Shock-proof material composition

A composition and polymer technology, applied in the direction of solid shock absorbers, etc., can solve problems such as hindering industrial applications, narrowing the temperature range, and easily destroying the interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

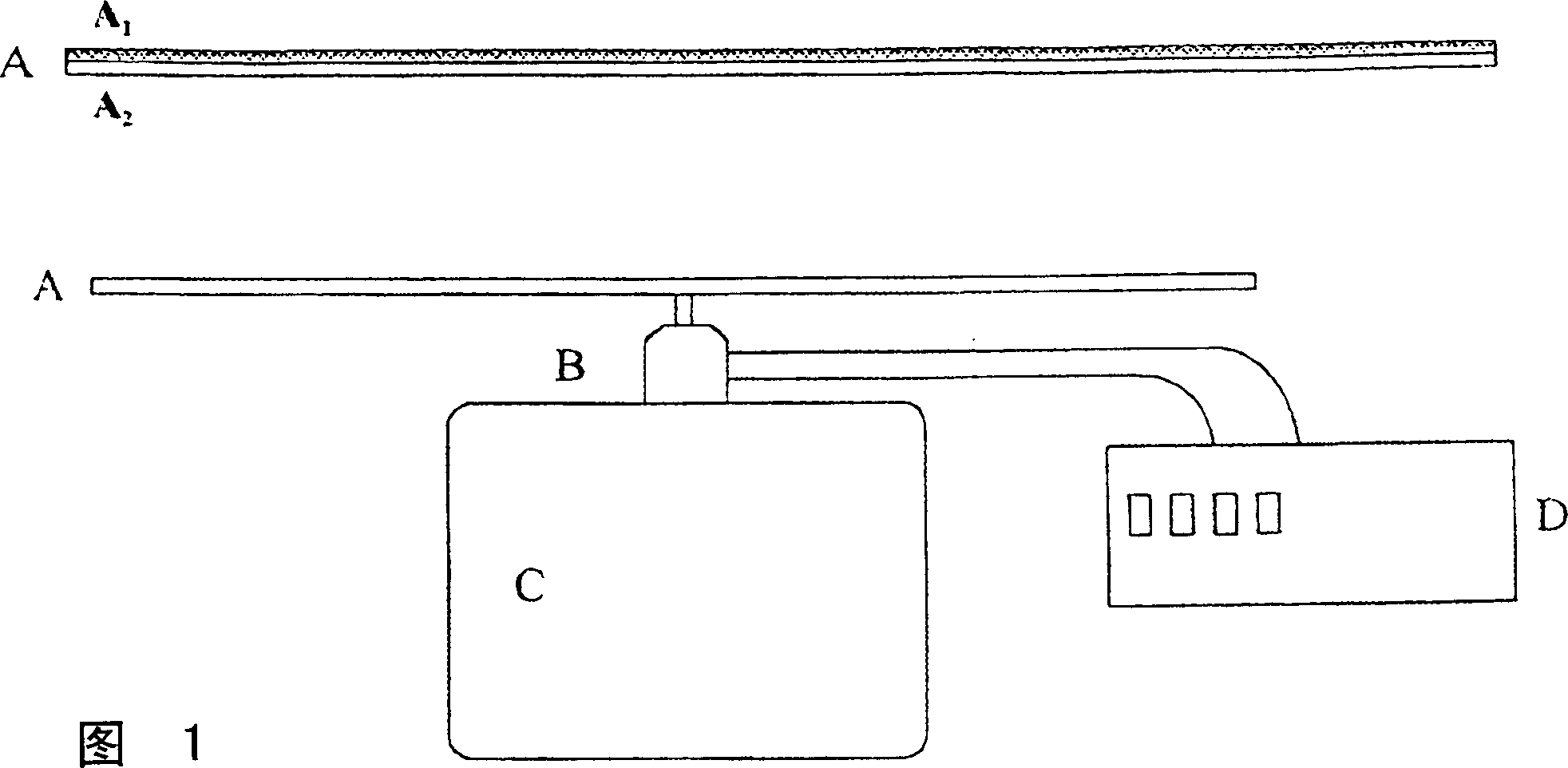

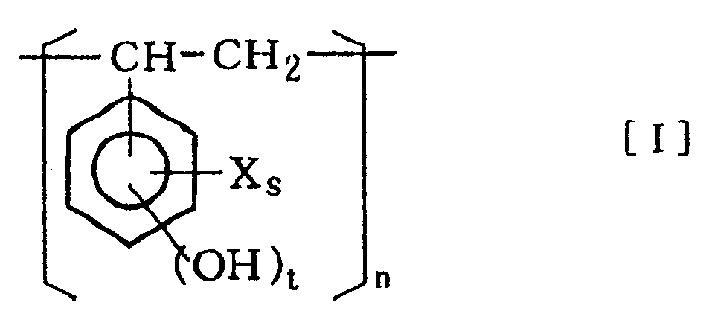

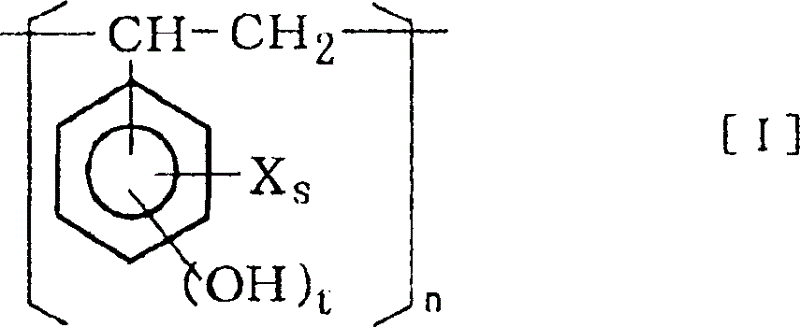

Method used

Image

Examples

Embodiment 1-7

[0080] Vibration damping material compositions were prepared in each of Examples 1-7 in which 100 parts of acrylic rubber as the organic polymer binder material were combined with different poly-4-vinylphenol resins as damping agents given in Table 1 (Poly-p-vinylphenol resin) ("Marukalyncur-M" series of Maruzen Petrochemical) mixed, and the amount of vibration damping agent is also given in Table 1. Each mixture is at 180°C and 200kgf / cm 2 Under hot pressing, a sheet-like vibration damping material composition with a thickness of 1 mm was formed. The evaluation results are given in Table 1.

Embodiment 8 and 9

[0082] Vibration damping material compositions were prepared in each of Examples 8 and 9 in which a 50 / 50 mixture of polylactic acid resin and polybutene succinate with different poly-4-ethylene as damping agents given in Table 1 phenol resin ("Marukalyncur-M" series of Maruzen Petrochemical) was mixed, and the amount of vibration damping agent is also given in Table 1. Each mixture is at 180°C and 200kgf / cm 2 Under hot pressing, a sheet-like vibration damping material composition with a thickness of 1 mm was formed.

Embodiment 11-14

[0097] In each of Examples 11-14, a vibration damping material composition was prepared in which a mixture of acrylic rubber and polypropylene in the ratios given in Table 3 was mixed with poly-4-vinyl as a vibration damping agent given in Table 3. Phenol resin was mixed, and the amount of damping agent was also given in Table 3. Each mixture is at 140-180°C and 100-200kgf / cm 2 Under hot pressing for 20 minutes, a sheet-like vibration damping material composition was formed.

[0098] The vibration damping performance was determined by measuring the temperature region in which each sheet-like composition could maintain its dissipation factor (?) at 0.08 or more by the aforementioned method. The evaluation results are given in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com