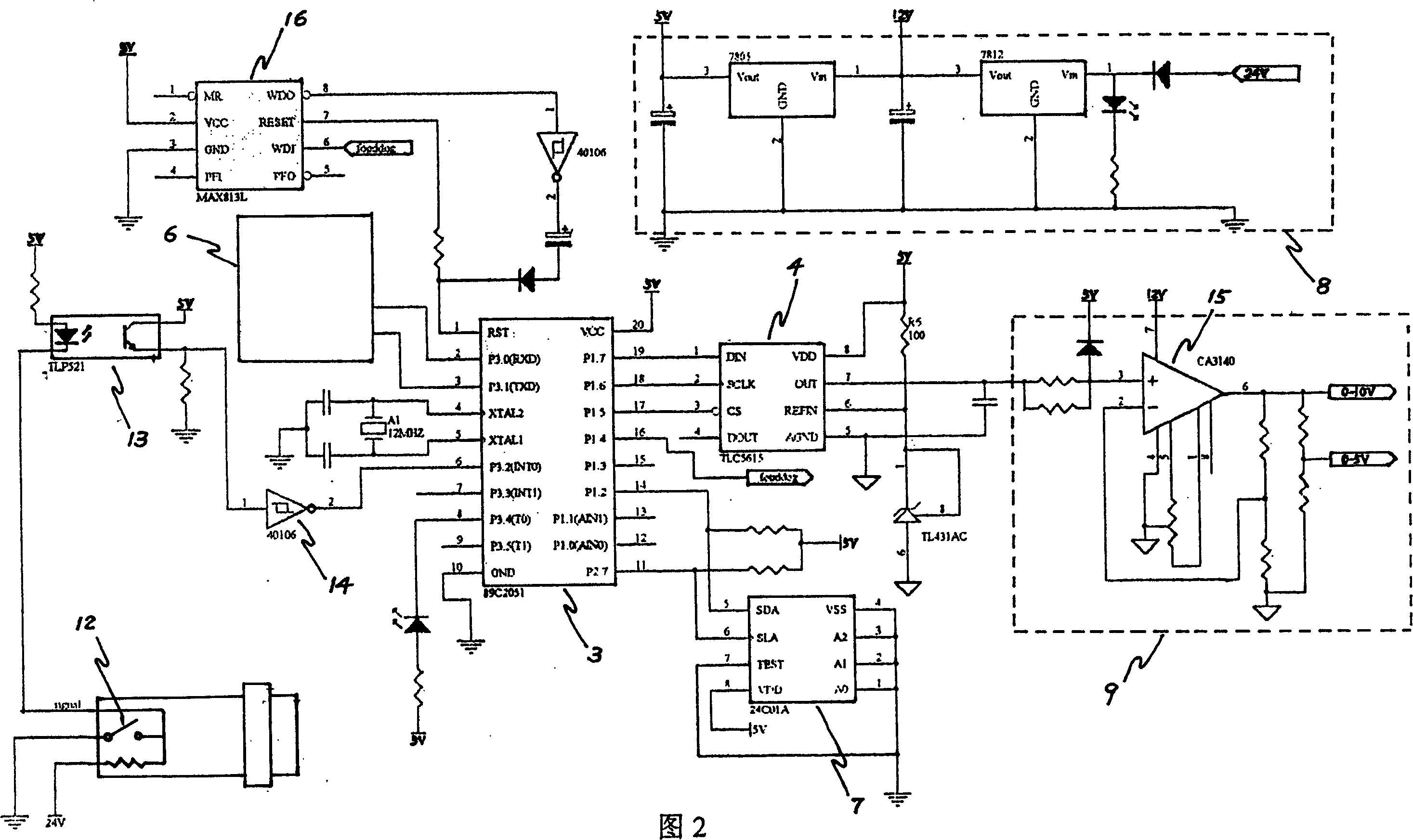

[0018] Example 1. A speed-analog voltage conversion module, such as Figure 1 to Figure 6 shown. It includes the casing and electronic circuits. The electronic circuit at least includes a rotational speed signal detection circuit 1, a signal processing circuit 2 connected to the rotational speed signal detection circuit 1, a signal operation single-chip microcomputer 3 connected to the signal processing circuit 2, a D / A conversion circuit 4 connected to the signal operation single-chip microcomputer 3, and An error detection circuit 5 connected to the single-chip signal computing 3, a display circuit 6 connected to the single-chip signal computing 3, a memory 7 connected to the single-chip signal computing 3, and a power supply circuit 8 for supplying power to the above-mentioned circuits. The D / A conversion circuit 4 outputs the analog voltage signal of this module. The D / A conversion circuit 4 can also be connected with the driving circuit 9 to output a higher driving cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com