Integrated hydroelectric power station

A technology for hydroelectric power stations and generator sets, which is applied in the field of hydroelectric power generation facilities, and can solve problems such as large waste of water sources, inability of generating sets to generate electricity, and inability to bear base loads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

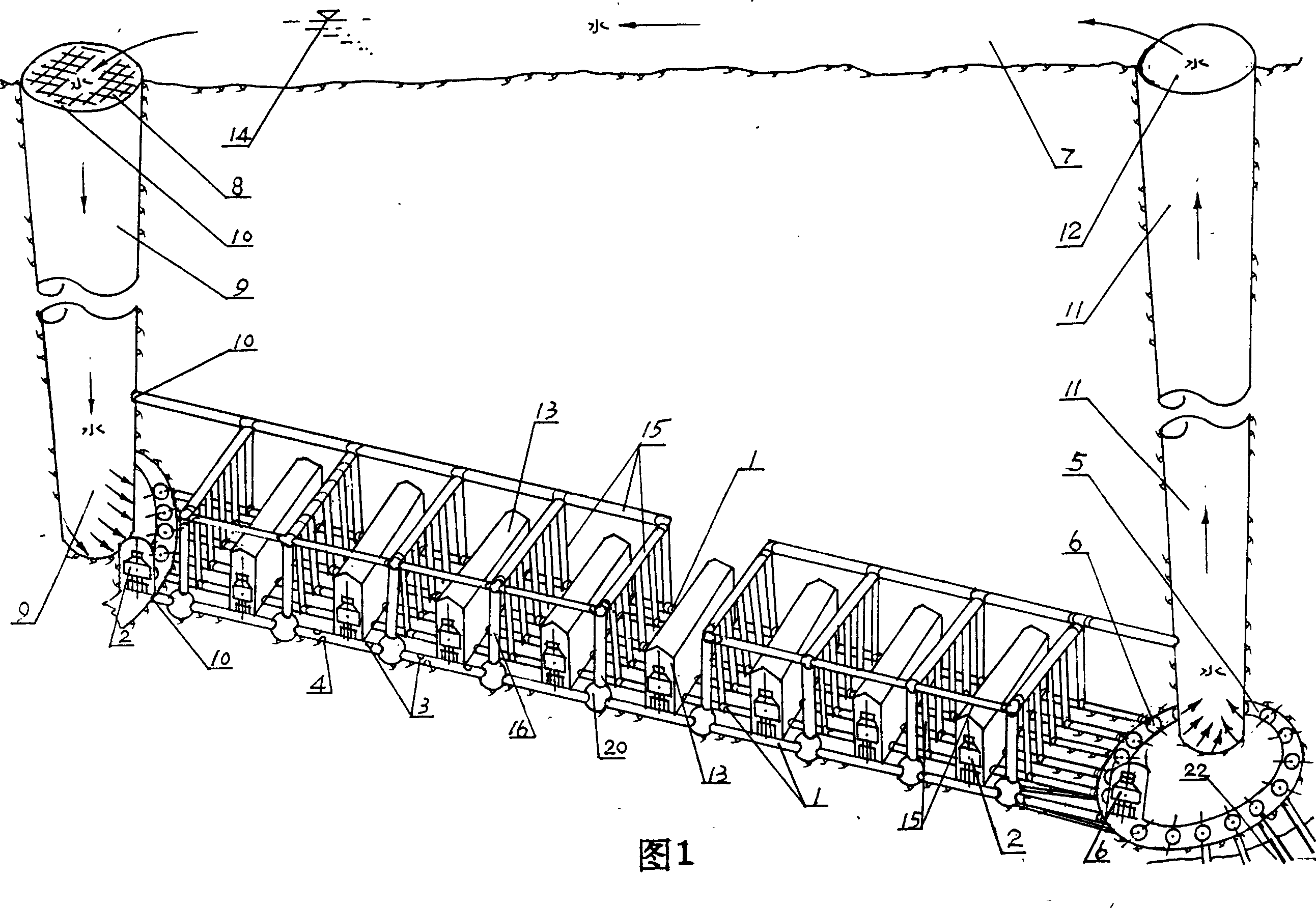

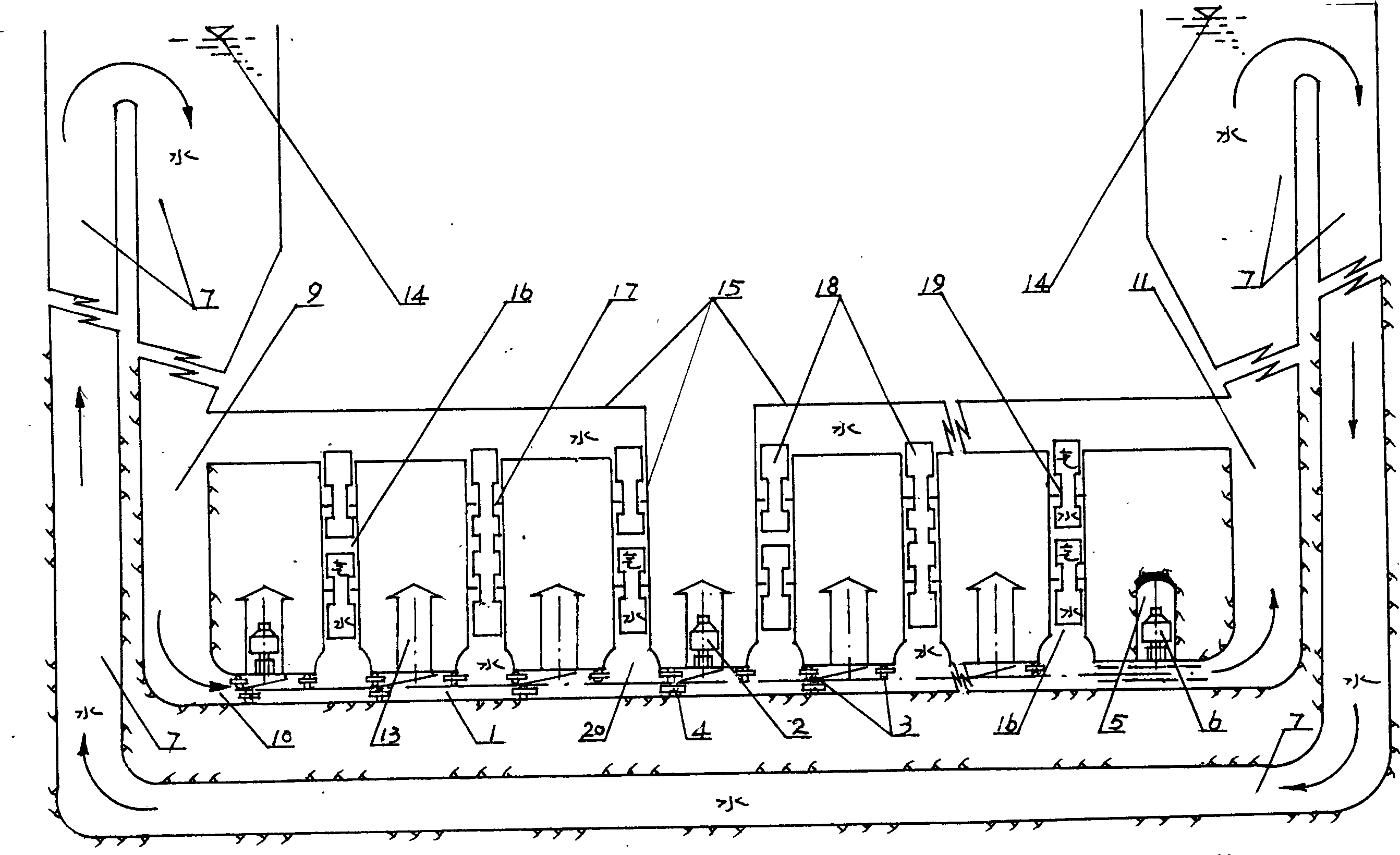

[0027] See Figure 1, which is the Dinovic (ground type) integrated hydroelectric power station, composed of Okkiyojin, Parsenzaro, Numahara, Daping, Yuyuan, Oyoshino, Motogawa, Hermes and Dinovic nine A collection of sub-stations (13) and pumping stations (5), with a storage capacity of 3×106m built on a ridge 550 meters high 3 The Tianchi Lake (7), with a cycle of 2 hours / time, the first station Okukiyojin (13) is built in the arc-shaped underground powerhouse (13) around the base of the liquid column 490m (14), from Pasenza with a liquid column head of 495m Starting from Luo substation (13), they are all ground substations (13), with an interval of 100m between the upper and lower substations, and a slope of 5%-6%. Substations (13), six pressure pipelines (1), flow rate is 65.0m 3 / s, 54 units (2) can be put into operation at the same time at peak load. The pump station (5) has n×12 main pumps (6) with a flow rate of 32.5m 3 / s, and another 6×3 pumps (6), the flow rate is...

Embodiment 2

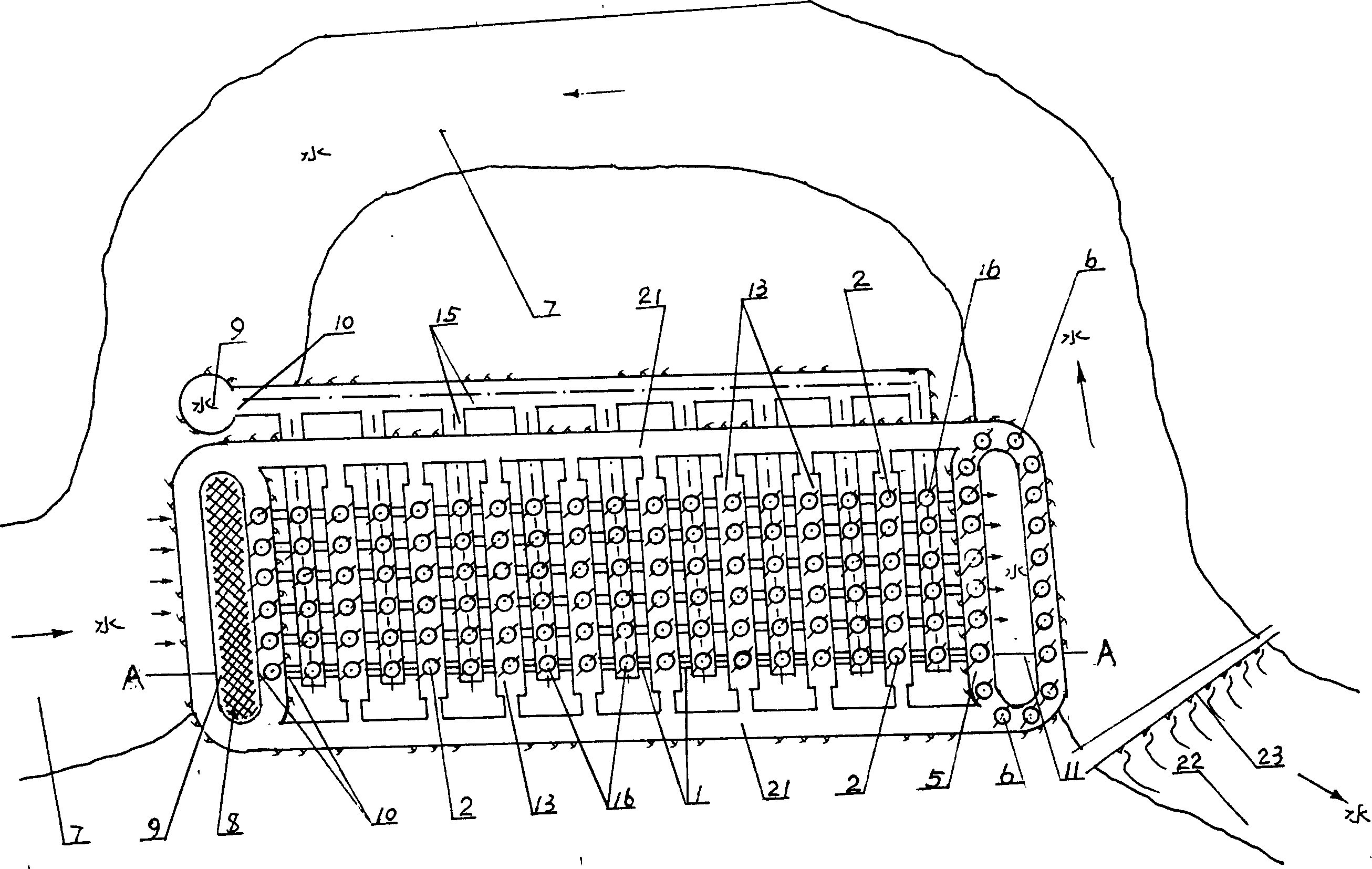

[0033] See image 3 , Figure 4 , is Butte Creek (underground) integrated hydroelectric power station, which consists of nine branches including Nanyuan, Lakong Mountain, Castaque, Gilboa, Mosor, Roudongde, Cabin Creek, Kraken and Butte Creek. Station (13) and water pumping station (5) are assembled. At the bend of a river (22), a 1.5-kilometer-long underground tunnel is built with a factory. The first station, Nanyuan (13), has a liquid column head of 318m (14), and the last station Butte Creek (13) has a liquid column equivalent head of 368.8m (14). The interval between the upper and lower substations is 150m, and the station is built according to the slope of 1 / 30 and 1 / 21. There are nine substations (13) and six output pipelines (1) , the flow rate of the main and auxiliary pumps is 95.3m 3 / 9, 16.0m 3 / 9, all in the elliptical ring-shaped underground pump house (5) under the pressure of 379.5m liquid column head (14) to pump and store circulating water in turns, each s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com