High-efficiency high-brightness multiple active district tunnel reclaimed white light light emitting diodes

A light-emitting diode, high-brightness technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of low absorption rate of phosphor powder, short life of phosphor powder, low color rendering index, etc., and achieve high luminous efficiency and improved quantum efficiency , Chroma realistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

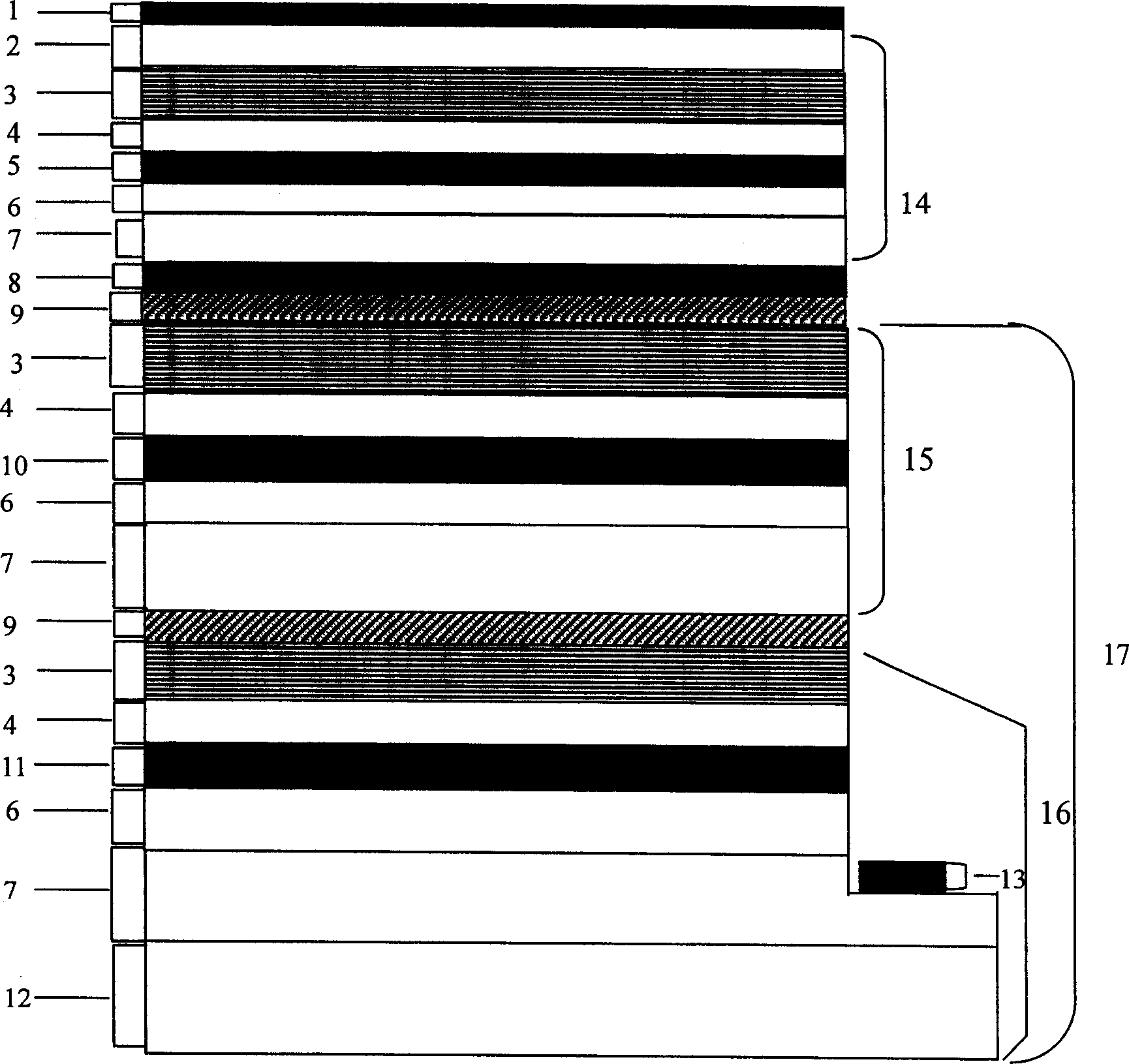

[0036] Such as Figure 7 Shown, its preparation process and method are as follows:

[0037] 1. Use common MOVCD method in N + - On the GaAs substrate, epitaxially grow N++GaAs / P++GaAs tunnel junction 9, N-GaInP transition layer 7, N-AlInP lower confinement layer 6, AlGaInP / GaInP heterojunction light-emitting region 5, and P-AlInP top Confinement layer 4, p+GaAs contact layer 2. Then, the red light-emitting unit 14 is obtained by evaporating or sputtering the p-type metal electrode Ti / Au (1) on the front side, and then removing the substrate GaAs through a grinding and thinning process;

[0038]2. On the sapphire or SiC substrate, grow n-GaN transition layer 7, n-InGaN lower confinement layer 6, InGaN / GaN multi-quantum well blue light emitting region 11, p-AlGaN upper confinement layer 4, AlInN / GaN DBR Blue light reflection layer 3, n++InGaN / P++GaN tunnel junction 9, n-GaN transition layer 7, n-InGaN lower confinement layer 6, InGaN / GaN multi-quantum well green light emittin...

Embodiment 2

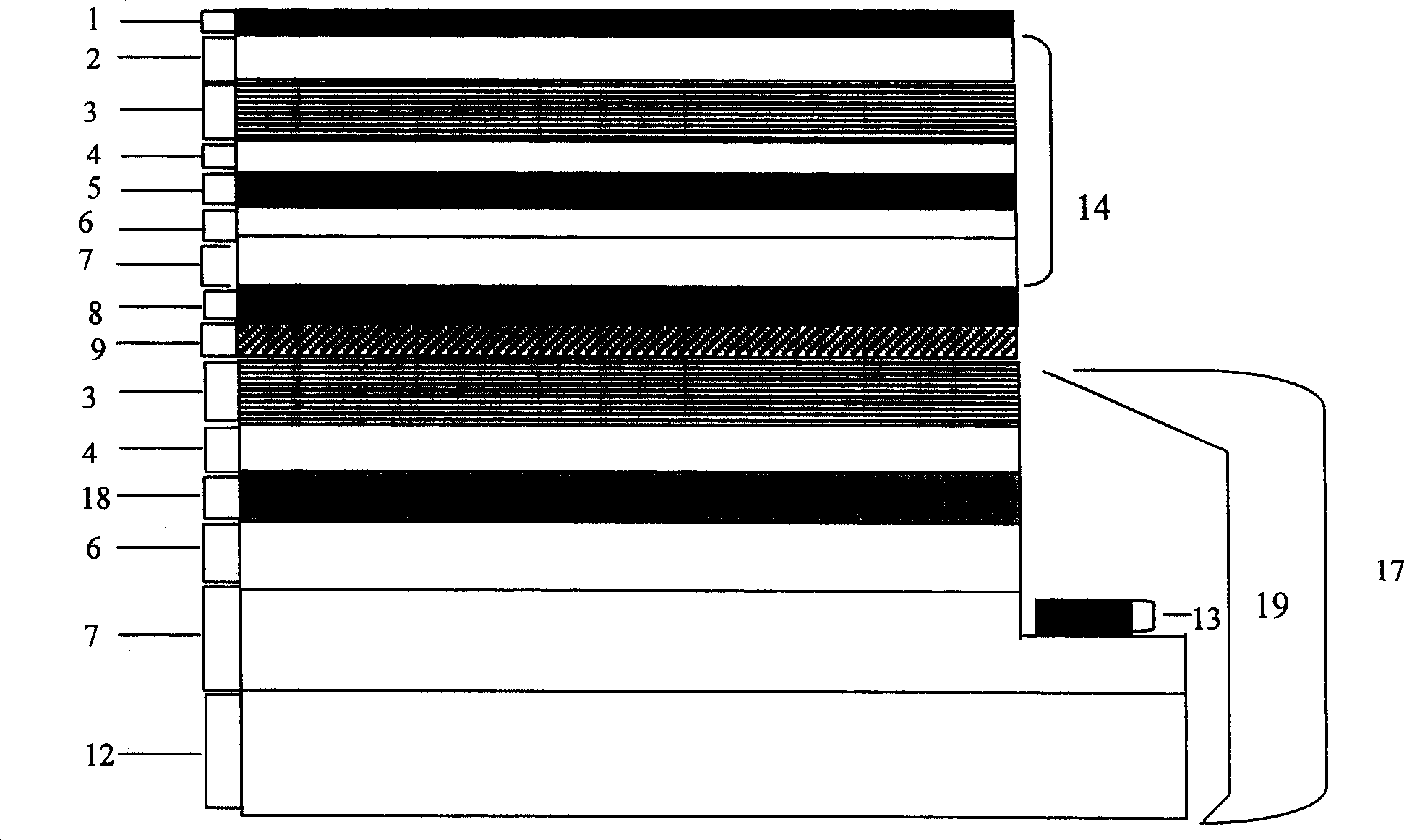

[0041] Such as Figure 8 Shown, its preparation process and method are as follows:

[0042] 1. Use common MOVCD method in N + - On the GaAs substrate, epitaxially grow N++GaAs / P++GaAs tunnel junction 9, N-GaInP transition layer 7, N-AlInP lower confinement layer 8, AlGaInP / GaInP heterojunction light-emitting region 5, and P-AlInP top Confinement layer 4, p+GaAs contact layer 2. Then, the red light-emitting unit 14 is obtained by evaporating or sputtering the p-type metal electrode Ti / Au (1) on the front side, and then removing the substrate GaAs through a grinding and thinning process;

[0043] 2. On a sapphire or SiC substrate, grow n-GaN buffer layer 7, n-InGaN lower confinement layer 6, InGaN / GaN multi-quantum well blue-green light-emitting region 18, p-AlGaN upper confinement layer 4, AlInN / GaN DBR blue light reflection layer 3, P++GaN contact layer 2, evaporate n-type electrode 13 after photolithography and etching to form a combination of blue and green light emittin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com