Lens sheet and transmission screen with lens sheet

A lens sheet and lens part technology, applied in optics, instruments, projection devices, etc., can solve the problem of damage to plastic panels, achieve high contrast, and avoid damage to image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

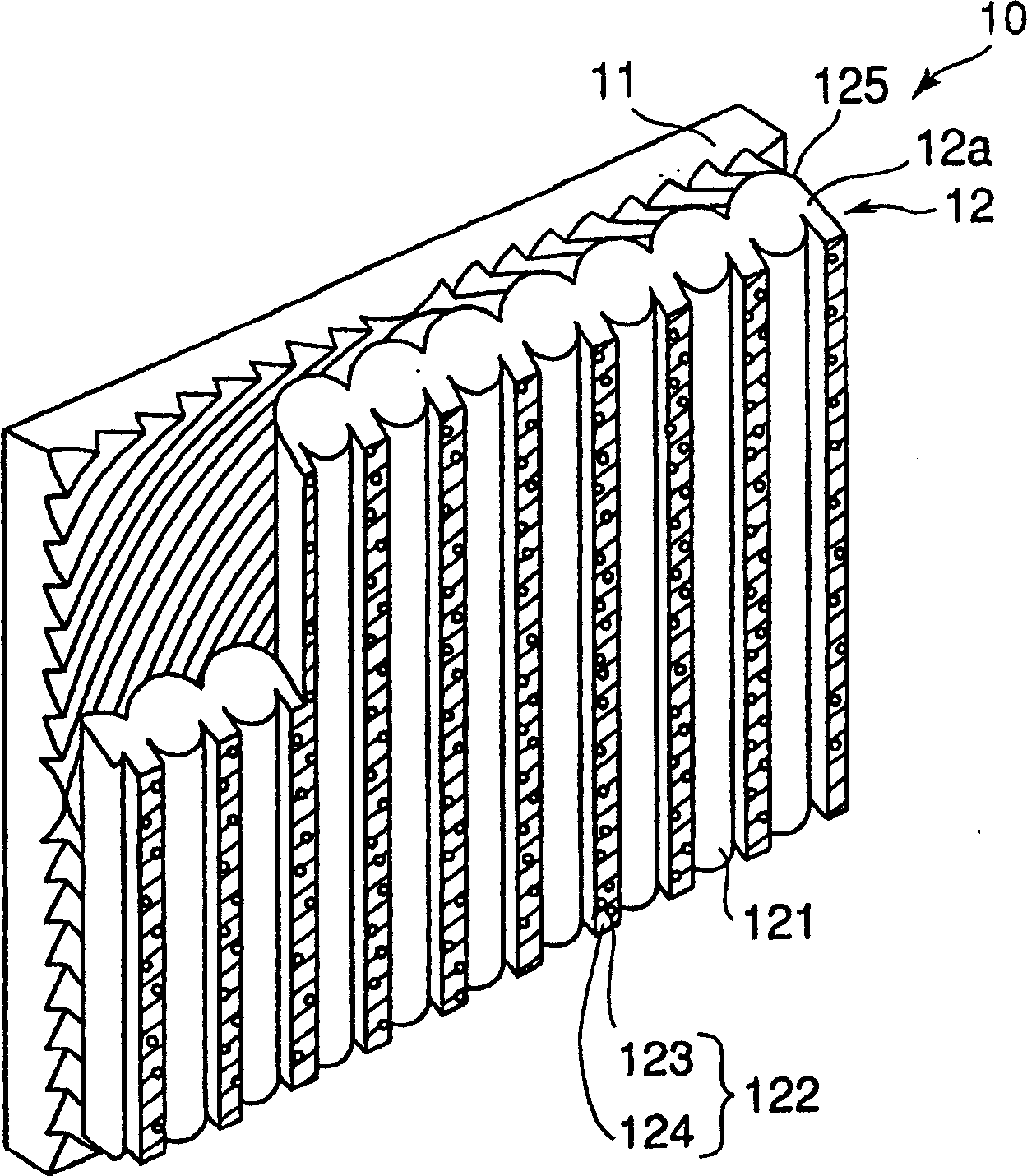

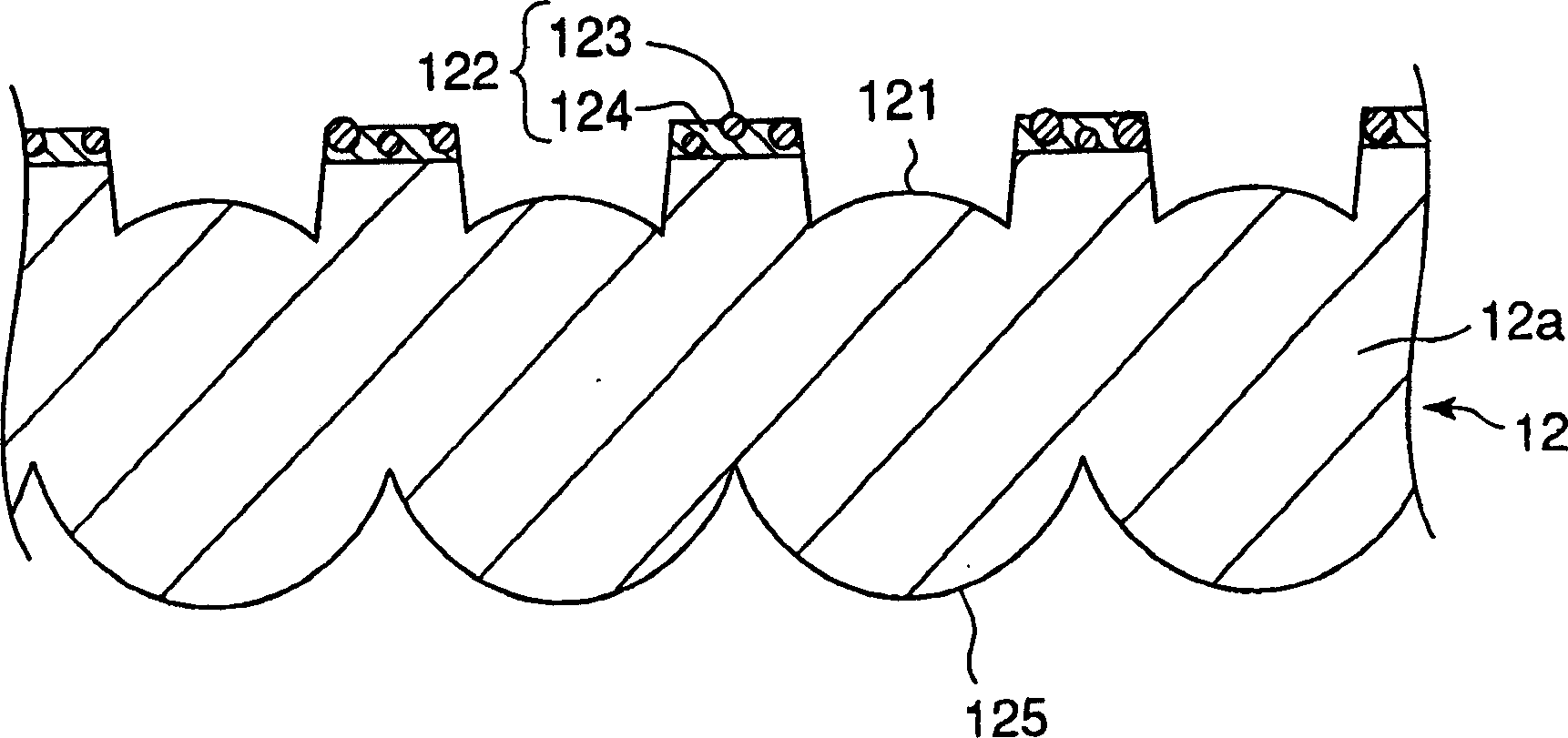

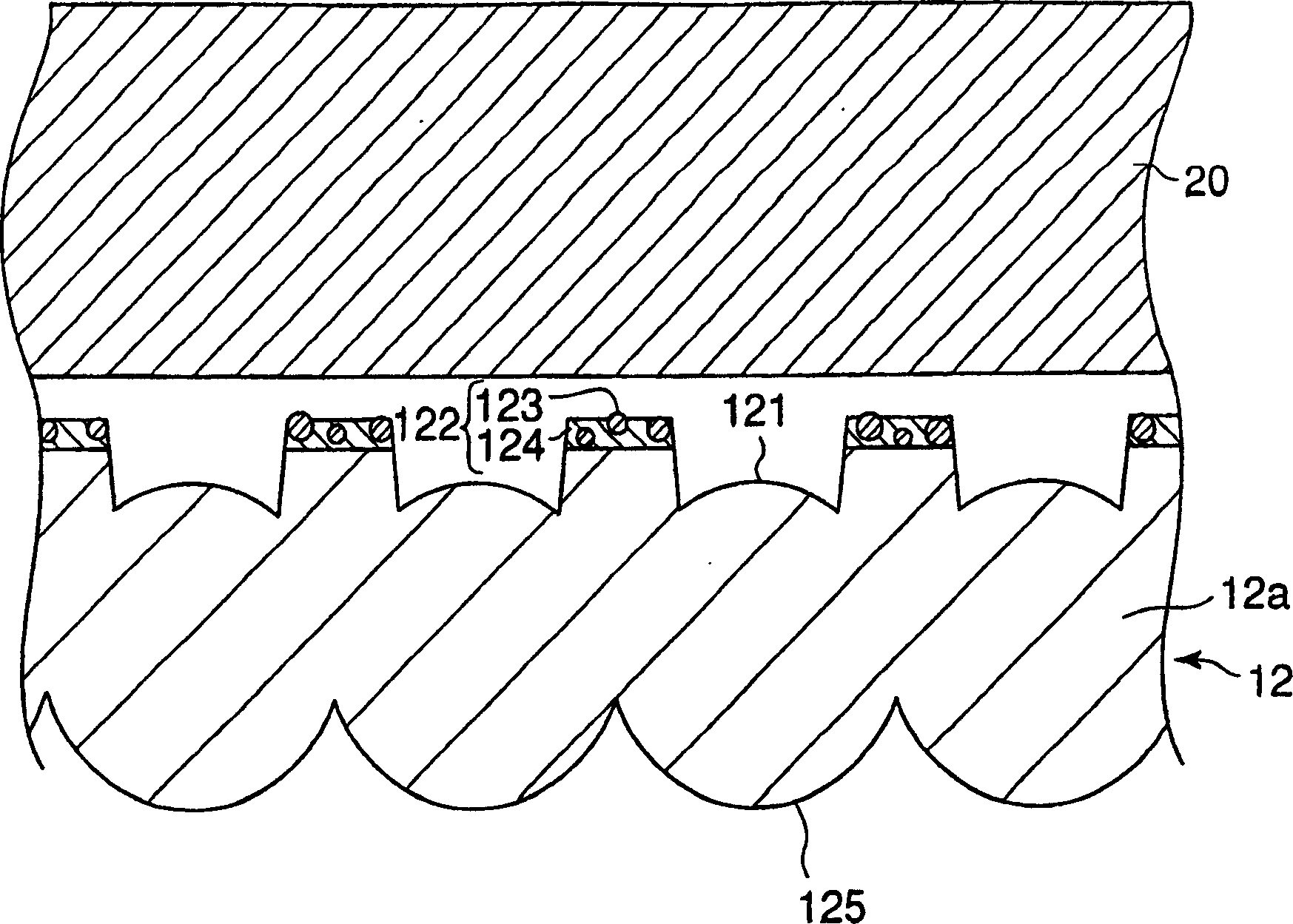

[0072] The lenticular lens sheet according to Example 1 corresponds to the lenticular lens sheet according to the first embodiment of the present invention, and has an external light absorbing portion formed of black ink containing colored light-diffusing particles in a binder resin. .

[0073] As the binder resin forming the external light absorbing portion, an acrylic resin obtained by dispersing fragmented carbon black to 24% by weight was used. Furthermore, as light-diffusing particles contained in the binder resin, crosslinked acrylic pellets containing 8% by weight of carbon black and having a particle diameter of 13 μm were used. The content of the light-diffusing particles contained in the binder resin was 2%.

[0074] Then, in the region where the external light absorbing portion should be formed in the light-exit side surface of the lenticular lens sheet of the double-sided lens sheet, a binder resin containing such light-diffusing particles was printed using the gr...

Embodiment 2

[0077] The lenticular lens sheet related to Example 2 corresponds to the lenticular lens sheet related to the first embodiment of the present invention, and is the same as in Example 1, and has a black ink made of a binder resin containing light-diffusing particles to which coloring has been applied. The external light absorbing part is formed.

[0078] As the binder resin forming the external light absorbing portion, a urethane acrylic resin obtained by dispersing fragmented carbon black at 30% by weight was used. In addition, as light-diffusing particles contained in the binder resin, crosslinked urethane beads containing 20% by weight of carbon black and having a particle diameter of 45 μm were used. The content of light-diffusing particles contained in the binder resin was 10%.

[0079] Then, in the region where the external light absorbing portion should be formed in the light-exit side surface of the lenticular lens sheet of the double-sided lens sheet, a binder resin...

Embodiment 3

[0082] The lenticular lens sheet according to Example 3 corresponds to the lenticular lens sheet according to the second embodiment of the present invention, except that the external light absorbing portion is formed of black ink containing colored light-diffusing particles in the binder resin. , also with a conductive layer with additional conductivity in the external light absorbing part.

[0083] As the binder resin forming the external light absorbing portion, an acrylic resin in which 25% by weight of fragmented carbon black was dispersed was used. Furthermore, as light-diffusing particles contained in the binder resin, crosslinked acrylic pellets containing 15% by weight of carbon black and having a particle diameter of 20 μm were used. The content of light-diffusing particles contained in the binder resin was 15%.

[0084] On the other hand, as a material for forming the conductive layer, an acrylic resin in which carbon black was dispersed at 33% by weight was used. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com