Digital controlled five shaft linked plane intrinsic ring surface scroll tooth cutting machine tool

A plane-enveloping, toroidal worm technology, applied in worms, driving devices, mechanical equipment, etc., can solve problems such as low production efficiency, high workpiece cost, and expensive machine tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

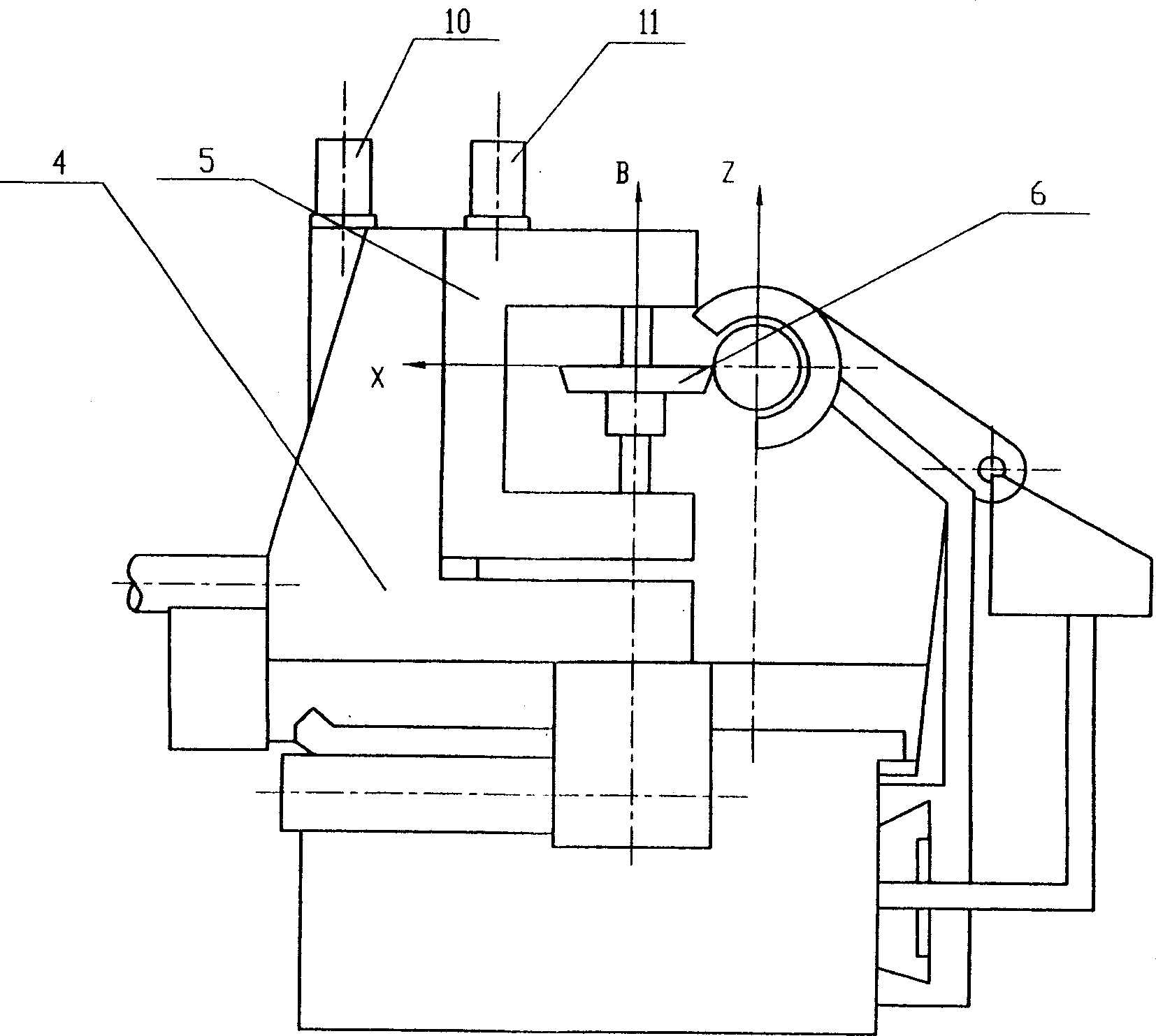

[0027] Embodiment 1: As shown in Figures 4, 5 and 6, a longitudinal slide 3 is installed on the bed 1, and the headstock 2 and tailstock 7 are fixed on the slide 3. The workpiece is installed between the main shaft and the tailstock, the main shaft A controls the rotation of the workpiece by the servo motor 9, the longitudinal slide table moves the workpiece along the Y axis by the servo motor 13, the slide plate 4 is installed on the bed 1, and is driven by the servo motor 12. The sliding plate 4 is fed horizontally along the X axis, and the rotary tool 6 is installed on the tool holder 5 of the vertical guide rail. The rotation of the tool around the B axis is realized by the servo motor 11. Lifting along the Z-axis, the speed of the A-axis can be automatically selected according to the size and speed of the workpiece to ensure a constant cutting speed.

Embodiment 2

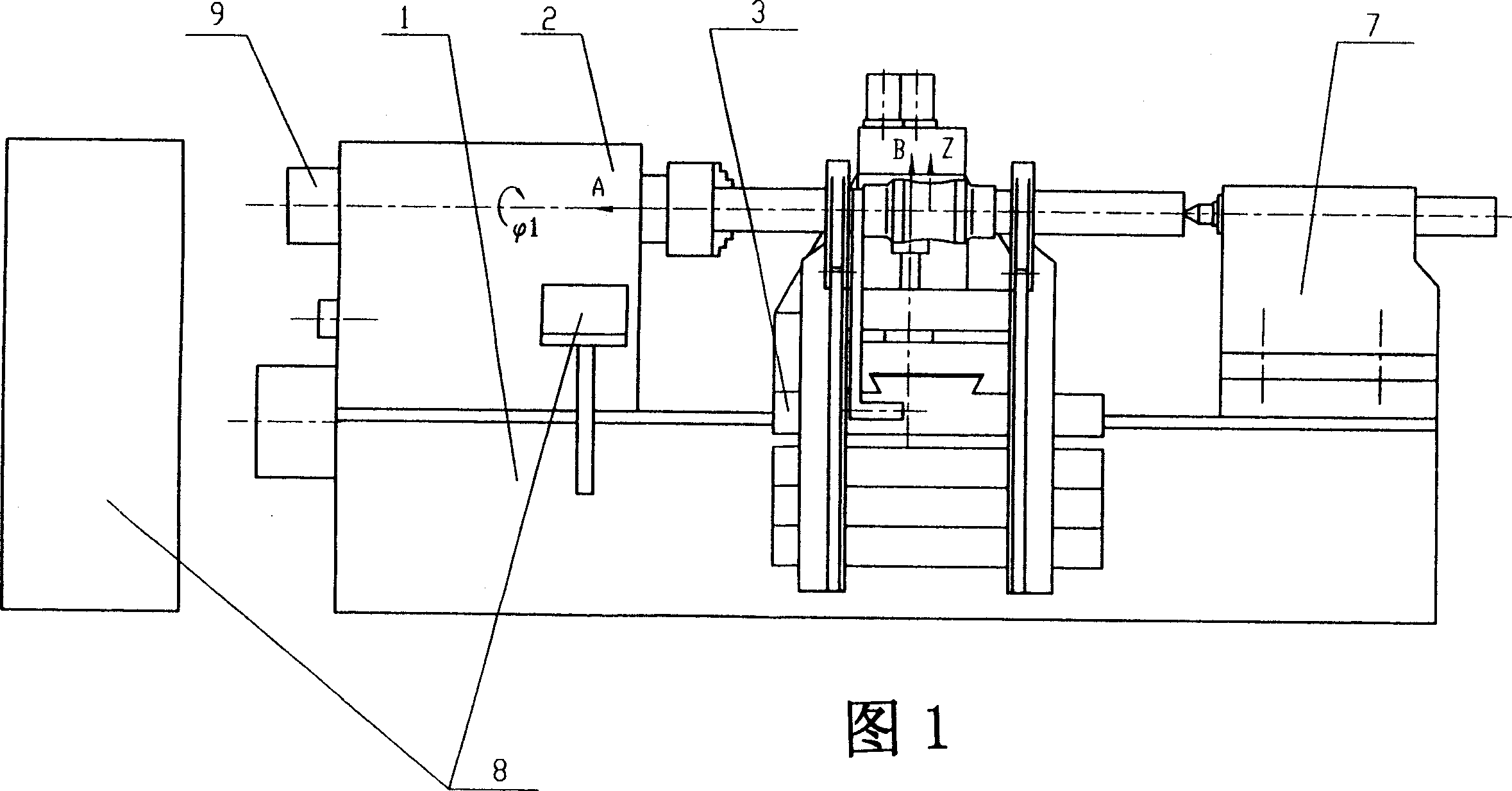

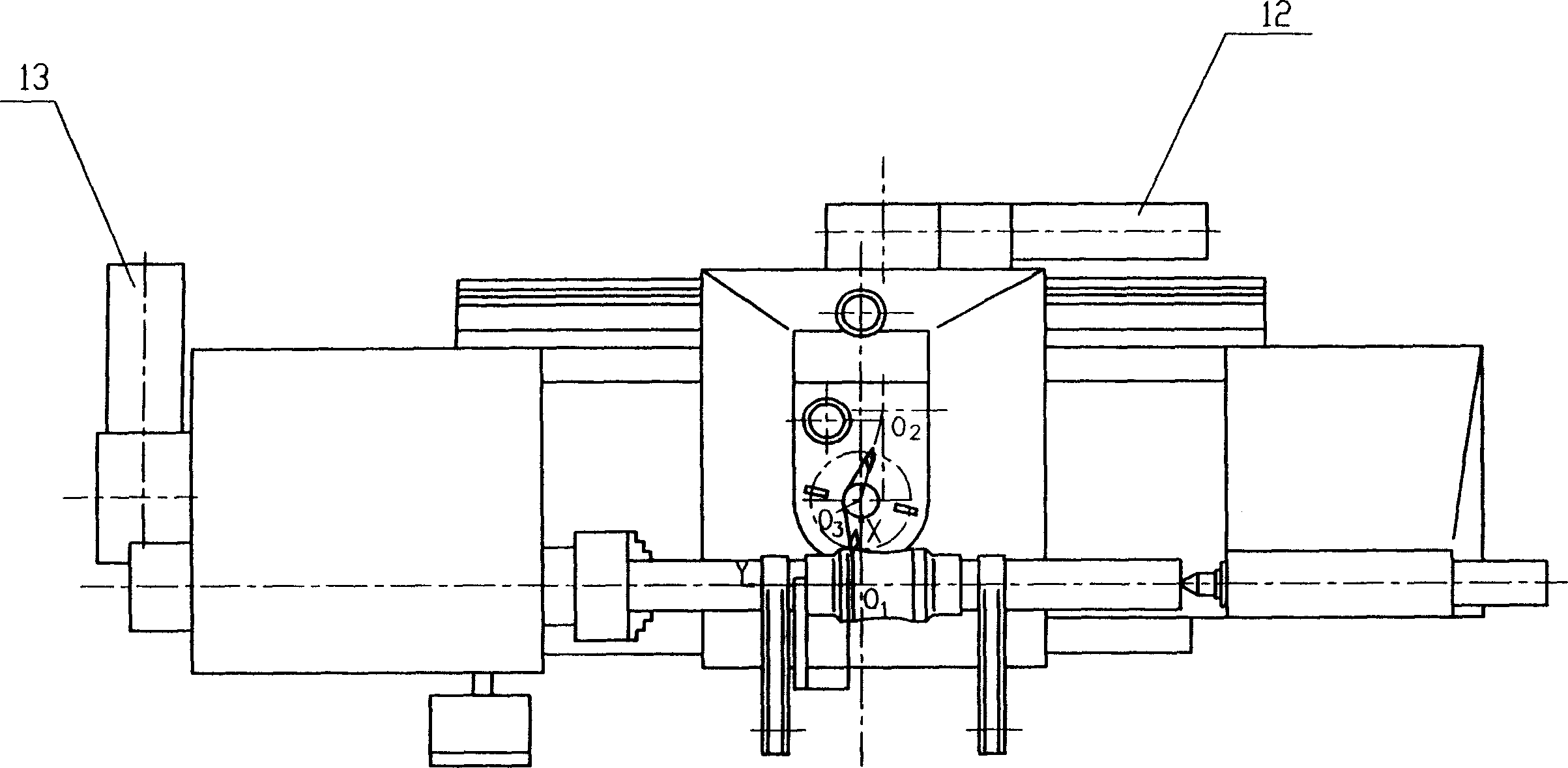

[0028] Embodiment 2: As shown in Figures 1, 2 and 3, the bed 1 is equipped with a headstock 2 and a tailstock 7, the longitudinal slide 3 is installed on the bed 1, the slide 4 is also installed on the longitudinal slide 3, and the vertical guide rail Installed on the sliding plate 4, the tool holder 5 is equipped with a rotary cutterhead, the cutterhead relies on the servo motor 11 to realize the rotation around the B axis, the rotary cutterhead 6 is installed on the vertical guide rail tool holder 5, and the servo motor 10 is used to realize the rotation along the Z axis. Up and down. The rotational speed of the A axis can be automatically selected according to the size and rotational speed of the workpiece, so that the cutting speed of the tool is constant.

[0029] As shown in Figure 7(1), in the five-axis linkage generative motion, the cutting edge of the tool simulates the plane Σ 2 , and ∑ 2 Around K 2 (O 2 ) axis rotation (that is, the rotation of the B axis and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com