Plastic-flow connector and its connecting method

一种塑性流动、结合体的技术,应用在电动组件、刚性轴联轴器、制造电动发电机等方向,能够解决成本变高、高零件精度、易产生摩擦或咬住等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

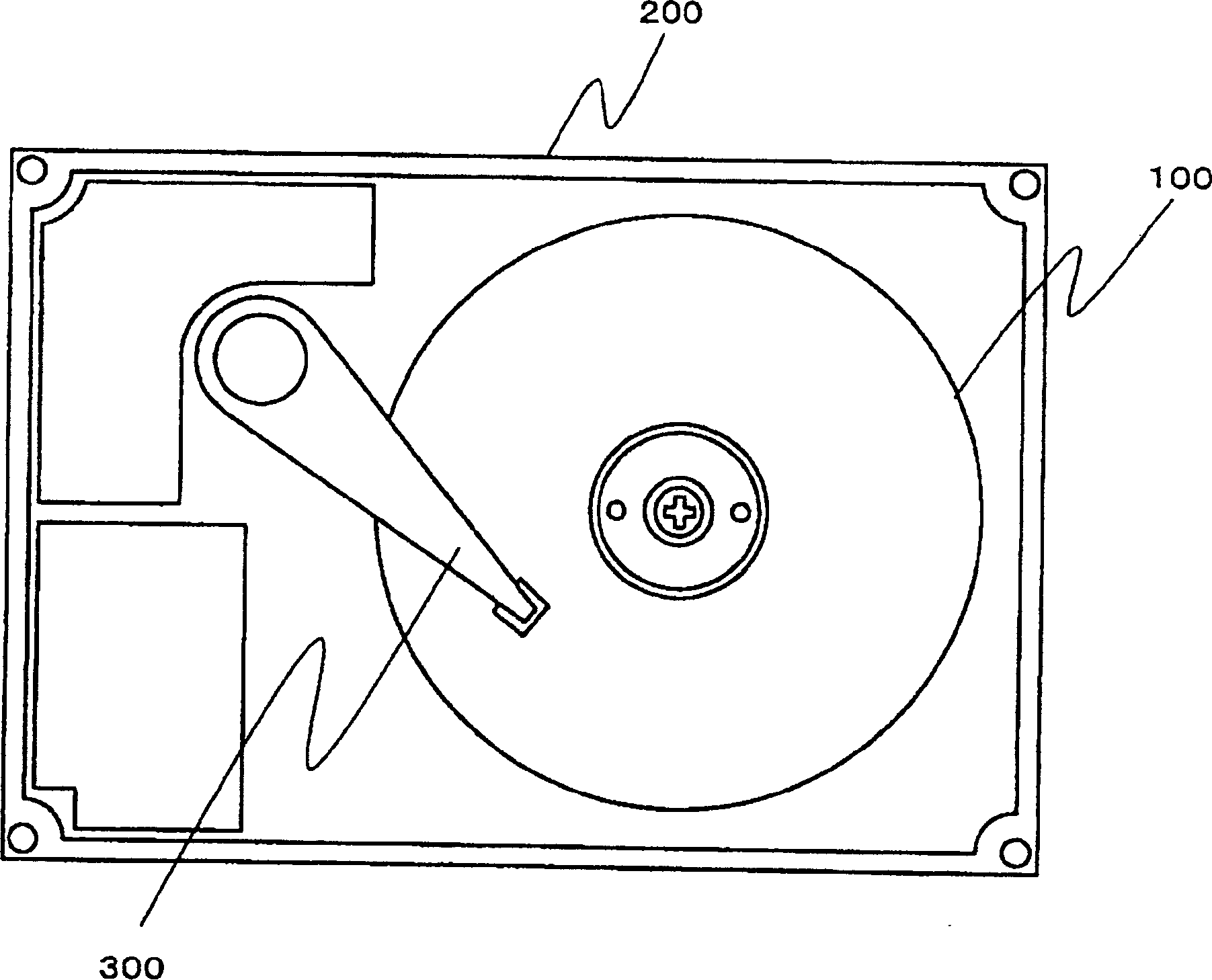

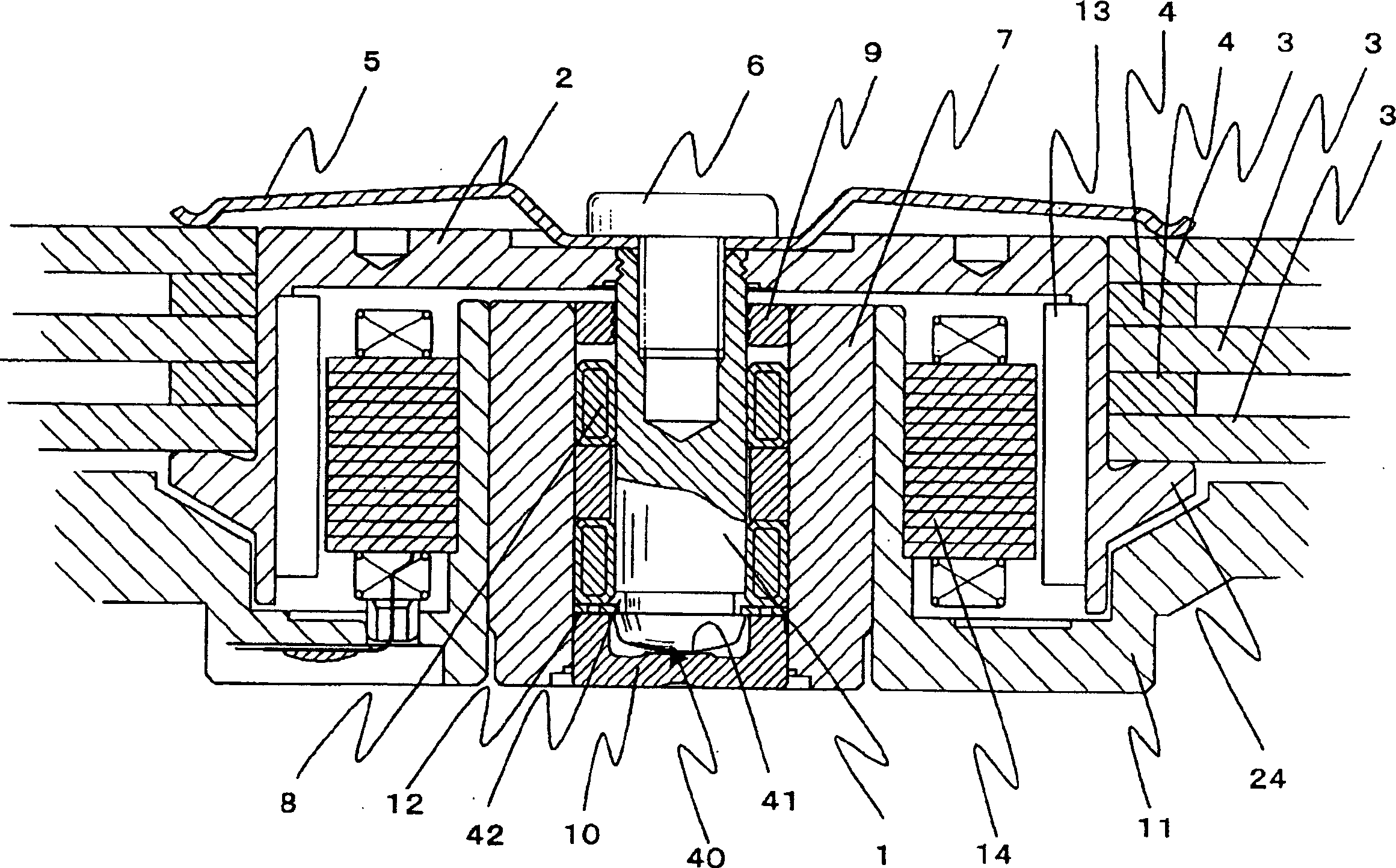

[0029] The present invention is a combination method and a combination, the combination method and the combination are plastic flow bonding spindle motors used in disk devices such as electronic computers, DVDs, and CD-ROMs, especially portable devices such as notebook personal computers. A method and combination of two components such as the shaft and the hub of a spindle motor with a dynamic pressure bearing structure in a thin hard disk drive motor mounted on a computer. As an embodiment of the bonding method and the bonded body of the present invention, a dynamic pressure bearing spindle motor of a hard disk device using a hub and a shaft bonded body will be described as an example.

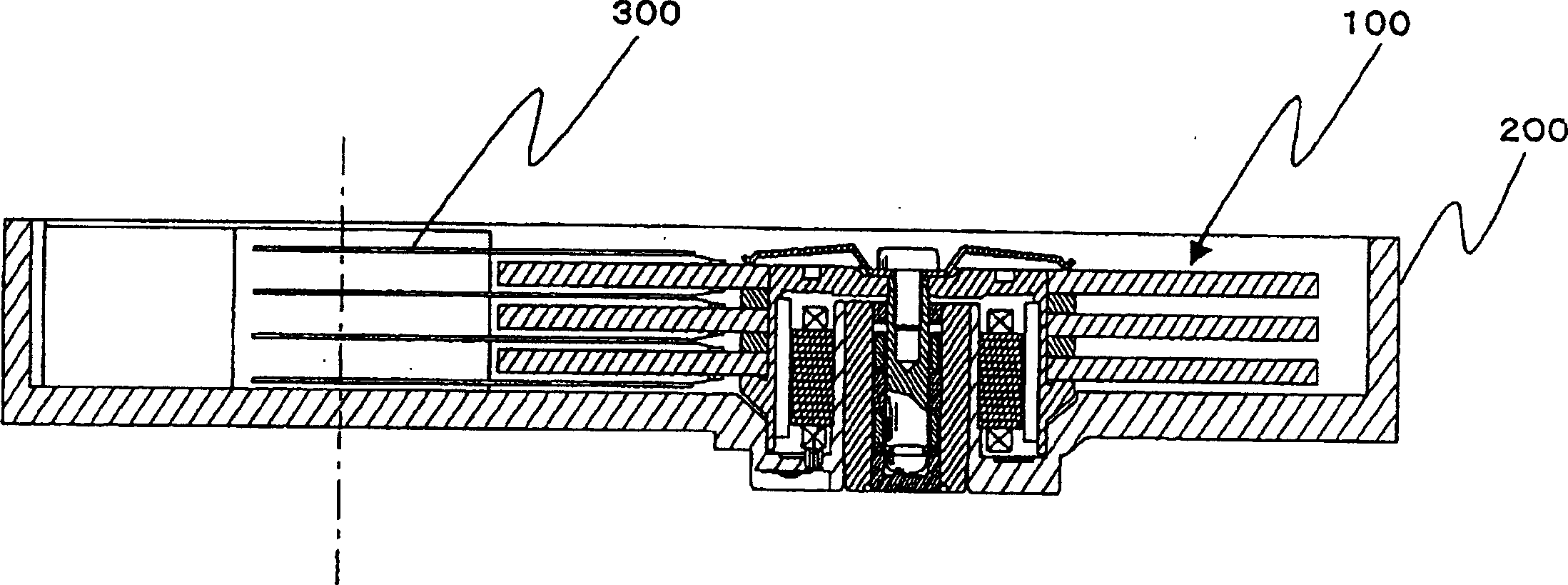

[0030] exist figure 1 , shows the overall view of the hard disk device, in figure 2 Expressed in figure 1 A cross-sectional view of the hard disk unit shown.

[0031] exist figure 1 and figure 2 Among them, 200 is a hard disk device (HDD). In this hard disk device (HDD) 200, the dyn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com